Introduction

The 2-3 people that follow me on Instagram (@sidepipedsnake) have figured out that I’ve been busy lately rebuilding the differential in my ’08 Viper. There is nothing new about what I’m doing – as a matter of fact, Viper owner Bryan Cowger (a.k.a. “cowger”) did exactly what I set out to do about 10 years ago, and he was kind enough to document his adventure here:

https://www.viperclub.org/vca/thread...change.659129/

Unfortunately, as is the case with many great write-ups on various forums around the internet, his pictures no longer work (many thanks, and a hearty f*** you to Photobucket). I reached out to Bryan through the forum, and he was kind enough to email me every single one of his pictures, which was hugely helpful. It is not my intent, however, to recreate his old thread. I can do that at a later date when/if I get the time and have his permission to do so, but now is not that time.

Even after going over and over his posts and scouring the internet for hours on end sifting through the information that’s out there (both good and bad), I still had so many questions to which I had no answers. I’ve spent the better part of the past 2 months working on this project off and on as time permitted, and I’ve learned so many things along the way. My intent is to share what I’ve learned with the broader Viper community in hopes that it will inspire other owners, much like Bryan inspired me, to tackle this job.

Background/Motivation

First and foremost, this rebuild was not done out of necessity. I am fortunate to have two complete differentials in my possession – the one that originally came with my car with 3.07 gears and the stock GKN Visco Lok, and a fully assembled Gen 5 differential (w/ 3.55s and the same GKN Visco Lok) I ordered and installed about 5 years ago, documented here:

https://driveviper.com/forums/thread...ial-in-a-Gen-4

Drag radials were not kind to my original differential – when I took it out back in 2017, it had some pretty serious gear whine, and was making noises that were not comforting. Once the Gen 5 differential arrived on my door step, I took the original one out and ended up storing it in my shed, knowing that one day it would need a rebuild.

The Gen 5 differential has held up to a substantial amount of abuse, and although it has picked up some gear whine over the past few years (mostly thanks to Hoosier drag radials and the Nth Moto clutch), it continues to work without issue. After this little experiment, it will also go into storage, and I may end up refreshing it at some point in the future now that I have the knowledge/tools/skills to do it myself.

Rebuilding a differential is one of those things that has always seemed a little beyond my ability to tackle, but I also don’t know of any shops around me that would take on the job, or if they would, do it to my satisfaction. Time is money, and shops need to make a profit, but as I have learned, rushing a differential rebuild is not something anyone should do. That’s why I’m a big fan of DIY – it’s mostly because I don’t trust people to do the job right.

Many years ago, I had a 2002 Camaro SS with an aftermarket 12-bolt axle, and that sumbitch whined like a banshee from the moment it rolled out of my garage with that 12-bolt installed. The gear whine completely ruined the driving experience, but I didn’t have the tools, time, or confidence to try to rebuild it myself, and I certainly didn’t know who I could trust to do the job to my satisfaction. I sold that car shortly after I bought my Viper, but I always regretted not getting that fixed, or at least trying to do it myself.

That ends now.

It’s going to take me a while to put together all of my thoughts and pictures into a somewhat coherent story, so please be patient, and I’ll keep adding to this write-up as I have time. The information that follows applies to any Gen 3/4/5 Viper (2003-2017) differential, and most of it should also apply to the Gen I/II cars, so hopefully someone will find this helpful, especially as parts supplies continue to dry up and members move on to other platforms (and take their knowledge with them).

Results 1 to 25 of 46

Thread: Viper Dana Super 44 Rebuild

Hybrid View

-

09-16-2022 #1Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

Viper Dana Super 44 Rebuild

-

09-16-2022 #2Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

Disclaimer and Warning

Disclaimer

Let’s get this out of the way: I’m not a mechanic. I have no formal training when it comes to working on cars. Full stop.

I have been turning wrenches for ~20 years, and I’ve done many projects on all of my vehicles, including this one. Most of them I’d say have even been successful. But I’m not an expert, and I’ll gladly defer to anyone that is. If you see something that doesn’t seem right, feel free to ask, or just point it out. But I’d also ask that you offer an explanation instead of just criticism – that’s the only way we’re all going to learn and grow stronger as a community.

I will say, though, that I did consult with someone that has rebuilt many differentials (mostly Toyota products), and still does. He was kind enough to offer his wisdom and advice, all of which I’ll pass along to you when and where appropriate. I can’t say enough kind words about the gentleman who helped me – it was truly a blessing.

Warning

This is a hugely time and resource intensive project. I lost count of the number of hours I spent swapping shims, painting gear teeth, reading patterns, and taking it all apart only to do it over again. And over. And over. This is a repetitive process, no two ways about it.

I also spent a small fortune in tools and specialty equipment, most of which I will likely never use again (except for maybe another differential rebuild). I’ll list what I bought, why I bought it, and where I think your hard-earned dollars are best spent.

The good news: this is not a difficult task, but it is a game where thousandths of an inch (like 0.001-0.002”) matter. And I have examples (with pictures) to back that up.

Still interested? Let’s dive in.

-

09-17-2022 #3Enthusiast

- Join Date

- Oct 2014

- Location

- The Netherlands

- Posts

- 182

Yes very interested.

-

09-17-2022 #4Enthusiast

- Join Date

- Jul 2014

- Location

- Bulverde, Texas

- Posts

- 769

I'm looking forward to seeing this develop as I've always considered swapping gears for 3:55s and have been apprehensive to let someone else do it for the reasons you cited. Good luck, Steve and thank you for sharing.

*just started following on Instagram too.Last edited by SA Heat; 09-17-2022 at 01:07 PM.

-

09-17-2022 #5Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

Basic Information

Viper Differential Information

The 2003-2017 (Gen 3, 4, & 5) Dodge Vipers use the same basic design for the rear differential. The design is based on a Dana Super 44 differential, also known as a Dana 44HD, and sometimes (but rarely) known as a Dana 226.

What it is NOT is a standard Dana 44.

What’s the difference? The Dana Super 44 uses a larger diameter ring gear – 8.9” for the Super 44 vs. 8.5” for the standard Dana 44. As an aside, 8.9” converted to millimeters is 226 mm, hence the Dana 226 designation. The Super 44 ring gear is held to the carrier with ten (10) 7/16”-20 (fine thread) bolts, and are Grade 9 (very high strength). The Super 44 also uses a larger pinion gear with more splines at the pinion gear to yoke interface – 29 splines (1.626” pinion shaft diameter) for the Super 44 vs. 26 splines (1.375” pinion shaft diameter) for the standard Dana 44. The Super 44 bearings are also larger to handle heavier loads.

Bottom line: the Viper differential is a beefed-up Dana 44, so don’t go ordering parts for a standard Dana 44 (which was used in many vehicles, including Jeeps) hoping they will work in a Viper.

There are some minor differences by model year across the generations, but for the most part, the differential housings can be swapped from one generation to another (within Gen 3, 4, & 5 Vipers) without issue as the external mounting points are the same. The major differences are with the internals, specifically the limited slip units and ring and pinion gear ratios. Here’s the quick and dirty version:

Gen 3 (2003-2006) = Hydra-Lok Limited Slip w/ 3.07 ring and pinion gear ratio

Gen 4 (2008-2010) = GKN Visco-Lok Limited Slip w/ 3.07 ring and pinion gear ratio

Gen 5 (2013-2017) = GKN Visco-Lok Limited Slip w/ 3.55 ring and pinion gear ratio

It should be noted that the Gen 5 ACRs came with a finned rear cover for better passive cooling, but all else appears to be the same. The ACR differential cover can be used on Gen 3, 4, and non-ACR Gen 5 Vipers.

There are differences among the generations with the stub axles (the small splined shafts that come out of either side of the differential and attach to the axles), and the axles themselves. I covered all of this in detail with pictures in this post: https://driveviper.com/forums/thread...l=1#post433200

Backwards compatibility goes something like this:

Axles:

Gen 3 and Gen 4 axles are interchangeable

Gen 3 and Gen 4 axles can be used with either Gen 3 or Gen 4 stub axles

Gen 5 axles can only be used with Gen 5 stub axles

Stub Axles:

Gen 3 stub axles cannot be used with the Gen 4/5 GKN Visco Lok differential due to the location of the internal retention ring grooves

Gen 4 stub axles can be used in a Gen 5, but you would have to use Gen 3/4 style axles

Gen 5 stub axles can be used in a Gen 4, but you have to use the Gen 5 axles

Note: most aftermarket differentials are not compatible with the OEM stub axles, and will come with their own stubs (I’ll address this later on when I get to what parts I installed).

For those that don’t understand ring and pinion gear ratios, I’ll offer the following (very basic) explanation.

The purpose of a ring and pinion is two-fold:

- Direct the power from the engine/transmission/driveshaft to the driven wheels by turning it 90°

- Act as a torque multiplier to get the car moving and keep it moving

The torque multiplication part is where the gear ratio comes into play. The pinion gear (the smaller one with the long shaft) and the ring gear (sometimes referred to as a crown gear) have a set number of teeth. The number of teeth is what gives you the gear ratio (after doing a little math). For the Gen 3/4/5 Vipers, the most common ones are:

- 43 teeth ring gear, 14 teeth pinion gear; 43 divided by 14 is 3.0714 (a.k.a. 3.07 gears)

- 39 teeth ring gear, 11 teeth pinion gear; 39 divided by 11 is 3.5454 (a.k.a. 3.55 gears)

- 41 teeth ring gear, 11 teeth pinion gear; 41 divided by 11 is 3.7272 (a.k.a. 3.73 gears)

- 43 teeth ring gear, 11 teeth pinion gear; 43 divided by 11 is 3.9090 (a.k.a. 3.91 gears)

For 3.07 gears, the pinion gear will turn approximately 3.07 times for each 1 time the ring gear turns. The gear ratio is how much the torque gets multiplied after going through the differential. Hopefully it is easy to see that a 3.91 gear ratio will provide more torque multiplication to the tires than a 3.07 gear ratio, but there are always pros/cons. As an example, for a given speed, say 70 MPH, the engine will operate at lower RPMs with 3.07s than it does with 3.91s. The benefit is that the 3.07s will run a bit cooler. The downside is that it can really bog the engine down, but that’s why they make a transmission with many gears to overcome that minor annoyance.

I chose to stay with Dana Spicer gears since they were/are an OEM supplier. Here are the part numbers for the gear ratios listed above:

3.07: 43/14 (ring/pinion); Dana Spicer part number 80739-5 (set) – Mopar part number 5093384AA

3.55: 39/11 (ring/pinion); Dana Spicer part number 84073-5 (set) – Mopar part number 68203459AA

3.73: 41/11 (ring/pinion); Dana Spicer part number 84212-5 (set)

3.91: 43/11 (ring/pinion); Dana Spicer part number 84213-5 (set)

When ordering gears, especially other brands, you need to make sure the ring gear diameter is correct (8.9"), and the pinion spline count and diameter are correct (29 splines, 1.626" diameter). If the company doesn't provide that information, call and ask - otherwise, you might end up with standard Dana 44 gears that won't work.

Important note: ring and pinion gears come as a matched set. You cannot mix and match ring and pinion gears, even if they are the same gear ratio from the same manufacturer. All ring and pinion sets come etched with matching identification numbers to keep them from getting mixed up. If you don’t see unique numbers/symbols etched on both gears, or if they don’t match, don’t go any further until you figure out what’s going on.

Here are a couple of good online references I found that may be useful to others:

https://www.pirate4x4.com/d1/tech/bi...ice_manual.pdf

https://d3qx1uccksbb2n.cloudfront.net/docs/XGI.pdf (see page 94)Last edited by Steve M; 09-17-2022 at 09:42 PM.

-

09-18-2022 #6Enthusiast

- Join Date

- Aug 2021

- Location

- South Florida

- Posts

- 13

Thanks for creating this thread and started following you on Instagram. I’ve worked in shops throughout college and never really tackled rear end swaps more than a couple times. No space for error on aligning gears. With the original gears in my gen 3 I’m living on borrowed time ������

-

09-18-2022 #7Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

Parts

Viper Differential Rebuild Parts

Below is a list of the parts I ordered/received for this rebuild. Most of these supplies came from Jon B, and some I sourced myself (I’ll note those when/where applicable). I’m sure I’ll forget something, so if it looks like something is missing, please ask.

First, a picture:

The details:

- Dana Spicer 3.73s: the gear ratio choice was a personal one, with a focus on drag racing. These might be a bit much for the street, but to be frank, so are the current 3.55s that I’ve been running, at least when it comes to traction in first and second gear.

