Results 26 to 45 of 45

-

03-12-2015 #26Enthusiast

- Join Date

- Oct 2013

- Location

- N. Indiana

- Posts

- 1,050

-

03-13-2015 #27Enthusiast

- Join Date

- Oct 2013

- Location

- South of London, Surrey

- Posts

- 7,577

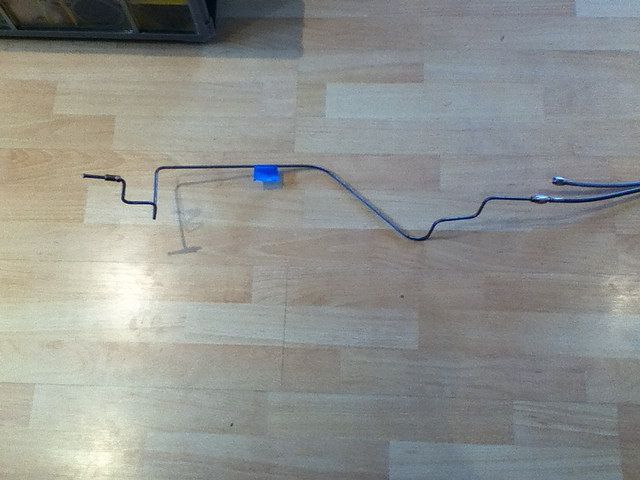

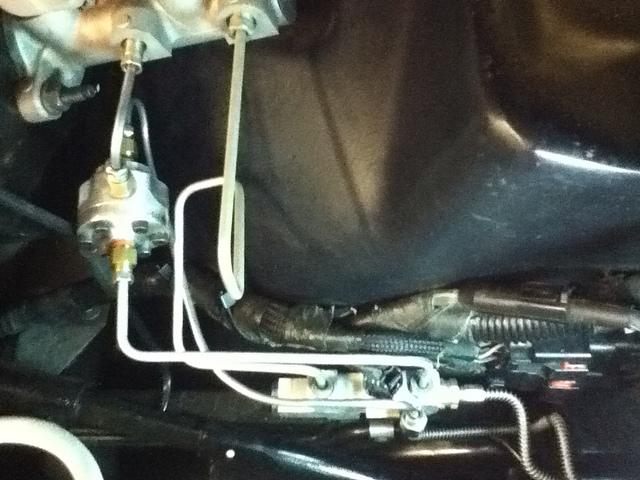

I made up and fitted the brake fluid recycle system for my car with help from Tom & Woodhouse. ( who had some old hard lines left over from their racing days).

Pics here of my set up.

Full album here

https://www.flickr.com/photos/905823...th/8261075548/

Not a 5 minute job doing this mod but I am pleased with the result

I have a few bits left over and would be happy to give advice

-

03-13-2015 #28Enthusiast

- Join Date

- Jul 2014

- Location

- Arkansas

- Posts

- 275

^^^^ Brilliant idea! Saving this for later if track days become a regular occurrence for me. Can you tell much of a difference? Any before and after heat readings?

-

03-13-2015 #29Enthusiast

- Join Date

- Oct 2013

- Location

- South of London, Surrey

- Posts

- 7,577

Only thing I notice is the fluid in the reservoir gets darker quicker because its being recycled. Not much difference in braking pedal feel, but the difference is I no longer get brake fade.

-

03-18-2015 #30

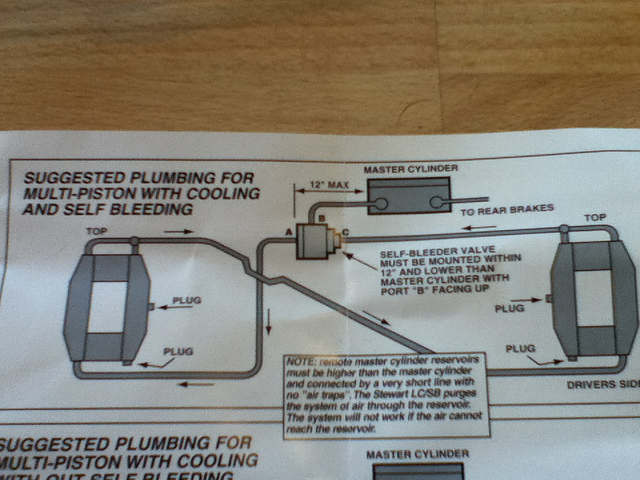

The brake re-circulation is something that's been around a while now. It is a great idea and work really well. The two main benefits to these kits are that 1) The brake fluid is kept cool becuase "fresh" fluid is making it to the caliper regularly. That fluid is cooler and thus less likely to boil. 2) Less likely to have air in the calipers. Since new fluid is "flowing" through, air tends to move out of the caliper if it happens to get there. 3) Bleeding the system is easier since it is done at the recirculator unit.

