Excellent! Thanks for the update. This thread needs to be turned into and article in the new Viper Quarterly lol.

Mine also is running great no issues to report.

Results 301 to 325 of 405

-

02-17-2014 #301Enthusiast

- Join Date

- Oct 2013

- Location

- Montgomery Texas

- Posts

- 6,732

-

02-17-2014 #302Enthusiast

- Join Date

- Oct 2013

- Location

- Montgomery, Texas

- Posts

- 1,251

I did the same. I haven't had to re torque since the 1st heat cycle. I'll have to get it on the dyno. I just put hi-flow cats on so that will skew my results a bit though.

-

02-17-2014 #303Enthusiast

- Join Date

- Nov 2013

- Location

- Indianapolis

- Posts

- 1,256

For you guys that have been driving on your Gen V intakes for a while now, do you feel after re-torquing that throttle response has returned to baseline or better or is there still a lag?

-

02-17-2014 #304Enthusiast

- Join Date

- Oct 2013

- Location

- Montgomery Texas

- Posts

- 6,732

-

02-22-2014 #305Enthusiast

- Join Date

- Nov 2013

- Location

- Lucas, Texas

- Posts

- 2,009

Another 100 or so miles on mine. Perfect.

-

05-22-2014 #306Enthusiast

- Join Date

- Oct 2013

- Posts

- 516

I jumped on the GenV intake swap bandwagon today. Huge thanks to Andy and all the others who blazed this trail. Your "lessons learned" were extremely helpful. My install went without a hitch. The most stressful and tedious part of the whole thing was torquing the bolts. I must have gone through torque sequence at least 10 times all the while cringing and pleading with the torque wrench to "click". After having gone through it, I would not go to 106 inch/lbs again. ~85 is more than enough in my opinion given that the torque limiters do nothing to limit torque after trimming them. It seemed like all I was doing once the manifold was fully seated was crushing the plastic.