- OS Giken Differential/Carrier (optional): I originally wanted a Wavetrac, but there weren’t any available when I was ordering parts. Jon B had an OS Giken sitting on the shelf, so after some thought, I went ahead and had him send it my way. This is not a cheap unit, but I know it has a very good reputation, and should be plenty stout for drag racing. I’ll make another post about this later.

- OS Giken-Specific Stub Axles (optional): as already stated in the post above, most aftermarket differentials require different stub axles. This is part of the reason why differentials can be so expensive. The OS Giken came with its own stub axles, so your old ones will not be reused.

- Nitro Gear Solid Pinion Spacer (optional): the differential rebuild kit that Jon provided came with a standard crush sleeve (pictured above). I’ll make another post about why I chose to do a solid pinion bearing spacer instead.

- Pinion Bearing Shims: the rebuild kit came with 8 different pinion bearing shims, which go under the inner pinion bearing and set the pinion depth. It included the following sizes (all measurements in inches): 0.040, 0.042, 0.045, 0.046, 0.0485, 0.050, 0.0525, 0.054. This assortment was sufficient to get me started, but I ended up ordering some additional shims once I started zeroing in on the proper gear mesh (more about this later).

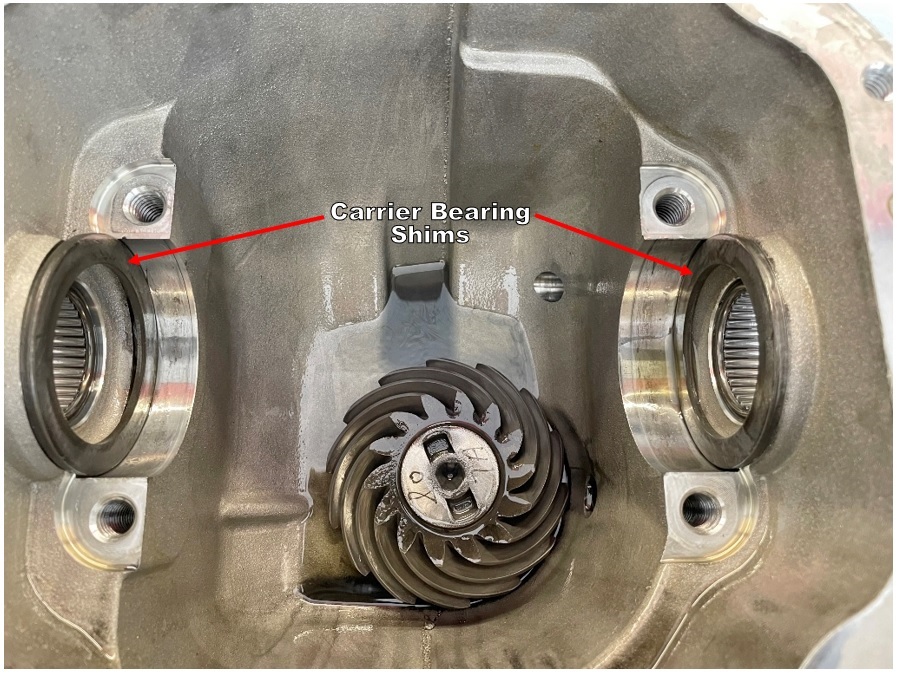

- Carrier Bearing Shims: the rebuild kit came with 5 different carrier bearing shims, which go on either side of the carrier bearings in the differential case and set the backlash (this will all be shown later). It included the following sizes (all measurements in inches): 0.126, 0.129, 0.1315, 0.1345, 0.1375. Again, this was sufficient to get me started, but I ended up ordering additional carrier shims once I started getting close on the setup (more about this later).

- Pinion Bearings: Jon B’s rebuild kit included new Koyo pinion bearings. I have nothing against Koyo bearings, but I prefer US-made Timken bearings when I can get them. I’ll make a separate post about bearings, sizes, and part numbers later.

- Carrier Bearings: the rebuild kit included new Timken (US-made) carrier bearings.

- New Pinion Seal: you’ll end up destroying the original pinion seal during disassembly, so a new one is required. It will not be installed until final assembly.

- New Stub Axle Seals: these don’t necessarily have to be replaced unless you have some leaks, but it is never a bad idea to go with new ones. These can really be installed at any time, but probably best left until final assembly to prevent damage during setup trial/error.

- New Ring Gear Bolts: ring gear bolts are not reusable, so don’t even try. You’ve come this far, so why cut corners now? The rebuild kit came with 10 new 7/16”-20 Grade 9 bolts.

- New Pinion Nut and Washer: again, these should never be reused. The pinion nut is a one-time use type of item – it is a prevailing torque design (some of the threads are slightly deformed to keep it from backing off). You’ll want to source a non-locking pinion nut for setup – more about this later.

- New U-Joint Strap Hardware: the bolts and straps the hold the driveshaft to the pinion yoke should never be reused. The rebuild kit came with new hardware, Spicer part number 3-70-48x.

- Permatex Ultra-Grey RTV: this was provided in the rebuild kit, and is what you'll use to seal the differential cover to the housing. This particular variant is specified for high vibration, high torque applications, which seems fitting for a differential.

And here is a list of parts that you’ll reuse:

- Oil Slinger

- Pinion Yoke

- Carrier Bearing Caps

- Carrier Bearing Cap Bolts

- Differential Cover Bolts

- Stub Axle Support Bearings (these are the needle roller bearings pressed into the sides of the case – more about these later)

You can also technically reuse any shims that come out of your existing differential, provided they are in good shape. Mine were, but I didn’t end up reusing any of them.

It should also be noted that no gear oil was provided. The type of gear oil you’ll end up using depends on the differential you choose, and you’ll need 3-4 quarts of it (to cover the initial fill + the oil change you’ll need to do after break-in). The OS Giken has very specific requirements, and the OEM fill does not meet those requirements. Again, more about this later.Last edited by Steve M; 09-18-2022 at 10:56 AM.

-

09-24-2022 #8Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

Bearings

Viper Differential Bearings

There are 6 total bearings in the Viper’s differential that can be serviced – you’ll only be dealing with 4 of them.

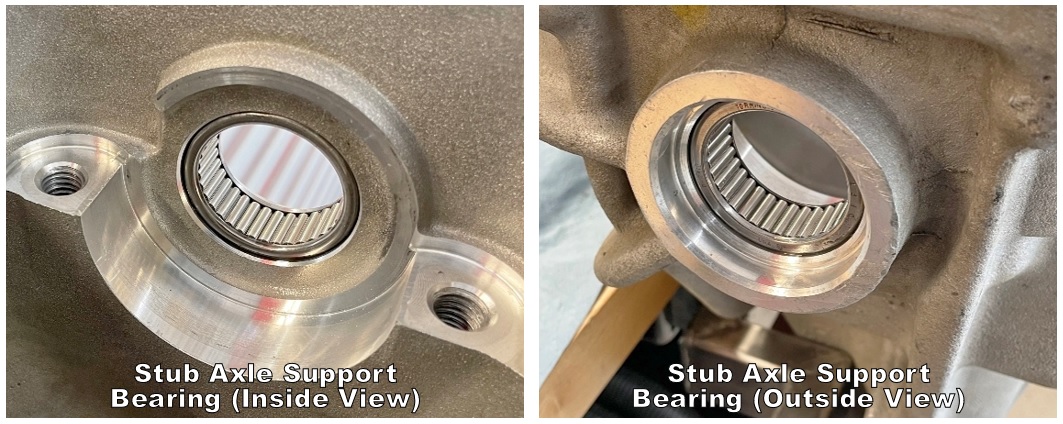

The 2 you will (likely) not be dealing with are the stub axle support bearings that are pressed into the sides of the case where the stub axles enter (they sit just behind the stub axle seals). They are needle roller bearings, and look like this:

These are not highly stressed, so as long as they look like they’re in good shape (mine were), you’ll just leave them where they are. Mine were Torrington brand bearings, part number B2412.

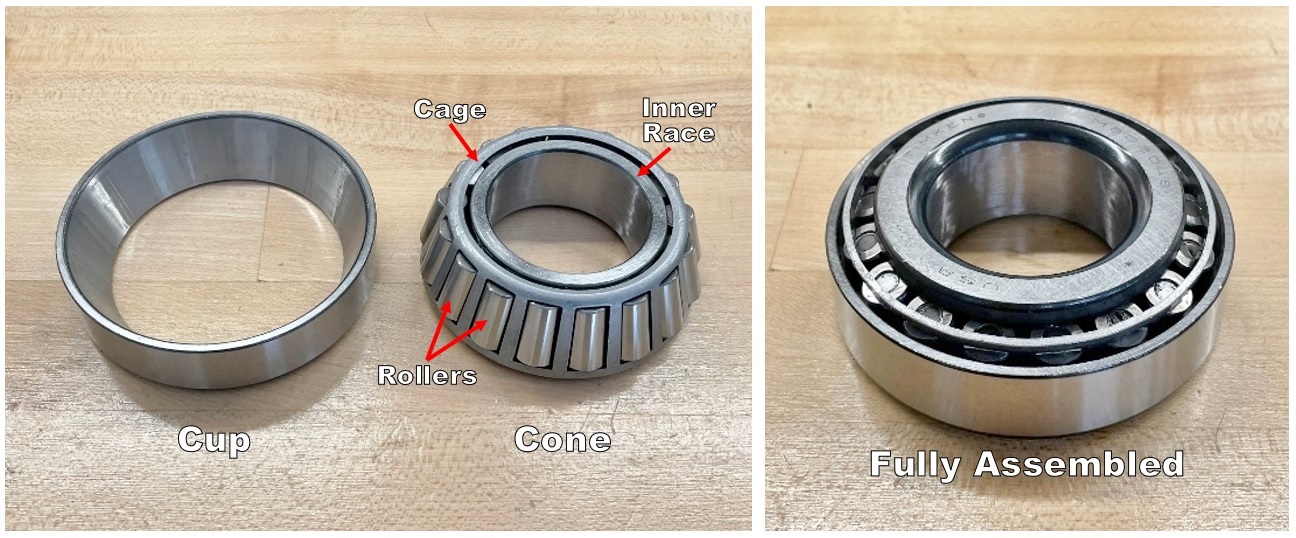

The 4 other bearings you will be replacing are the pair of carrier bearings that go on either side of the carrier, and the inner (larger) and outer (smaller) pinion bearings. The carrier and pinion bearings are tapered roller bearings, and come as a two-piece set. The inner piece is called the cone, and the outer piece is called the cup. The cone consists of multiple parts, including the inner race, the rollers (which ride on the tapered portion of the inner race), and the cage (which holds the rollers in place). The cup is a single piece, and provides the other tapered surface against which the rollers ride. A picture is probably worth more than what I just wrote:

And another picture to give you an idea of the size differences among the inner and outer pinion bearings, and the carrier bearings:

Two important notes on these:

1. Tapered roller bearings can be ordered as separate pieces (e.g. you can order only the cup, or only the cone). If you want the full bearing, you need to make sure you order a set that includes both halves.

2. You should not combine cups/cones from different manufacturers. This is specifically stated in the Dana Spicer light axle service manual referenced in one of my posts above (https://www.pirate4x4.com/d1/tech/bi...ice_manual.pdf), pg. 9.

To expand on the second point, take a look at the following picture that shows the cone assemblies from two different manufacturers (Timken and Koyo), both with the same part number:

Both are replacements for the inner pinion bearing (the larger of the two on the pinion). The Timken bearing (left) uses fewer rollers than the Koyo bearing (right) – 17 rollers for Timken, 18 rollers for Koyo. The Timken inner race, against which the crush sleeve/solid spacer rides, is substantially beefier than what is used on the Koyo. I can’t quantify that one design is better than the other; they are just different. Even though they are not pictured, there are also subtle differences between the cups - the angles are slightly different between the two brands. In a game where thousandths of an inch matter, mixing and matching cups and cones from different manufacturers is not something you should consider doing, especially when new bearings are relatively cheap compared to the other parts of this build.

Tapered roller bearings require a certain amount of preload to ensure a long service life. Basically, the cup and cone assembly need pressure applied so that the rollers have good surface area contact with both the inner race and the cup (sometimes referred to as the outer race). Too little preload, and the rollers will develop hot spots from too little surface contact area. Too much preload will also generate too much heat. Too much heat will affect the heat treatment of the bearings – if that gets messed up, the bearings will destroy themselves.

The pinion bearing preload is set with either a crush sleeve or a solid pinion bearing spacer (more about that in the next post). The carrier bearing preload is set with the carrier shims that go between the carrier bearing cups and the differential case. I’ll talk about this again when I get into the final assembly stage.