There are a few out there.

Wilwood calls theirs a "Dynamic Bleed System" - http://www.wilwood.com/PDF/DataSheets/ds213.pdf

DPI makes one - http://www.dpiracingproducts.com/lc-...re-circulator/

I recall Brembo making one but I can't seem to find it now. Also, Outlaw Braking Systems made one as well.

In short, I would consider this for a track car for certain. It's easier and less intrusive to install than a brake cooling duct setup. For a street car... a high boil point fluid should be enough.

By the way... Something that I did not see mentioned... I would not consider a DOT 5 fluid if the car has ABS. DOT 5 is synthetic but it does have a tendency to foam in ABS systems which is a HUGE problem. Non-ABS... not a problem.Luis V.

Miami, Florida

2002 Dodge Viper GTS - FE #298 & 2013 Dodge Viper GTS

-

03-18-2015 #31Enthusiast

- Join Date

- Nov 2013

- Location

- Blair, Nebraska

- Posts

- 3,804

Frankly the number one thing to do with a Gen II is a brake ducting system. Bob Woodhouse designed one years ago and then it was copied by Henry Cone. I believe Jon B. even sold that kit ( Henry's) for years ( who knows he may still have some), but I went from having to flush the brakes three times over a weekend at Mid Ohio on my Gen II ( and eating pads like they were popcorn ) , to the next year never having brake fade and having the pads wear for over two full, long race weekends and another day at a third. This was all accomplished by just doing the brake ducts and I was going faster also . Everything listed here is good, but definitely do the pads as the laminar flow of air over the Gen IIs just don't allow much to get to the rotors.

Last edited by Bill Pemberton; 03-18-2015 at 05:21 PM.

-

03-21-2015 #32Enthusiast

- Join Date

- Jun 2014

- Location

- Long Island, NY

- Posts

- 874

Any thoughts on this stuff? I'm about to buy it. Says ideal for ABS and has high boiling point for heavy street, light track.

-

03-21-2015 #33Enthusiast

- Join Date

- Nov 2013

- Location

- Chandler, AZ

- Posts

- 2,463

If you are doing HPDE track days, then I would go for Motul RBF 600. What you posted seems good for street use since it lasts longer than the more hygroscopic RBF.

link: Is DOT 5.1 right for you?

-

03-21-2015 #34Enthusiast

- Join Date

- Oct 2013

- Posts

- 930

I use Porsche Racing Brake Fluid in my CC. Just down the block, always in stock..

-

03-21-2015 #35Enthusiast

- Join Date

- Nov 2013

- Location

- Chandler, AZ

- Posts

- 2,463

It would be interesting to learn more about what the product you are buying is. The P-guys talk about Endless RF-650 being the OE for the GT3 cup cars. Supposedly better than Castrol SRF for wet boiling point and compressibility and pedal feel.

http://rennlist.com/forums/racing-an...ml#post6653847

-

04-13-2015 #36Enthusiast

- Join Date

- Oct 2013

- Location

- New Braunfels, TX

- Posts

- 1,836

When does a late-model 911-based car EVER have brake problems?

-

04-13-2015 #37Enthusiast

- Join Date

- Oct 2013

- Location

- Up The River..[Columbia River Gorge near Portland OR]

- Posts

- 3,726

-

12-28-2015 #38Enthusiast

- Join Date

- Dec 2013

- Location

- Franktown, CO

- Posts

- 203

Thanks for relevant information on a similar plumbing problem I'm dealing with.

First, I inherited this configuration, I didn't plumb it. Seems to have somewhat survived several years of me and the track...

Second, my brother and I are using the cold winter days to upgrade brakes to a StopTech 4x4 BBK, replacing a Wilwood setup which also included this recirculation setup you have pictured. On to the questions:

1.) A bit hard to make out on the pics here or flickr, but how is the system plumbed aft of the proportioning valve? My "self bleeder valve" output is plumbed directly into the "front" side of the proportioning valve, as yours seems to be. From here, things get a little questionable on my setup. My left front brake output from the proportioning valve is blocked off with a cover... The right front output of the prop. valve goes to the right front brake via the stock brake line. As depicted in the above diagram, I have a "crossover" flex-line from the right front to the left front brake, and the return to the "bleeder valve" is then from the left front brake. No prop. valve in the above diagram - or other diagrams. Other diagrams, and general logic may indicate that feeding both calipers simultaneously and having simultaneous (bridged) returns would be best..??