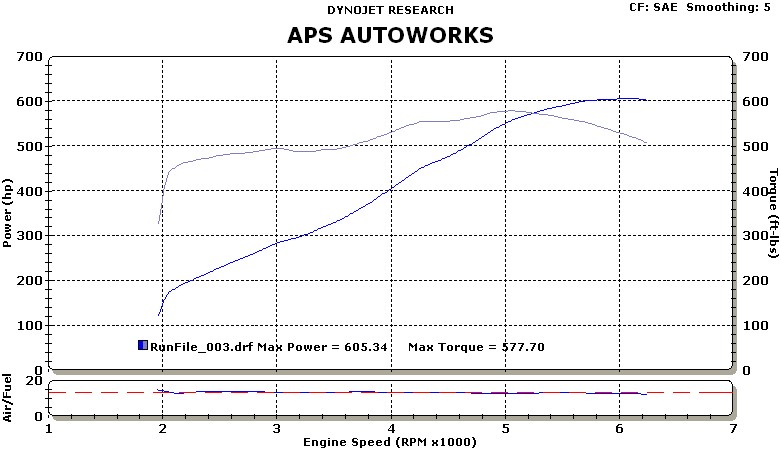

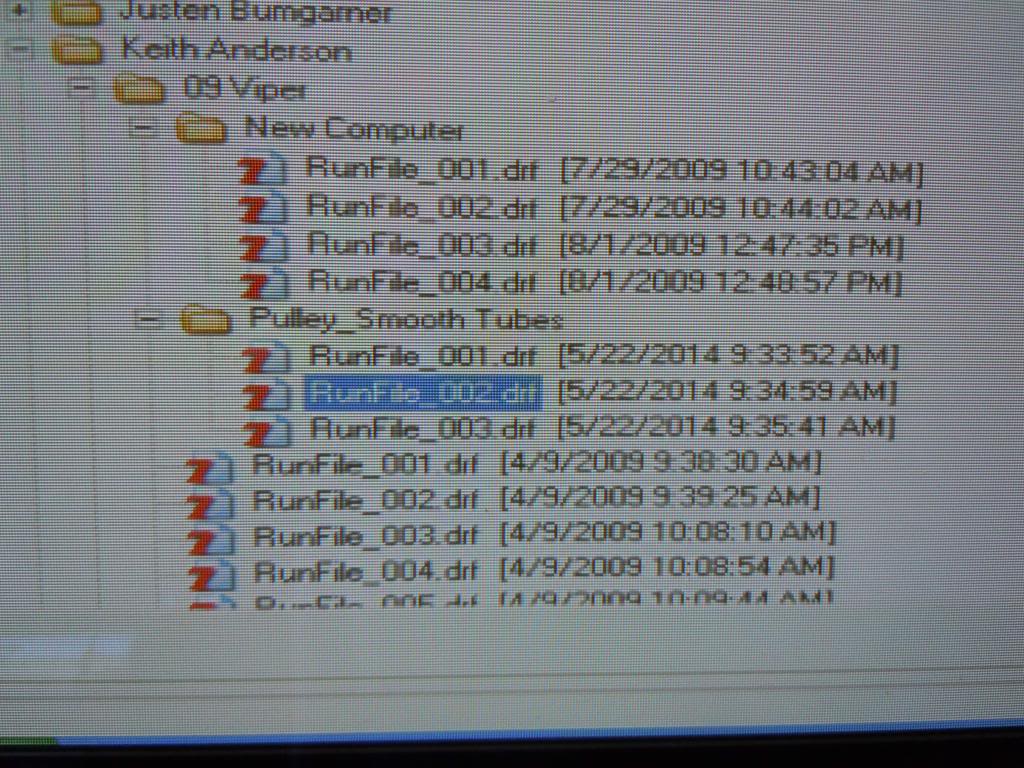

I made three base dyno pulls after a 30 minute cool down while the car was strapped down and I swapped in the smooth tubes. First pull was 602.xx. Second was 603.xx, and the third was 605.34. I was kind of stunned. Last time I dynoed the car it made 585 or so I thought. This was after installing the Mopar ECU. My before ECU hp was also 585. A 18 hp gain from an underdrive pulley and smooth tubes seemed very optimistic. So I questioned the results and he brought up my previous graphs and low and behold, it pulled 593 last time after the Mopar ECU install. I'm going to examine the graphs again but it looks like I may be eating some crow as I've been bad mouthing the Mopar ECU all this time for a zero hp gain. Apparently, there was some communication breakdown or more likely, I was confused. While 8 hp isn't great, it's better than nothing. I was also under the impression that I lost hp everywhere else under the curve. Like I said, I'm going to be studying those graphs again.

While 8 hp isn't great, it's better than nothing. I was also under the impression that I lost hp everywhere else under the curve. Like I said, I'm going to be studying those graphs again.

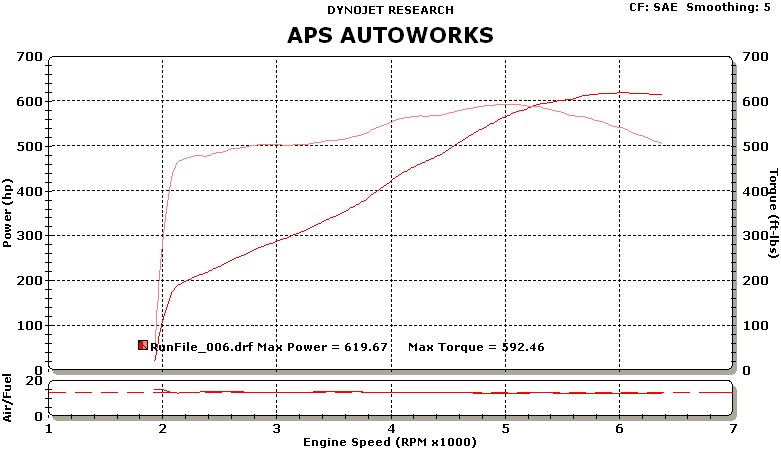

On to the swap. It took me two hours. I went for a quick 15 mile spirited drive to make sure everything was okay. Nothing funky happened. No check engine lights, no problems. Strapped her back down on the dyno and waited 30 minutes like the first time. First pull was 616.xx, second 617.xx, third 619.67hp and 593.46tq. Since it kept climbing I gave it a 4th pull to try and top 620 but was denied. Fell back to 617 so I quit. AF was in the 12.5 to 12.7 range at peak hp if I remember correctly. There was a 25hp gain at 4000 rpm. Didn't really look much more in detail. He was very busy today and it's basically a one man shop so I didn't want to waste too much of his time. I'll get him to send me some overlays later. In the meantime, here are the best pulls from today, pre manifold and post manifold.

My mod progression has been:

M&M headers and my own exhaust system: 585hp 565tq

+K&N replacement air filter and Mopar ECU: 593hp ??tq

+Underdrive pulley and smooth tubes: 605.34hp 577.7 tq

+GenV intake manifold: 619.67hp 592.46 tq

The snake has 12,8xx hard miles on it. I'm very happy to know she's as strong as ever.

All runs have been on the same dyno with the same operator. All numbers are SAE. I asked Todd today if his dyno is generous and he said no, it's on par with other Dynojets.

I wasn't able to dyno the car bone stock unfortunately. M&M needed a Gen4 car to R&D their headers so I let them have it for a month in the winter of '09 just a couple weeks after I bought it. They installed the first set they ever built in my car and they have been in place ever since.