Here are the part numbers for the carrier and pinion bearings:

Carrier Bearings (two sets required):

Cup: LM603012

Cone: LM603049

Set: Timken Set 36 (includes one cup and one cone with the part numbers listed above)

Inner (Larger) Pinion Bearing (one set required):

Cup: M802011

Cone: M802048

Set: Timken Set 328 (includes one cup and one cone with the part numbers listed above)

Outer (Smaller) Pinion Bearing (one set required):

Cup: M88010

Cone: M88048

Set: Timken Set 63 (includes one cup and one cone with the part numbers listed above)

Prices are all over the place, so shop around if you are going to piece together a rebuild kit yourself.

Set-up Bearings

Several companies offer “set-up bearings” – basically, these bearings have a modified inner race that can be slipped on and off without the need for a press. This allows you to easily change out shims that sit under a pressed-on bearing.

Pros: set-up bearings save you a lot of time when trying to zero in on the right shims. Every time you change the pinion depth, you have to change the shim under the bearing, and you’ll be doing this multiple times to get the gear mesh just right. If you have to press a bearing on and off each time you want to change the shim, you can see how this would add up.

Cons: as I found out, there may be slight differences with your setup once you press on the final bearings. I’ll show you why this ended up being an issue for me later, and why I think it happened.

Bottom line: if you are going to use a set-up bearing, do not pay the ridiculous prices I saw (like $100+ for a single bearing) – you can make one yourself.

For the Viper Dana Super 44, only one setup bearing is required: the inner (larger) pinion bearing (part number M802048, cone only). This is the only bearing that gets pressed on that has a shim underneath. The carrier bearing shims go on the outside of the bearing assembly, so set-up bearings for these would make no sense for this particular application. The outer (smaller) pinion bearing is an interference fit, and can be removed with a few taps of a hammer.

As a reminder, if you are going to make a set-up bearing for the inner pinion bearing, make sure it is the exact same brand as the one you'll be using for your final setup.

I’ve seen all sorts of methods for making your own set-up bearings, including using a die grinder or a flap wheel in a drill. I agonized over buying a die grinder or flap wheels for this purpose, but if you already have a Dremel, you don’t need any of that. All you need is an 80-grit sanding drum (a.k.a. sanding band), like this: https://www.dremel.com/us/en/p/445-26150445aa, and a little bit of patience. About a minute of taking one of those to the inner race removed enough material to allow the inner pinion bearing to slide on easily.Last edited by Steve M; 09-24-2022 at 07:49 PM.

-

09-25-2022 #9Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

To crush or not to crush

Crush Sleeve vs. Solid Spacer

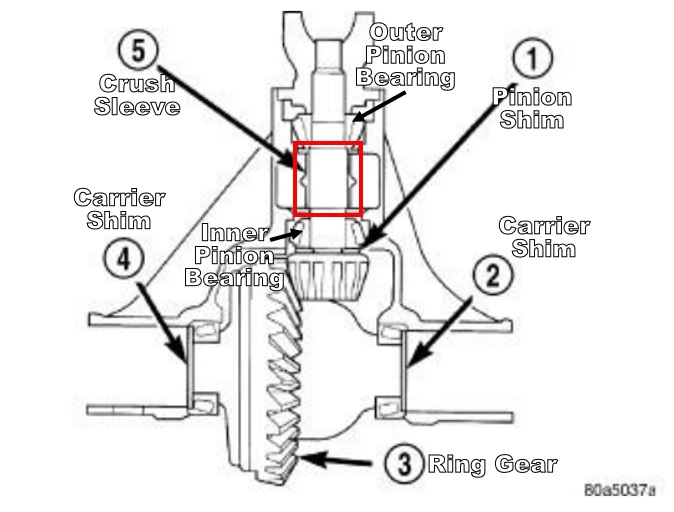

The pinion gear has two tapered roller bearings (outer and inner) that oppose each other, holding the pinion gear stationary in the differential housing (front-to-back and side-to-side) while still allowing it to rotate. As stated above, tapered roller bearings require a certain amount of preload to prolong their service life. That preload is established with a spacer located between the two pinion bearings, seated on the inner races of each bearing. This spacer is shown as #5 in the diagram below from the service manual:

There are two design options for spacers – the standard crush sleeve, and a solid pinion spacer. The OEM Viper solution was a crush sleeve, and there’s a good reason for that when looking at it from a production standpoint.

Bearings and differential housings are all going to have varying tolerances from unit to unit in a mass production environment, so the amount of space between the inner races needed to establish the correct bearing preload, measured in inch-pounds of torque required to rotate the pinion gear, is also going to vary from one differential to the next. You could theoretically machine a spacer that is unique to each differential housing and set of bearings, but that would require thousands of different part numbers, and would be a nightmare from a serviceability standpoint since that same spacer would likely not work with a new set of bearings required for a rebuild.

That’s the beauty of a crush sleeve – it is made slightly longer than what is needed to establish the correct amount of preload, but is designed to crush under a load. That load is applied by tightening the pinion nut – during assembly, you keep tightening the pinion nut and measuring the pinion torque-to-rotate until you reach the desired preload. Now you have one part number, and you theoretically only need to assemble everything once, assuming you don’t overtighten the pinion nut (which would over crush the sleeve). That’s the downside of the crush sleeve – it is a one-time use item, so if you mess up the assembly process by overtightening, you have to take it all back apart, install a new crush sleeve, and try again.

The other option is a solid pinion spacer. This sleeve is made from a substantially thicker tube of steel, and comes with a set of shims that you mix and match to achieve the correct amount of preload. But therein lies the downside – during the assembly process, it is yet another iterative step of putting it together, measuring the preload, and taking it back apart and trying another stack of shims if you don’t get it right on the first try (and you probably won’t). The solid sleeve is also more expensive, but that is theoretically offset by being reusable.

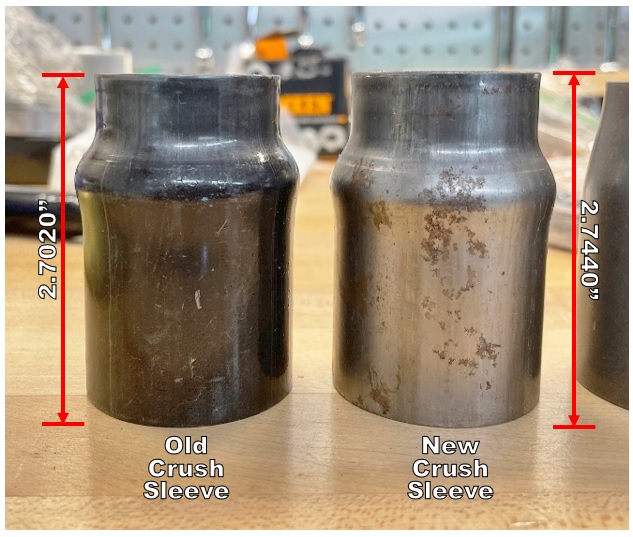

Again, a picture probably tells the story a little better when it comes to the differences between the two designs:

It’s pretty clear how much beefier the solid sleeve is compared to the crush sleeve. And for reference, below is what the solid spacer shims look like:

My solid spacer/sleeve came with 5 different shims of varying thicknesses: 0.010”, 0.012”, 0.013”, 0.016”, and 0.020”. They are super thin, and as I found out later, it is another part of the assembly process where single-digit thousandths of an inch matter.

To give you an idea of how much a crush sleeve needs to be compressed to achieve the correct amount of preload, consider the following picture:

The difference between the two is only 0.042”, but that doesn’t mean much because I don’t know how long the original crush sleeve was. Regardless, it ain’t much.

So why would you pick one over the other?

That’s where the internet seems to be divided. Theoretically, the solid spacer should never deform under heavy loading due to its increased thickness, and thus would be the more reliable choice for heavy duty applications. There are many others out there that say the same for a crush sleeve – it should also never deform due to where it sits in the assembly.

I don’t have a good answer either way. I do know for a fact that the entire differential is subject to some pretty severe shock loading, especially if you encounter wheel hop. The aluminum case can certainly deform, but how much it does under shock loading is unknown. When do I encounter wheel hop? Pretty much every time I do a burnout at the drag strip. Is it enough to deform a crush sleeve and/or distort the housing? No clue.

But I guess I’ll find out. If this differential fails, I’ll just tear it apart and see what happened. I liked the idea of a beefier part for a pretty critical component of the assembly, but I wish I had some concrete numbers to back up my gut.

If you decide to go with a solid pinion spacer like I did, only one company makes them that I found: Nitro Gear & Axle. Link: https://www.nitro-gear.com/SKCSD44HD-p/skcsd44hd.htm

Many other companies distribute Nitro solid spacers, so if Nitro doesn’t have one in stock, you might be able to find one by asking around.

The solid spacer will run you about $60. For reference, a new crush sleeve is about $15, and as already mentioned above, the differential rebuild kit includes a new sleeve.

The choice is yours. I will likely never have enough data points to say which design is the better choice. Your intended use and budget will probably matter the most.Last edited by Steve M; 09-25-2022 at 02:24 PM.

-

09-25-2022 #10Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

Shimmy Shimmy Ya

Shims

I ended up having to deal with 3 different sizes/types of shims during this rebuild: solid pinion spacer shims (not required if using a crush sleeve), pinion shims, and carrier shims. It’s pretty easy to tell each one apart:

To reiterate, the purpose of each shim is as follows:

1. Solid pinion spacer shims (only required if using a solid pinion spacer): these set the pinion bearing preload, which is done during final assembly.

2. Pinion shims: these set the pinion depth (i.e. where the pinion gear sits on the ring gear in reference to the ring gear/axle centerline). Thicker shims push the pinion deeper on the ring gear; this will also reduce backlash (but is not how backlash is set). Thinner shims pull the pinion gear out from the ring gear; this will increase backlash.

3. Carrier shims: these set the backlash (i.e. how much play there is between the ring and pinion gears) AND set the carrier bearing preload.

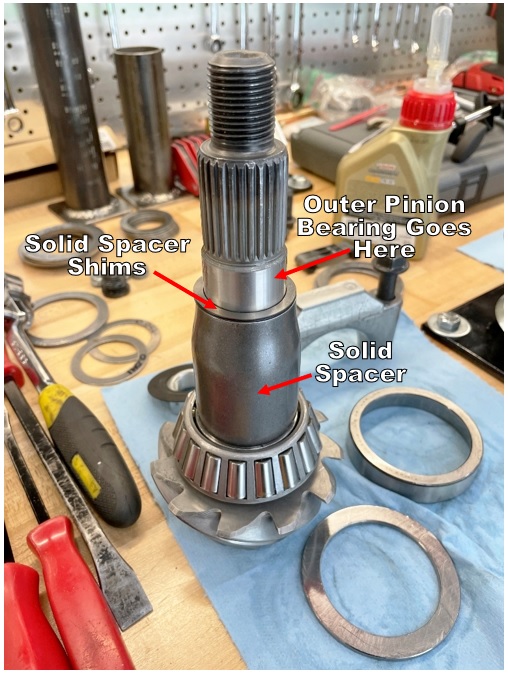

The solid pinion spacer shims sit between the spacer and the outer pinion bearing, and make contact with the outer pinion bearing inner race (part of the cone assembly). Picture for reference:

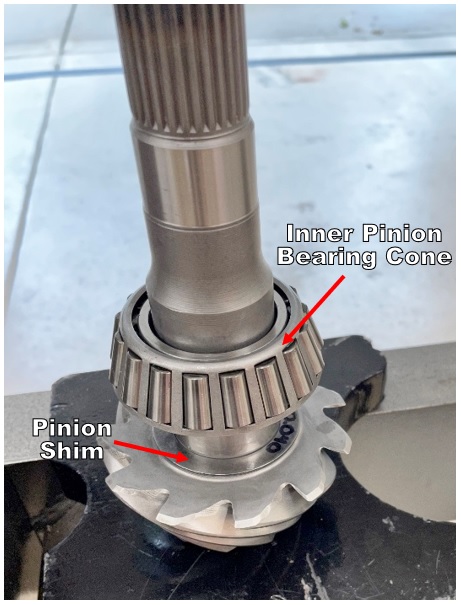

The pinion shim sits under the inner pinion bearing cone, which is pressed on to the pinion gear:

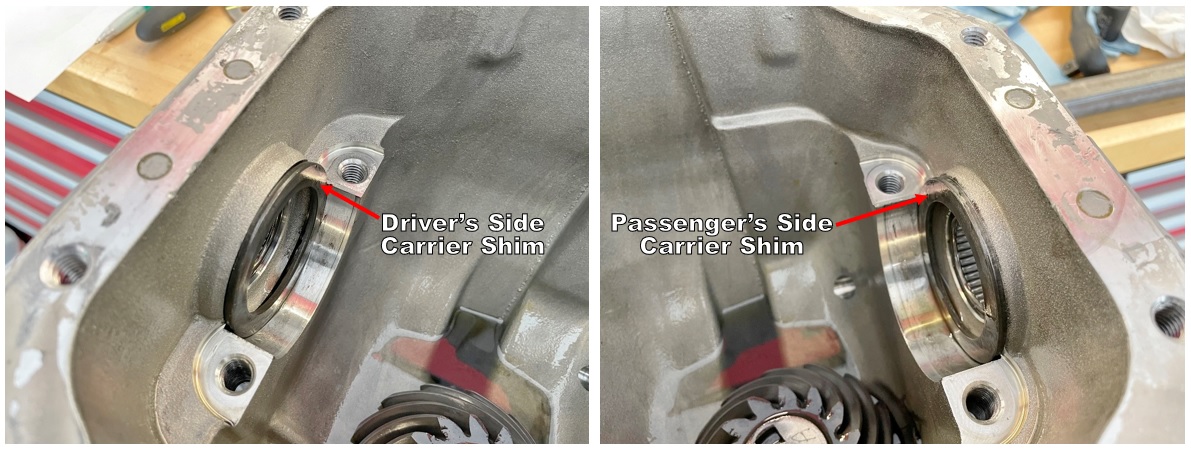

The carrier shims sit between the cup of the carrier bearings and the aluminum case:

Tip: measure the shim thicknesses with a micrometer. Digital calipers also work, but my micrometer was more accurate/repeatable. Write the measurements on each with a black marker for easy reference.