2.) With the plumbing of the above diagram, aren't I just really pushing hot fluid from one caliper to the other, since there is no common feed/return from each caliper? Case in point, my left front rotor (downstream of the first caliper) was cracked upon close inspection - could be the additional heat coming from the other side that contributed..?? We'll never know, but a thought.

3.) Is the heated fluid at the top of each caliper the main reason to tie the 2 bleeders of the calipers together for the fluid "output" from each caliper?? Seems logical and makes sense, but aside that response I have to ask why I cannot use the 2 existing bleeder ports as the gozinta/gozouta ports. The existing bottom crossover tube from the factory is so neatly bent and fit, I hate to have to remove it...

4.) It looks like there are machined bosses in the inboard side of the calipers to be used as anchor points for the new input line I'll have to come up with. I'll hope to be on the phone with StopTech this week, but if you have any input into new ideas of flexline and connection blocks, I'd be happy to listen.

5.) As for the back brakes... Also plumbed in is an adjustable bias valve for the rear brakes. I'm OK with this in concept, but I'm not sure why it's plumbed just before the proportioning valve. It would seem that this is really only serving as an additional bias valve, perhaps serving no real purpose. As I understand things, the stock prop. valve is wide open to the rears on light braking, but with increased foot pressure (and forward weighting of the car), the valve kicks in to limit the rear pressure, on some logarithmic scale. Isn't what I currently have plumbed a bit self defeating, or am I crazy?

6.) Perhaps the real question here is whether to run the stock proportioning valve with the StopTech setup and just use the rear bias valve?? Another good question for StopTech, but I'm all ears to your input.

7.) Any regrets with running the recirculation system?? Any system failures to report??

Thanks in advance for the response to my questions.

Mike

-

12-28-2015 #39Enthusiast

- Join Date

- Oct 2013

- Location

- South of London, Surrey

- Posts

- 7,577

Hello Mike,

Well I will answer the easy question first. No7, Any regrets with running the re-circ system ...........NONE.

Is there anything I would do slightly differently if I did this again......YES, It would be to fit the brake line to the side of the caliper body If you look at Tom's diagram and then look at the diagram I copied you will see Toms lines go into the side plugs of the caliper.

Why would I change this........Well having done a few track sessions I have noticed on my Left hand caliper the line is showing some signs of abrasion(directly below the caliper body) from the odd stone being flicked around off the disc, as the wheel spins things would be thrown outwards so having the line at the lowest point of the caliper its likely to get hit by the odd bit of gravel.

Don't get me wrong, everything is working just fine but I do check the lines regularly to make sure its all good, (just something to be aware of).

No6 and No5, I am using 13 inch rotors and the stock proportioning valve, I believe the Big Brake Stoptechs use a different proportioning valve? Sorry to say I have no experience of this so could not advise the best route forward.

No4, I would use those central inboard Bosses and get your new lines made up with the correct Banjo fittings One thing I would advise is to keep checking the flexi brake line clearance by turning the steering back and forth on full lock each way making sure there is no risk of the lines rubbing on the wheel or the lines interfering with the suspension set up, this took me sometime to get right and why if you look a my pics I added some rubber sleeving midway along the flexi lines for added protection. Getting a brake line custom made 1" longer of shorter can make a hell of a difference!

One thing I would advise is to keep checking the flexi brake line clearance by turning the steering back and forth on full lock each way making sure there is no risk of the lines rubbing on the wheel or the lines interfering with the suspension set up, this took me sometime to get right and why if you look a my pics I added some rubber sleeving midway along the flexi lines for added protection. Getting a brake line custom made 1" longer of shorter can make a hell of a difference!

No3 The two pipes coming off the top of the caliper bodies is to let any trapped air out of system and to make sure fluid is pushed around the caliper correctly, I dont think its to do with heat?

No2 Yes you are pushing fluid around from one caliper to another But, as the fluid is being pumped around slowly it has time to cool in the pipes a few degrees before going into the next caliper and then returning to the Master Cylinder. Sure you are only talking a few degrees but it works Its better than having the same fluid getting heated up time after time and the BEST BIT is its self bleeding.

Its better than having the same fluid getting heated up time after time and the BEST BIT is its self bleeding.