Some pics from today:

-

05-22-2014 #307Enthusiast

- Join Date

- Nov 2013

- Location

- Lucas, Texas

- Posts

- 2,009

That is friggin stellar BIB! Thanks for sharing your experience.

FWIW, mine is still kicking ass and taking names with zero issues. Raced the car all day Sunday in the Texas sun without a single hiccup.

-

05-22-2014 #308Enthusiast

- Join Date

- May 2014

- Posts

- 55

We've done this as well on my Gen4 race car.

We milled down the "torque limiters".

We also had to re-torque it after heat cycles as well.

I picked up about 15hp across the board.

The lower intake air heat saturation is a major benefit of this intake.

-Keith@HPTuners

-

05-22-2014 #309Enthusiast

- Join Date

- Oct 2013

- Posts

- 3,494

Good stuff!

-

05-22-2014 #310Enthusiast

- Join Date

- Oct 2013

- Location

- Minnesota

- Posts

- 444

way to go Keith. Those are some great numbers... Now I guess I will have to jump on the bandwagon.

-

05-22-2014 #311Enthusiast

- Join Date

- Oct 2013

- Location

- Montgomery Texas

- Posts

- 6,732

Excellent! Thanks for the update and glad you're happy!

-

05-23-2014 #312Enthusiast

- Join Date

- Jan 2014

- Posts

- 37

Nice numbers Back-In-Black. are you going to port your heads ?

-

05-23-2014 #313Enthusiast

- Join Date

- Nov 2013

- Location

- Indianapolis

- Posts

- 1,256

Excellent results. You 620 guys are making me jealous. Mine is just a stingy *&%ˆ$. I did a write up on this install in another section of the forum. I torque min to 80 in-lbs for exactly the reason you stated and used larger washers under the bolt heads.

-

05-23-2014 #314Enthusiast

- Join Date

- Oct 2013

- Location

- Montgomery Texas

- Posts

- 6,732

-

05-23-2014 #315Enthusiast

- Join Date

- Nov 2013

- Location

- Indianapolis

- Posts

- 1,256

-

05-23-2014 #316Enthusiast

- Join Date

- Oct 2013

- Posts

- 516

-

07-09-2014 #317Enthusiast

- Join Date

- Apr 2014

- Location

- Texas

- Posts

- 197

There is a blue gen iv acr at the archer shop with a gen v intake, does the car belongs to any of you guys?

-

07-10-2014 #318Enthusiast

- Join Date

- Oct 2013

- Posts

- 516

-

07-10-2014 #319Enthusiast

- Join Date

- Apr 2014

- Location

- Texas

- Posts

- 197

Yup that's the one.

-

07-23-2014 #320Enthusiast

- Join Date

- Jul 2014

- Location

- Orlando, FL

- Posts

- 33

Hello everyone, I would like to give a shout out a few members here for the inspiration to do the manifold swap, FLATOUT, INDYRON, FRGMSTR. I did the install, gen V manifold and oil catch can from Radium, over the weekend. I did not disconnect the battery during install and car started back fine without any errors. I ran the car three times now had to re-torqued the bolts after each. photo 2.jpgphoto 3.jpgphoto 1.jpgphoto 4.jpgphoto 5.jpg

-

07-23-2014 #321Enthusiast

- Join Date

- Oct 2013

- Location

- Montgomery Texas

- Posts

- 6,732

-

07-23-2014 #322Enthusiast

- Join Date

- Nov 2013

- Location

- Indianapolis

- Posts

- 1,256

Strong work buddy! I didn't reset my computer either. Keep in mind that it is likely that the factory computer will pull timing on the top end to limit power above 5krpm unless you have the Mopar PCM or aftermarket tune. That said, even with the stock tune, you are still picking up 20/20 in the midrange. Enjoy it!

-

07-23-2014 #323Enthusiast

- Join Date

- Nov 2013

- Location

- Lucas, Texas

- Posts

- 2,009

Looks right at home with the red! I would suggest there is nothing to be gained by retorquing the bolts though. I retorqued mine ONCE and all has been perfect with it. No sense in putting a lot of extra clamping force on a plastic part since that will cause the material to flow over the long haul. I used to work in the plastics industry and while that composite is not likely to flow much, I still would not want to see it crack either however.

I have had my thumb up my but when it comes to doing my catchcan as it is still sitting on my workbench. I always see those Radium catchcan pics then look at the price and always back up a bit.

-

07-23-2014 #324Enthusiast

- Join Date

- Jul 2014

- Location

- Orlando, FL

- Posts

- 33

-

07-23-2014 #325Enthusiast

- Join Date

- Nov 2013

- Location

- Lucas, Texas

- Posts

- 2,009

Reply With Quote

Reply With Quote

Bookmarks