As was already stated, the differential rebuild kit came with 8 pinion shims and 5 carrier shims, all of varying thickness. The Nitro solid pinion spacer came with 5 shims as well. The outer/inner diameter measurements for each type of shim are listed below:

1. Nitro Solid Pinion Spacer Shims: I.D. = 1.327”; O.D. = 1.6470”

2. Pinion Shims: I.D. = 1.646”; O.D. = 2.25”

3. Carrier Shims: I.D. = 2.25”; O.D. = 3”

You can order individual pinion shims from Chrysler/Dodge. They also offer sets of 5 shims over a set range thicknesses. Part numbers below (reference: https://roeracing.com/wp-content/upl...08_Viper.pdf):

0.035” Pinion Shim: 68014932AA

0.036” Pinion Shim: 68014933AA

0.037” Pinion Shim: 68014934AA

0.038” Pinion Shim: 68014935AA

0.039” Pinion Shim: 68014936AA

0.040” Pinion Shim: 05017332AA

0.041” Pinion Shim: 05017333AA

0.042” Pinion Shim: 05017334AA

0.043” Pinion Shim: 05017335AA

0.044” Pinion Shim: 05017336AA

0.045” Pinion Shim: 05017337AA

0.046” Pinion Shim: 05017338AA

0.047” Pinion Shim: 05017339AA

0.048” Pinion Shim: 05017340AA

0.049” Pinion Shim: 05017341AA

0.050” Pinion Shim: 05017342AA

0.051” Pinion Shim: 05017343AA

0.052” Pinion Shim: 05017344AA

0.053” Pinion Shim: 05017345AA

0.054” Pinion Shim: 05017346AA

0.035” – 0.039” Pinion Shim Kit: 04856368

0.040” – 0.044” Pinion Shim Kit: 04856369

0.045” – 0.049” Pinion Shim Kit: 04856370

0.050” – 0.054” Pinion Shim Kit: 04856371

When I started zeroing in on my final pinion depth, I ordered the 0.040” – 0.044” pinion shim kit. As it turned out, I didn’t need it - the differential rebuild kit already had the correct thickness shim. That was very likely a lucky coincidence.

As for carrier shims, those are a bit easier to source outside of the Mopar parts supply chain. Yukon makes a carrier shim kit for the Dana 44HD that covers a wide range of shim thicknesses, part number SK 702005, available here: https://www.amazon.com/gp/product/B0...e?ie=UTF8&th=1

That kit included 12 different shims, a handful of which were in the range I needed for my rebuild.

-

09-25-2022 #11Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

Tools

Below is a list of tools that are either optional, recommended, highly recommended, or required for this task (based on my personal experience). This won’t be absolutely everything, but it should include the bulk of things that some folks may not have in their tool box. These are in no particular order.

Tools I Bought (or already had)

- Calipers: a good set of digital calipers come in very handy for many projects, especially this one.

Recommendation: https://www.mitutoyo.com/products/sm...matic-caliper/

Verdict: Highly Recommended. You can probably get by with cheaper calipers than the ones linked above.

- Micrometer: as mentioned above, I was able to get more precise, more consistent measurements of shims with a micrometer.

Recommendation: https://www.mitutoyo.com/products/sm...of-micrometer/

Verdict: Required. Again, you can probably get by with a cheaper micrometer.

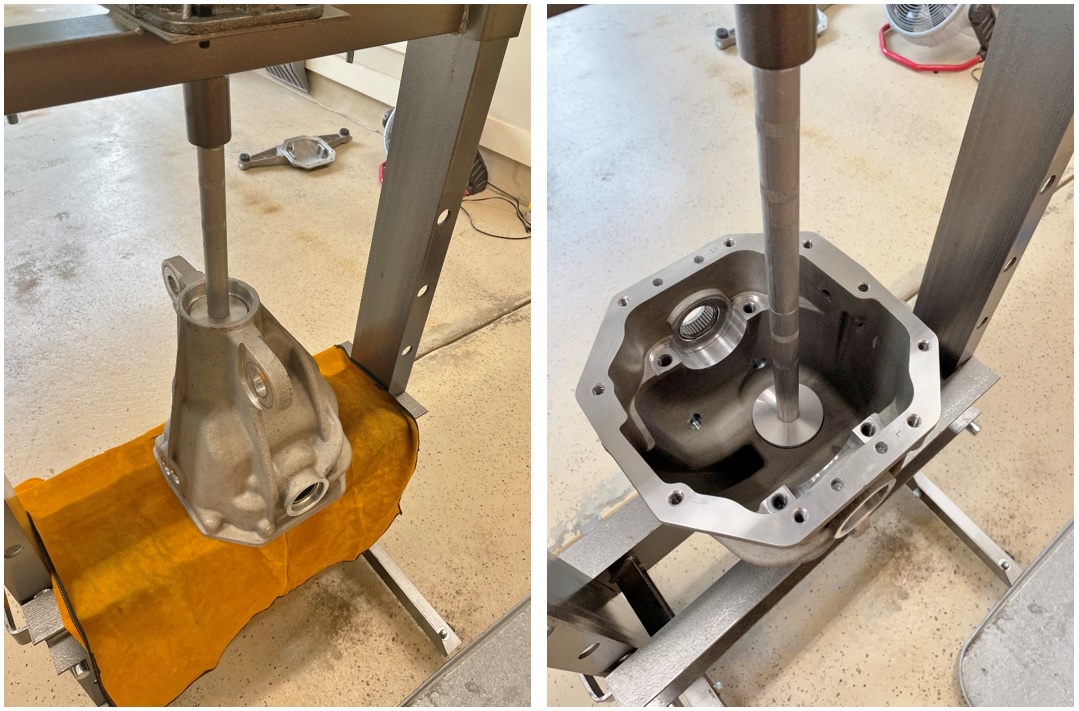

- Hydraulic Press: you’ll need a floor standing hydraulic press to press on the carrier and inner pinion bearings. I was able to borrow a 20-ton press from a friend, but it was way overkill for this job. A 12-ton press would have been more than sufficient.

Recommendation: https://www.harborfreight.com/12-ton...ess-33497.html

Verdict: Required.

Alternative: the service manual states you can use a bearing hot plate like this: https://www.skf.com/us/products/main...tric-hot-plate. The heat will expand the inner race, allowing it to slide on. These can be quite pricey, so I would not entertain this purchase.

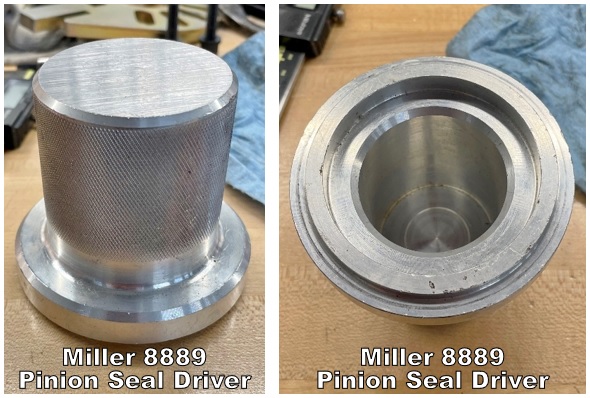

- Seal Drivers: the service manual lists seal drivers for both the pinion and stub axle seals. The pinion seal driver part number is Miller 8889, and the stub axle seal driver is Mopar part number C-4026B. Both can be seen in the pictures below:

Verdict: Recommended. I found a used pinion seal driver on Ebay for $20. The stub axle seal driver was a little harder to come by, and I ended up buying a new one. Both worked great, and provided seal support while also giving you something to bang on, which will keep you from damaging the seals. You’ll see these again later during final assembly.

- Dead Blow Hammer: rebuilding a differential is not a subtle operation. You’re going to be doing some banging, so a BFH will come in handy for many things throughout the process.

Recommendation: https://www.harborfreight.com/hand-t...mer-69004.html

Verdict: Required. I went with the 4-lb version, and I’m glad I did. That it is non-marring is a big bonus.

- Sledge Hammer: see above – there are some things that will need some persuading, like knocking out the old bearing races in the aluminum case.

Recommendation: https://www.harborfreight.com/3-lb-h...q=sledgehammer

Verdict: Required. The 3-lb version was more than sufficient to get the job done.

- 1-5/16” Socket: this was an odd-ball size I didn’t have. It is what you’ll need to remove/reinstall the pinion nut.

Recommendation: https://www.amazon.com/Sunex-242D-2-.../dp/B000GHWO88

Verdict: Required. Sunex makes nice sockets, but there are many different manufacturers out there, so pick your poison.

- Clamshell Bearing Puller: this tool can be used to remove both pinion and carrier bearings without damaging either. If you end up getting this tool, you’ll need an impact (either electric or air powered) to use it. Video showing how it works here:

Recommendation: https://www.amazon.com/gp/product/B01N6SZ742/

Verdict: Highly Recommended. Prices for these things range from $100 all the way up to $500 for the name brand version. The cheap(er) one linked above worked great for me. If you get the tool linked above, you’ll also need a 36mm 6-point impact socket (https://www.amazon.com/TEKTON-6-Poin.../dp/B08DK16GPN)

Alternative: you can also use a hydraulic press and a guillotine-style bearing separator, like this: https://www.harborfreight.com/bearin...ity-63662.html. If you go this route, you may have to modify the separator to fit under the pinion bearing properly.

- 1/2" Impact Wrench (Electric or Air): I can’t tell you how good modern electric impact wrenches are. If you don’t have one, I’d highly recommend getting one. My Milwaukee M18 Fuel 1/2" impact has earned its place in my tool box many times over. This thing will zip the old pinion nut off with a few ugga-duggas without breaking a sweat. I can’t say the same if you try to get it off by hand.

Recommendation: https://www.milwaukeetool.com/Produc...enches/2767-20

Verdict: Highly Recommended. Like really highly recommended.

Alternative: if you choose to remove the old pinion nut by hand, I’d highly recommend investing in a 3/4" breaker bar, like this one: https://www.amazon.com/TEKTON-4-Inch...07H3KJQ83?th=1. My 1/2" breaker bar just wasn’t up to the task.

- Needle or Dial Style Inch-Pounds Torque Wrench: you’ll need one of these to measure the pinion torque to rotate when setting your pinion and carrier bearing preload. The needle style torque wrenches are way cheaper than the dial type, albeit at the expense of accuracy. I cheaped out on this part, but felt like the needle style worked well enough. You only need one that goes from 0-80 in-lbs.

Recommendation: https://www.amazon.com/gp/product/B01FMXEWQC/. These are typically 1/4" drive, so you’ll need an adapter to fit the 1/2" drive 1-5/16” socket listed above. This adapter worked great: https://www.amazon.com/gp/product/B07ZKPCZ65/

Verdict: Required.