No1, OK I will try and explain my set up,

Look at my diagram, Look at the recycle valve and note port C this one,

From Port C my line goes to a double inverted connector Its basicly a piece of hex tube with two brass flares inside the tube that the pipe connects to

You can see the top of it right next to the oem proportion valve

Here is a better shot

The Original brake pipe with the coiled wire around it is removed from the front bottom hole of the OEM proportioning valve and a blanking cap is fitted in place, then the coiled brake pipe is inserted into the hex double inverted flare tube to complete the link.

Port A from the recycle valve goes to the top front hole of the OEM Proportioning valve.(you can see this in the centre pic) From what you are describing we both have a similar set up, the only difference is you are using flexi braided brake lines as opposed to my made up Hard lines.

Having Just looked again at Toms Diagram, Tom also used flexi braided return lines with a T piece fitting (I used the Double inverted flare connector instead).

I have not touched the rear brake side of the OEM proportion valve as I am still using the "Toms 40mm Little brakes that can"

I will also fit the Brake ducting for this coming season, seems like a win win to me

Last edited by Fatboy 18; 12-28-2015 at 05:27 AM.

-

12-28-2015 #40Enthusiast

- Join Date

- Nov 2013

- Location

- Chandler, AZ

- Posts

- 2,463

I have no personal experience in this; but, I had run across the following video by a company that makes/markets the valves. Their diagram seems more like what you are proposing. They have 2 configuration diagrams in their catalog for 2 different levels of cooling efficiency.

https://www.youtube.com/watch?v=0A0WiPFEsRwLast edited by AZTVR; 12-28-2015 at 12:28 PM.

-

12-28-2015 #41Enthusiast

- Join Date

- Oct 2013

- Location

- South of London, Surrey

- Posts

- 7,577

Good find

-

01-04-2016 #42Enthusiast

- Join Date

- Dec 2013

- Location

- Franktown, CO

- Posts

- 203

Fatboy,

Interesting that the plumbing is the same as mine, with the exception of which front port on the original prop valve is blocked, and the direction of your flow. I didn't see that when first looking at your setup, thanks for taking the time to clarify.

After digesting too much input from the inter webs, and finally some clarifying input from Mark @ IPSCO, I'm headed down the "simplify" road. For now, I'm removing the recirc system and the stock prop valve. I'll use Motul 600 and bleed the brakes religiously, counting on those big StopTechs to do their job as a heat synch. Although I'll miss the convenience of just pulling old fluid out and replacing with new, perhaps it will convince me to finally buy the 1/2" rechargeable impact driver...

Mark sells a nice setup with pre-bent lines, bias valve and front splitter all attached to a mounting plate where the old prop valve mounts. Since I'm in the middle of the brake job, all I have is a pic of the unit yet to be installed. New thread and more pics when I'm finished, but I wanted to include this fine piece of work from Mark. Third pic is my cracked rotor...

image.jpg

image.jpg

image.jpg

-

01-04-2016 #43Enthusiast

- Join Date

- Oct 2013

- Location

- South of London, Surrey

- Posts

- 7,577

Looks like your disc has got very hot? The cooling ducting would help with that

Looking forward to reading and seeing more pics of the new set up

For the record, I do not have any problem with the Brake Bias or (Balance) on my car. The Stock front calipers and Toms 40mm rear calipers work fine. I can still get front wheel lock up but its nowhere near as bad as it was before installing the 40mm calipers.Last edited by Fatboy 18; 01-04-2016 at 02:47 AM.

-

01-04-2016 #44Enthusiast

- Join Date

- Dec 2013

- Location

- Franktown, CO

- Posts

- 203

((Spell Check)+(Beer))="Heat Synch"... Sorry, meant heat sink.

I do have ducting to the brakes... Hmmm. Perhaps several other factors contributed:

1.) Wilwood solution is/was probably undersized for this car, but better than the stock setup for its time in history.

2.) Solution was at the end of its useful lifecycle. The Wilwood rotors are not serviceable items, they are not to be turned - only replaced...

3.) I motored thru 3 sets of Wilwoods most aggressive street/strip pad for this application (BP-20) just this season. The last time I changed pads (and inspected things) was also the time I switched to a more aggressive race pad. I only had the car on the track once with these newer pads, and although the pads didn't show too much wear, I can somewhat assume that the rotors took a bit more of the abuse during the sessions.

4.) This particular rotor is/was the downstream rotor in the recirculation flow. Just an observation here.

-

03-15-2016 #45Enthusiast

- Join Date

- Mar 2016

- Posts

- 1

http://karlperformance.com/p/PSF12P-...t-Bottle/24777

I use this Power Steering Fluid

Reply With Quote

Reply With Quote

Bookmarks