- 3/8” Torque Wrench: any aspiring mechanic (shade-tree or otherwise) needs a good 20-100 ft-lbs, 3/8” drive torque wrench. You’ll use this to tighten the carrier bearing cap bolts, the ring gear bolts, and the differential cover bolts.

Recommendation: https://www.amazon.com/Precision-Ins...dp/B000YOX568/. I love split-beam style torque wrenches – they are extremely easy to set, and don’t have to be dialed back to their lowest setting for storage.

Verdict: Required.

- 1/2” Torque Wrench: same as above, just bigger. This covers 50-250 ft-lbs. You’ll use this to tighten the pinion nut. It can also be used for the carrier bearing cap bolts and ring gear bolts, both of which are critical parts, so if you can only afford one, this is the size to get for this job.

Recommendation: https://www.amazon.com/Precision-Ins...02XMSFIM/?th=1.

Verdict: Required.

- Backlash Gauge: you’ll need this to measure backlash and ring gear runout; this will also be used to measure case distortion if you choose to use a case spreader (see below).

Recommendation: https://www.amazon.com/gp/product/B08W235VJW/. I’ll be frank, this thing was cheap Chinese garbage, but it did what I needed it to do. If I was going to do this for a living, I’d get a higher quality unit.

Verdict: Required.

Also Needed: the kit linked above includes a magnetic base to hold everything in place. That’s great and all, except for the fact that the Viper differential case is aluminum. The rod unscrews from the magnetic base, and has M8 x 1.25 metric threads. You can use a hex coupler stand-off nut (https://belmetric.com/steel-coarse-d...u=NLONG8X24YLW) and a 31mm long M8 to M10 stepped stud (https://belmetric.com/m8-to-m10-step...ku=S8X10X31YLW) to make an adapter – those two parts will allow you to screw the rod directly into the M10 x 1.5 tapped holes that accept the differential cover bolts. Problem solved.

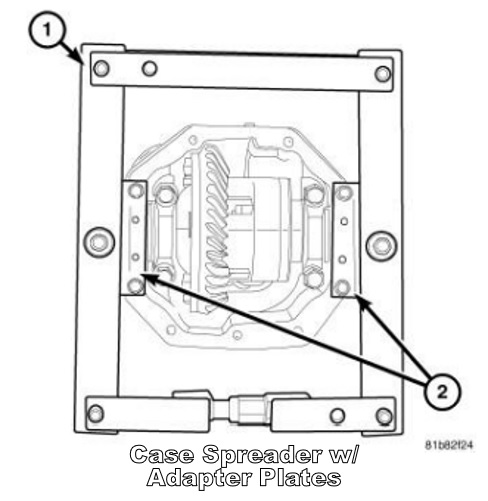

- Case Spreader: this tool is completely optional. As the name indicates, it is used to spread the case apart to make getting the carrier in and out of the case easier. It looks something like this:

The service manual lists the adapter plates as tool number 10033, and the spreader as tool number W-129-B. If you look up the spreader, you’ll see that it is $$$. Bryan (cowger) made his own.

Verdict: Optional. Why is it optional? Because it can be done with other methods that require substantially cheaper tools, and you won’t have to worry about spreading the case too far, which can damage it. Fast forward to 22:04 in this video to see how:

Bottom line: all you need is a 3/4" box end wrench + turning the pinion to get the carrier out, and your 4-lb dead blow hammer to get it back in. Screw getting a $600+ case spreader, or spending hours building one. If you do use a case spreader, the max you can spread it is 0.010” (source: service manual, page 5939).

- Pinion Yoke Holding Tool: you need something to hold the yoke in place while you wrench on the pinion nut.

Recommendation: https://www.amazon.com/gp/product/B07JGJ2LJ6/

Verdict: Required.

Also Needed: you’ll need bolts to attach this to the pinion yoke. You can use the ones that hold the u-joint straps in place, but they won’t give you much thread engagement in the yoke when using the tool linked above since it is 3/8” thick. The yoke threads are M8 x 1.0. I used these 30 mm under head length socket head bolts: https://www.fastenal.com/product/details/35753. They are grade 12.9, so they should hold up to some serious abuse while you are wailing on that pinion nut. Make sure you get some hardened washers to go under the bolts too: https://www.fastenal.com/product/details/11128387

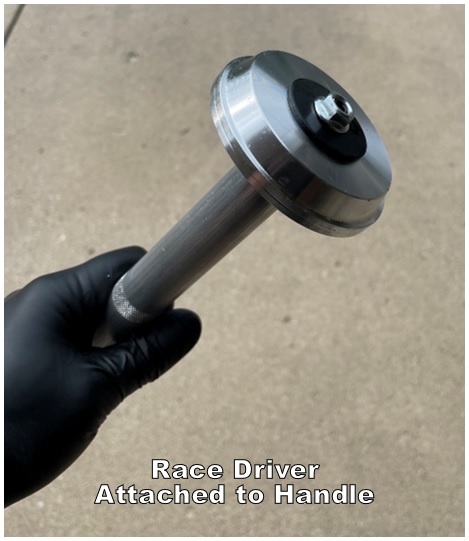

- Bearing Race Driver Set: the pinion bearing cups (outer races) need to be pressed into the differential housing. A bearing race driver is needed to do that without damaging the races.

Recommendation: https://www.tooldiscounter.com/produ...r-set-lis59400

Verdict: Required. The Lisle 59400 set is very nice, and has the exact sizes need for this job. The outer (smaller) pinion bearing cup/race is 2-11/16” (2.6875”), and the inner (larger) pinion bearing cup/race is 3-1/4” (3.25”). If a race driver set doesn’t have these exact sizes (none of the Harbor Freight ones I looked at did), then they won’t work. Bonus: this set also includes a punch with extensions that came in very handy when knocking out the old races.

- Other Tools: 3/4" box end wrench, 3/4" 6-point socket (ring gear bolts), 19 mm 6-point socket (carrier bearing cap bolts), 13 mm 6-point socket (differential cover bolts), various ratchets (3/8” and 1/2" drive), a chisel with a blunt end, adjustable wrenches, metal files (for removing burrs), air compressor (to blow out holes and remove debris), etc. I know I’m forgetting stuff, but there really isn’t anything I can think of that is out of the ordinary for this type of job.

Tools I Made

I made a couple of custom tools that really came in handy for specific tasks. I ended up learning how to weld during this project, and I ended up using those skills to make 3 one-off tools – a breaker bar that worked with the pinion yoke holding tool referenced above, and 2 tools for pressing on the bearings. None of these are specifically required, but I used each many times.

- Breaker Bar: the pinion yoke holding tool has a place that accepts a breaker bar, but it does not come with one. I ordered a 3 foot long piece of mild steel square tubing, 1” x 1” x 0.120” wall thickness. The inside dimensions were good, but there was too much play with the outside, so I ended up building it up by welding on some extra material and grinding it down until it was a nice, tight fit (I added about 0.17” of extra material):

- Bearing Press Adapters: when pressing on bearings, you need some way of only making contact with the inner race to avoid damaging the bearing during the process. As stated above, I made 2 press adapter tools – one for the carrier bearings, and one for the pinion bearings. I used the following supplies for each:

1. Carrier Bearing Press Adapter: 6” long piece of 2" O.D. x 0.095" Wall (1.81" I.D.) Alloy Steel Round Tube 4130 (seamless) welded to a 3” x 3” plate of 3/16” thick Carbon Steel Rectangle Bar 1018, Cold Finish

2. Pinion Bearing Press Adapter: 8” long piece of 2" O.D. x 0.156" Wall (1.688" I.D.) Alloy Steel Round Tube 4130 (seamless) welded to a 3” x 3” plate of 3/16” thick Carbon Steel Rectangle Bar 1018, Cold Finish

They look something like this:

You’ll see both of these again later in action. Oh, and by the way, steel is f-ing expensive, especially when you buy it in small quantities. There are definitely other ways to do this, so if you need some other ideas, just ask. If you do try to recreate these, you need to make absolutely sure that the tubing cuts are perfectly square.

Supplies

Here are some other odds and ends that I used, the first of which is the most important.

- Spare Pinion Nut (non-locking): you need spare nut (or 2) when doing your mock-up assemblies to determine the correct pinion depth. You do not want to use the pinion nut that comes in the rebuild kit; this nut is a prevailing torque type of nut that has a couple of deformed threads, and essentially acts as a lock nut. You’ll be screwing the pinion nut on and taking it off multiple times, and you don’t want to damage either the pinion shaft threads or the nut’s threads by using this style of nut (it is basically a one-time use type of item). The pinion shaft thread size is 7/8”-14 (fine thread), and you’ll want to use a Grade 8 nut for this one, especially if you go with a solid pinion spacer. Something like this: https://www.fastenal.com/product/details/1136468

- WD-40 (I’ll explain why later)

- 800-1000 Grit Sand Paper (goes with the WD-40)

- Brake Cleaner (I went through about 3-4 cans of this stuff)

- Paper Towels (I used ~ 3 rolls of the blue Scott Shop Towel brand)

- Nitrile Gloves (highly recommended – gotta keep those nails clean)

- Gear Paint & Small Paint Brushes (more about this later)

- Gear Oil (to help with assembly)

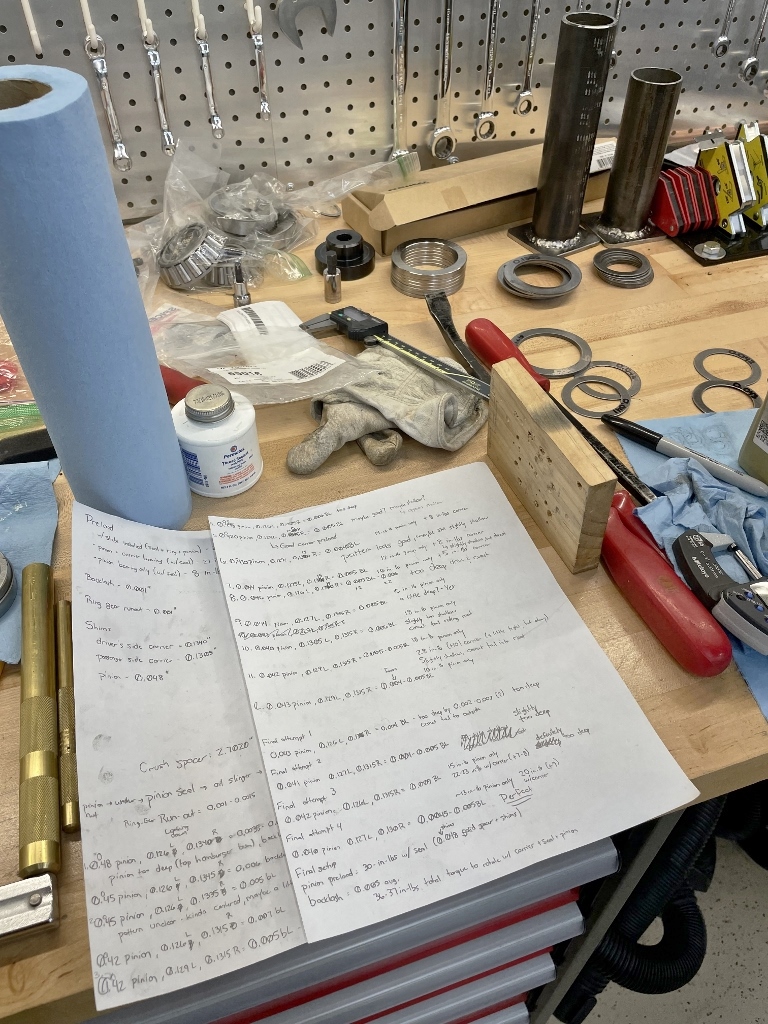

- Pencil & Paper to take notes (yes, you need to take notes)

- Camera (your phone will work)

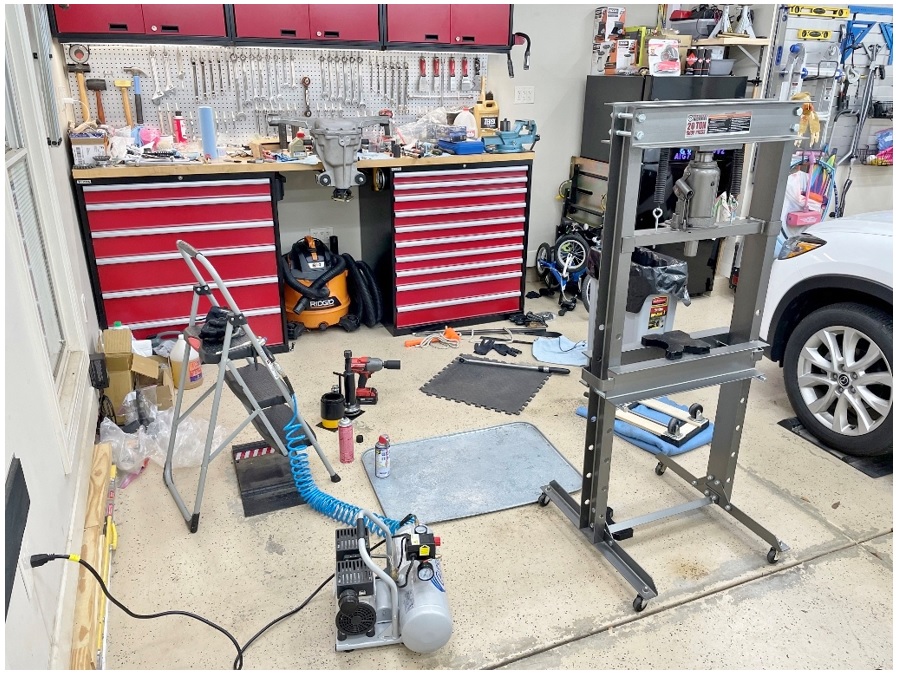

If you have most of the stuff listed above, you’ll be in the ball park. As a bonus shot, here is a picture of what my garage actually looks like when I’m working on a project:

You can see many of the tools I referenced above somewhere in that picture.Last edited by Steve M; 09-25-2022 at 10:34 PM.

-

09-30-2022 #12Enthusiast

- Join Date

- May 2016

- Location

- New York

- Posts

- 477

great read. keep it up!

-

10-01-2022 #13Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

Ill Give You Something To Mount

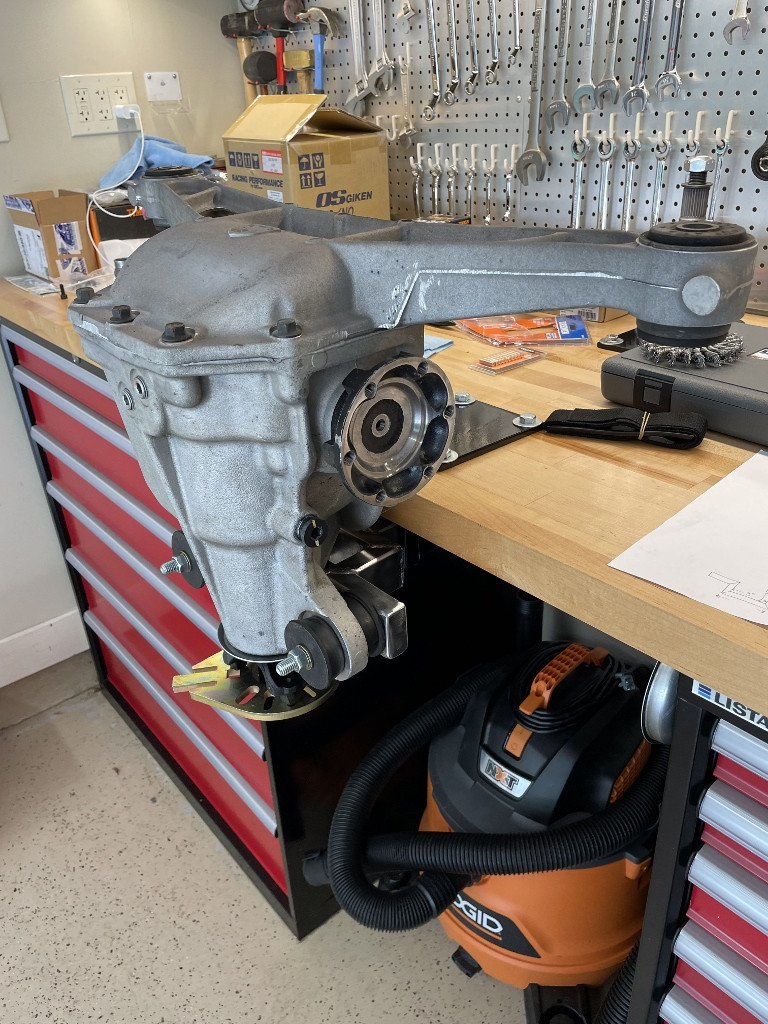

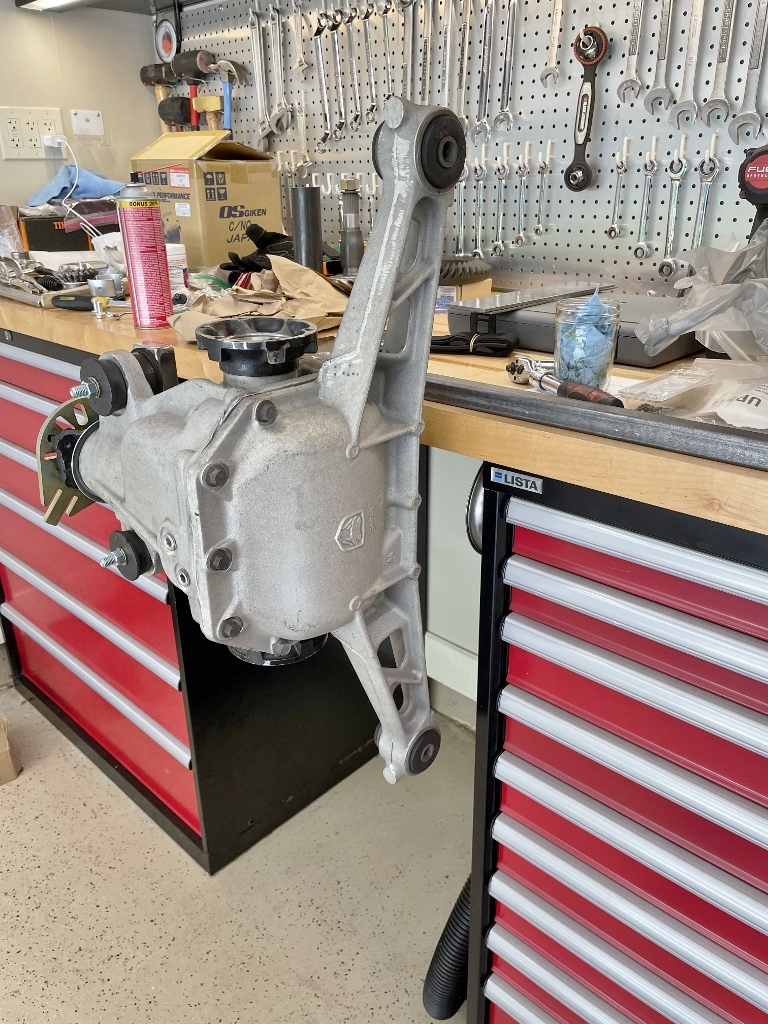

Differential Mounting Fixture

So how in the hell do you hold the differential while you are wrenching (and banging) on it during a gear swap?

I agonized over this question for days on end. Putting it on the floor certainly won’t work, and you sure as hell can’t leave it installed in the car since the frame is in the way.

There are some options out there, but none of them seemed to be a good fit for the Viper’s differential housing. The housing itself with the batwing cover removed is very similar to a third member, where the carrier, ring & pinion, bearings, etc. are contained in a removable center section. This design is used in many Toyota truck rear axles and the popular (at least in racing circles) Ford 9”. There is one key difference, however: most third member center sections use through holes to mate them to the rest of the housing, which would allow you to use a nut + bolt to hold it to a bench mounting fixture. The Viper’s mounting holes are cast aluminum threaded blind holes – while I’m sure the M10 x 1.5 threads would be okay, I didn’t want to take any chances of screwing them up by asking them to hold the weight of the housing (~70 pounds) + whatever force I needed to apply, which at times was significant.

Bottom line – a design like this: https://www.jegs.com/i/Richmond+Gear...020-1/10002/-1 could be made to work, but would not be my first choice, and it is also pretty pricey.

You could also go to the other end of the spectrum and just clamp it in a vise like this (source: https://driveviper.com/forums/thread...l=1#post292246):

It clearly works, but you need to be able to flip the differential 180° pretty often during a rebuild, and that would not be easy with a vise. Fully loaded, that’s a two-person job. No thanks – I usually work solo.

Bryan (cowger) made his own differential holder out of scrap steel, and used the differential housing’s front mounting points along with the bushings to hold it in place, which I thought was a very clever design:

Now we're talking.

I decided to make something similar, but I had three major problems:

1. I didn’t have a welder

2. I had never welded anything in my life

3. I didn’t have any scrap steel laying around

But those things can be fixed. So off to Harbor Freight I went.

I could make an entire post about welding, but it would likely only serve as a distraction, and since I’m no pro, I’m sure it would be riddled with inaccuracies and poor advice.

To make a long story short, I wanted a cost-effective solution, but I didn’t have a dedicated 240V circuit in my garage to run a nice welder. I did have plenty of 120V, 20-amp outlets throughout my garage, though, so that was a good start. As for the welding process, I decided on flux-cored (a.k.a. FCAW, or flux-cored arc welding) rather than the hugely more expensive MIG or TIG setups. There’s also stick welders, but flux-cored is much easier to learn than stick welding. Flux-cored only machines are pretty affordable, and as long as you are willing to accept their shortcomings (e.g. lots of weld spatter and not-so-pretty welds), they are quite capable. Cheaper 120V machines definitely hamper what you can do in terms of duty cycle (i.e. how long you can weld in one go before you have to let the machine cool off) and material thickness (my machine was only good up to 3/16” thick steel), but I decided I could work around that. The material thickness limitation meant I couldn’t just copy what Bryan made, as he used 1/4" thick steel bar stock. I’ll address that in a second.

Since it might be helpful, I’ll at least give you a list of what I bought to become a YouTube certified welder:

1. Harbor Freight Titanium Flux 125: https://www.harborfreight.com/easy-f...der-56355.html

2. Portable welding table: https://www.harborfreight.com/adjust...ble-61369.html

3. F-style clamps (x2): https://www.harborfreight.com/12-in-...amp-63512.html

4. 90-degree magnetic clamps: https://www.harborfreight.com/4-piec...ers-93898.html

5. Bigger 90-degree magnetic clamps: https://www.harborfreight.com/35-lb-...net-63798.html

6. Extra tips (didn’t end up needing them): https://www.harborfreight.com/0030-i...ack-63790.html

7. A really nice Lincoln Viking 3350 helmet (plenty of cheaper options out there though): https://www.amazon.com/gp/product/B07V9G94NK/

8. Do rag: https://www.amazon.com/gp/product/B00BYF64X2/

9. Leather welding apron: https://www.amazon.com/gp/product/B0876Y62Z5/

10. 0.030 multi-pass flux-cored wire: https://www.homedepot.com/p/Lincoln-...1448/100341108

11. Welding gloves: https://www.homedepot.com/p/Lincoln-...H643/100341058

12. Wire brush to remove the slag: https://www.homedepot.com/p/Lincoln-...H584/100341124

13. Chipping hammer (wasn’t all that useful): https://www.homedepot.com/p/Lincoln-...H530/100341076

14. Nozzle gel: https://www.amazon.com/Hobart-770074...0017Z5J1W?th=1

You’ll also need an angle grinder, or some other way of cutting steel to the right size/shape. I already had one of those along with various cutting and grinding wheels.

But how would I hold it to my work bench? How about a bolt-on trailer hitch receiver or two? https://www.amazon.com/gp/product/B087B4BLMP/ These were nice because they had a provision for an anti-rattle bolt that came in quite handy for holding the fixture firmly in place.

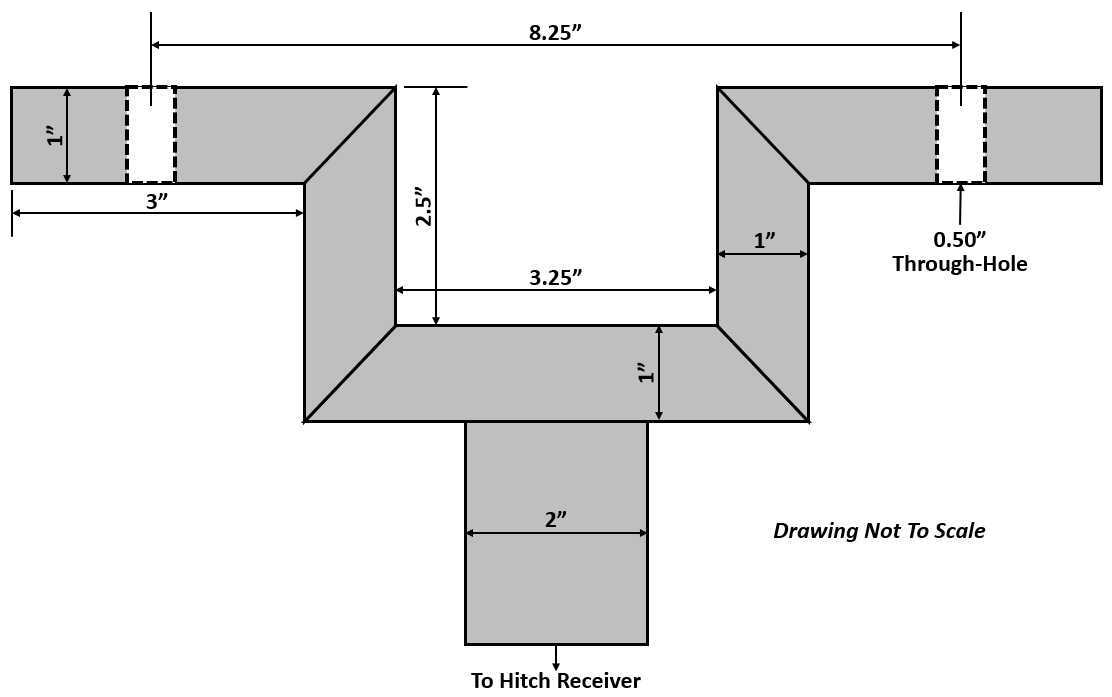

Since I couldn’t use 1/4" steel bar, and since I intended to make the differential mount compatible with the 2” trailer hitch receiver, I had to change Bryan’s design. I used the following supplies:

1. 2” x 2” x 0.12” wall thickness square tubing (welded structural mild steel) – 3 feet

2. 2” x 1” x 0.12” wall thickness rectangular tubing (welded structural mild steel) – 3 feet

3. 1” wide, 1/8” thick mild steel bar stock – 2 feet

…and aimed to make the following design:

All angles are 45-degrees. I made sure all materials were about the same thickness to make picking the right settings on the welder easier (aside: the chart on the machine was a great starting point for the settings). I’ll say this about the cuts: I did them all by hand with an angle grinder, and that sucked. It’s pretty hard to make accurate 45-degree cuts just by eyeballing them – the first couple of pieces I tried to mock up were so horribly aligned that I knew I was in for a long day. Later on in this project I ended up buying this bench top belt sander, which would have made my life so much easier: https://www.harborfreight.com/4-in-x...der-58339.html You could also use a chop saw, but those were substantially more expensive than the belt sander.

Regardless, I powered through with my angle grinder and started sticking pieces of steel together. Yeah, it ain’t pretty with all the weld spatter, but did it stick them together? Yes it did. Note the size of the welder on the floor…pretty small considering what it can do:

Since I was going to be clamping down on the fixture pretty hard with large-ish bolts to hold the differential, I wanted to reinforce the inside of the rectangular tube sections with the 1/2" through holes. I did that by cutting two 3/4" long pieces of the same 1” x 2” rectangular tubing, turning it sideways, jamming it in there, and tacking it in place (one on each side):

And I decided to add some end caps to keep spiders from nesting in it…I already had a welder and some 1/8” thick bar stock, so why not?

A grinder and some paint make me the welder I ain’t (although I haven’t painted it yet).

I slid the fixture into the hitch receivers bolted to my work bench top, and hung on it to make sure it would hold. I weigh about 225 pounds, and this thing didn’t flex one bit. Like, at all. It was clearly way overkill for holding a 70-ish pound differential, but that is one very expensive piece of hardware, and I didn’t want it crashing to the floor at any point during the next phases of this adventure.

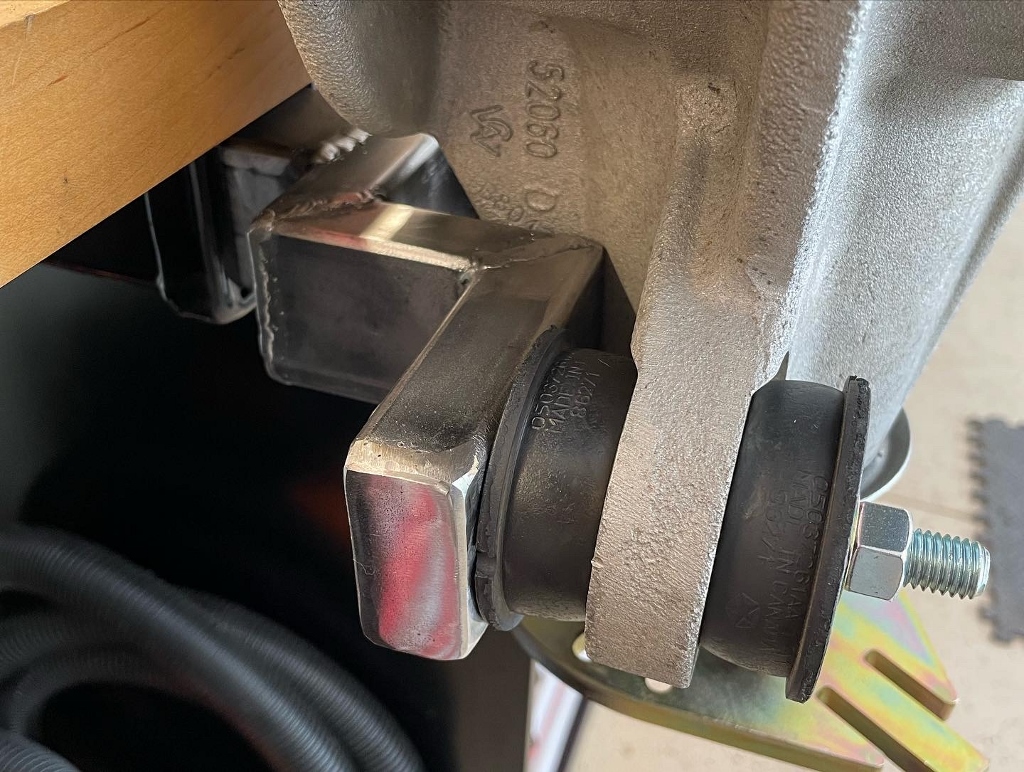

All that was left was to do was bolt the differential to it and heave it up in to place (easier said than done). The bolts are 12 mm x 1.75 x 120 mm grade 10.9 bolts along with a couple of flat washers and matching nuts. If you want an extra pair of the differential mounting bushings to avoid the down time like I did, brace yourself; they are incredibly expensive. You’ll need 4 of these (https://viperpartsdepot.com/products...40345295913136) and 2 of these (https://viperpartsdepot.com/products...40345295945904). Expect to pay $200+ for the full set. Total horseshit, but I digress.

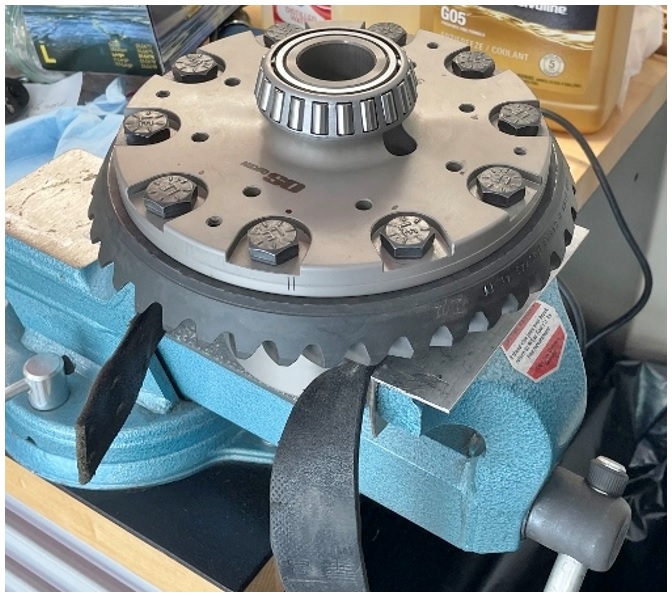

Finished product:

And what it looks like underneath:

Bonus: I could still park my truck in the garage even with the differential mounted to my work bench. Which was nice, because that thing was a bitch to lift up to my standing-height work bench.

Just don’t ask me how long all that took.

Now it’s time to actually get started on this project.Last edited by Steve M; 12-23-2022 at 11:47 AM.

-

10-05-2022 #14Enthusiast

- Join Date

- Nov 2021

- Location

- Western PA

- Posts

- 254

Great work there!

I am still not sure I would attempt this myself, but it does give me a glimmer of hope.

One of the best write-ups and documentation I have seen. Great ingenuity as well! Kudos!

-

10-05-2022 #15Enthusiast

- Join Date

- Jan 2015

- Location

- Houston

- Posts

- 276

Whats the current shop rate to get this done?

-

10-05-2022 #16Enthusiast

- Join Date

- Nov 2021

- Location

- Western PA

- Posts

- 254

-

10-05-2022 #17Enthusiast

- Join Date

- Sep 2018

- Posts

- 116

I could not find a local shop to undertake the project. I guess my mistake was to gather my own parts, but no one wants to touch a car w/parts not from their shop. I bought a spare diff and a most of tools on the list, but life keeps pushing the project back....

-

10-05-2022 #18Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

Thanks! Still gotta get the rest of the info on here, but I'm getting there. Tear down is next.

I have no idea. Never even asked around. I can give you a ballpark estimate of what I think it should take time-wise though, assuming they are experienced and have absolutely everything they need to do the job properly:

1. Tear down - 1-2 hours. This should include draining the fluid, measuring the pinion and carrier bearing preloads, backlash, carrier shim thicknesses, pinion shim thickness (which means they'll have to pull the bearing), popping out the seals, removing the pinion bearing cups/outer races, and cleaning everything up including all of the old RTV on the cover and the case. The measurements are all especially important because they'll serve as your starting point for the shims that will go with your new ring and pinion.

2. Pressing on the carrier bearings, pinion bearing cups, and installing the new ring gear - 30 minutes to 1 hour.

3. Running gear patterns - each pattern will take about 1 hour if you are proficient. An experienced installer will probably get it right in 3 or 4 tries. It took me 16 tries. Most of that time is spent getting the backlash right, and cleaning off the gear marking compound between setups.

4. Final setup - 1 hour. This should include documentation of all specs - bearing preload values, backlash measured at multiple points, and a final pattern check to make sure nothing weird is going on.

5. Add 1 hour for a solid pinion bearing spacer.

6. Add 2 hours if they have to remove and reinstall the differential in the car.

So I'd say budget about 8-10 hours total if they have their feces together. Some might be able to do it quicker, but I'd question just how thorough they were.

You also need to ask the shop some questions and take note of their answers:

1. What specs are they going to use? Pinion bearing preload, carrier bearing preload, bolt torque specs (carrier bearing cap bolts, ring gear bolts, etc.), backlash, etc. all need to be understood and agreed upon before hand.

2. How much experience do they have setting up 2-cut gears? All of the Dana Spicer gears listed above are 2-cut, and set up a bit differently than aftermarket 5-cut gears. For example, they use substantially tighter backlash specs, and the gear patterns look nothing like a 5-cut gear pattern.

3. Are they willing to let you supply parts?

The list could go on, but I think you get the point. This ain't rocket science, but details matter.

If you get frustrated and find yourself in Dayton, bring it by. Always happy to help out a fellow Viper owner.

-

10-06-2022 #19Enthusiast

- Join Date

- Nov 2016

- Posts

- 644

I supplied all parts, and my shop charged 9 hours plus fluid. That was with the Diff in the car. I think he lost money? $100 an hour!

-

10-08-2022 #20Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

I can still smell the gear oil

Tear Down

I hope you like the smell of gear oil, because you’ll be smelling it for a while.

Step 1. Drain the old oil.

My differential mounting fixture design allowed me to clock the differential housing every 90 degrees, so I turned mine sideways and drained most of the oil by removing the fill plug (now oriented down) as seen below:

Note the Gen 5 stub axles – those were in place because that differential still had the original GKN Visco Lok limited slip carrier/differential installed. As a reminder, the GKN Visco Lok came in both the Gen 4 and Gen 5 Vipers – hopefully this proves that the Gen 4 and Gen 5 stub axles are interchangeable. They were installed to keep the housing sealed while it was in storage. They are also really, really easy to remove since you have something to grab onto with a slide hammer. Once you have drained most of the fluid (you won’t get it all), the stubs can come out.

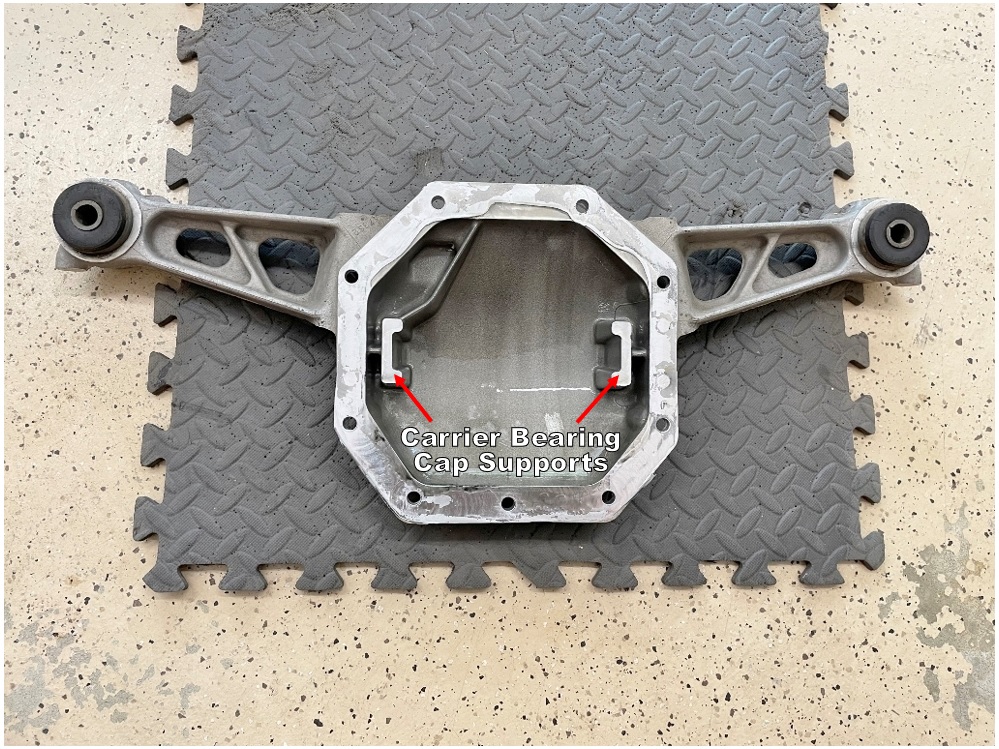

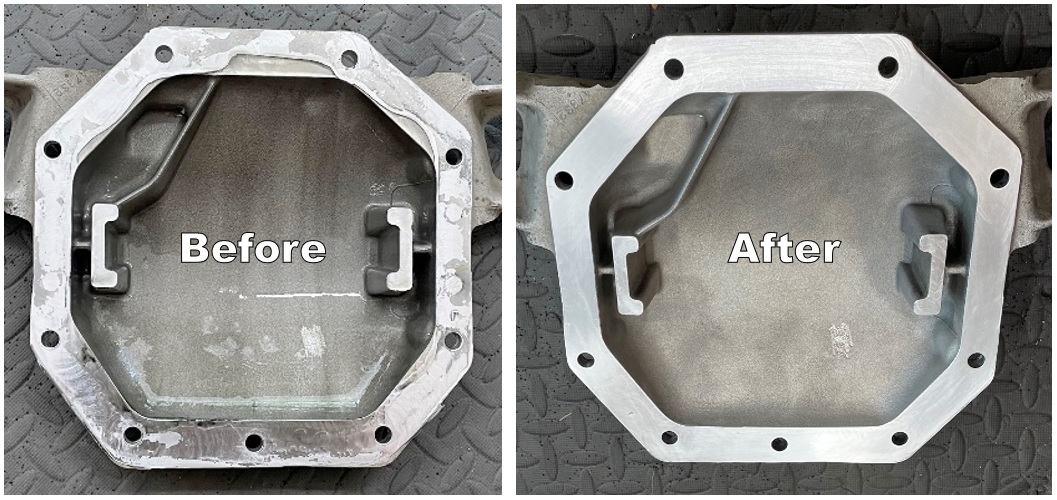

Step 2. Remove the differential cover.

To get the differential cover off, you’ll need to remove the 9 bolts that hold it in place. They are M10 x 1.5 x 30 mm flange head bolts, and take a 13 mm 6-point socket to remove. Most will be a little tight since they will have RTV on them, but all of mine came out without issue. You’ll be reusing these, so clean them up and set them aside, preferably in a plastic baggie so you don’t lose any of them.

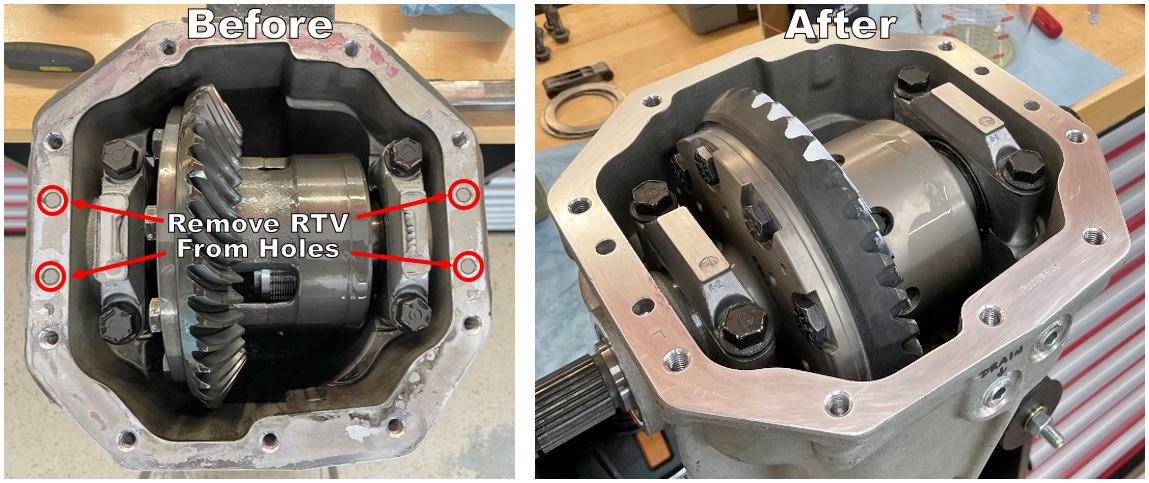

Once the bolts are out, you can just smack one of the ends of batwings with your hand (or a dead blow hammer) and it’ll just pop right off, leaving you with this:

Note the carrier bearing cap supports that are cast/machined into the cover; these add strength to the assembly.

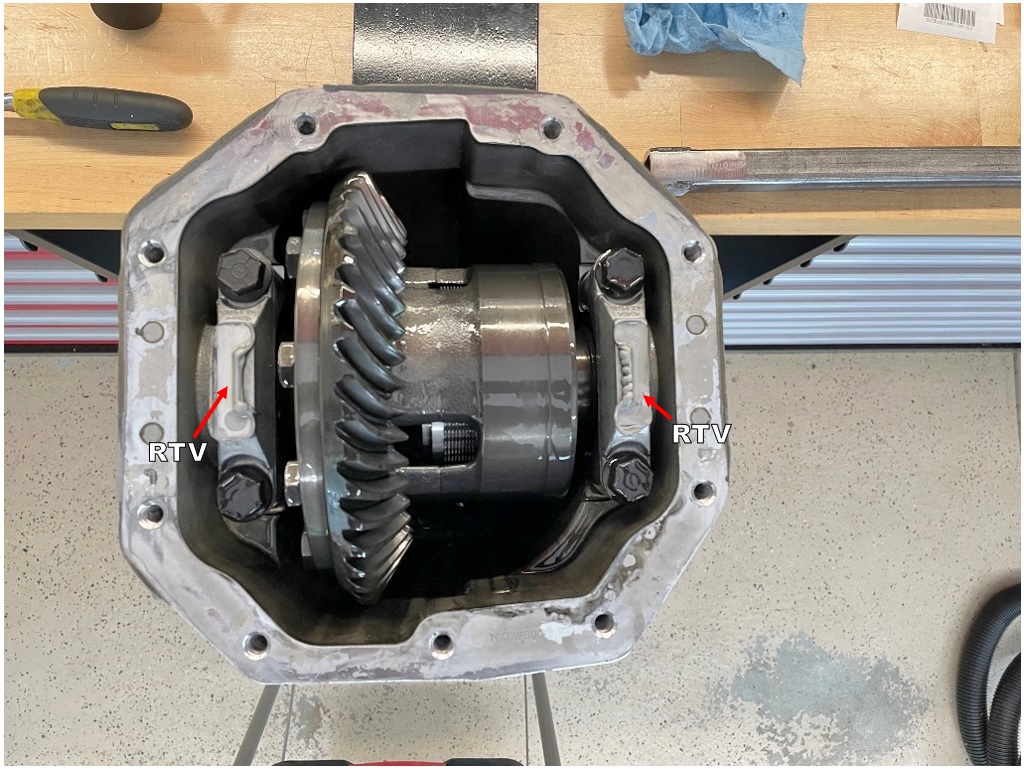

Step 3. Take a good whiff of that gear oil. Mmmmmmmmmmm.

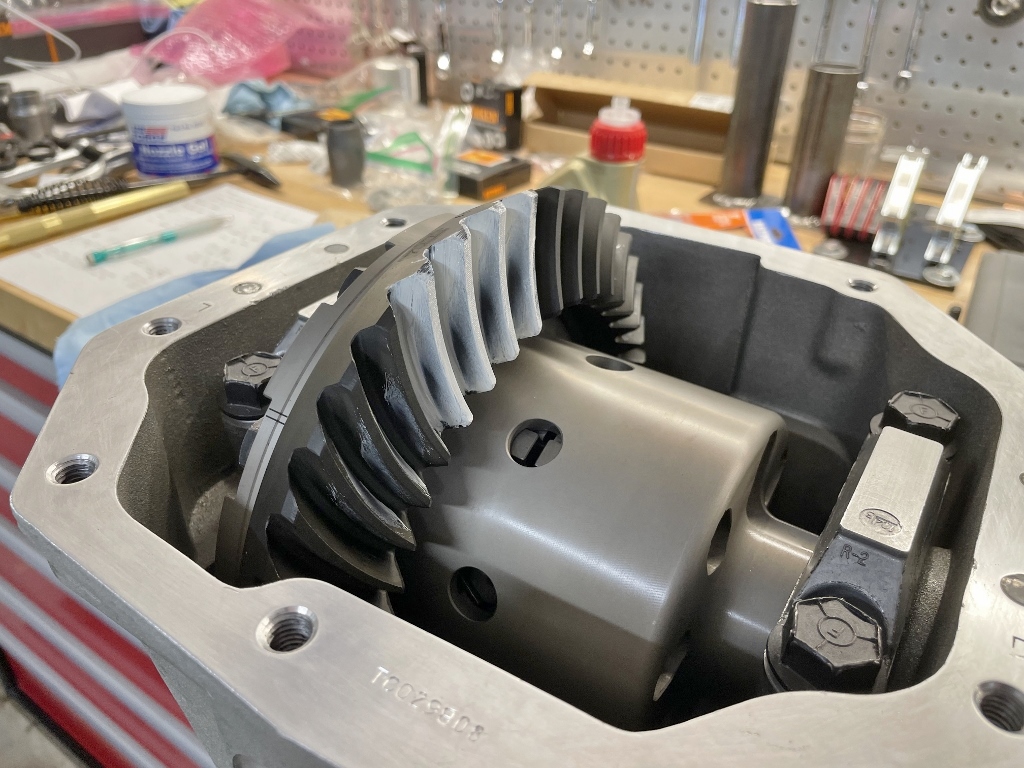

Set the differential cover aside…you won’t be needing that for a while. You’ll be spending the next countless hours of your life dealing with this smelly mess:

Note the RTV on the carrier bearing caps – this is a critical part of the final assembly process, so you’ll be seeing something about this again in one of my later posts. Bottom line: the RTV is there to bridge the gap between the carrier bearing caps and the cap supports in the differential cover. It ain’t much of a gap, but one definitely exists as they aren’t machined to the exact tolerances required for a zero-clearance fit.

Remove the RTV from the carrier bearing caps.

Step 4. Examine the gear wear pattern.

Chances are good that you won’t be reusing your ring and pinion, so while this doesn’t really matter, it will give you insights into how your differential lived its life.

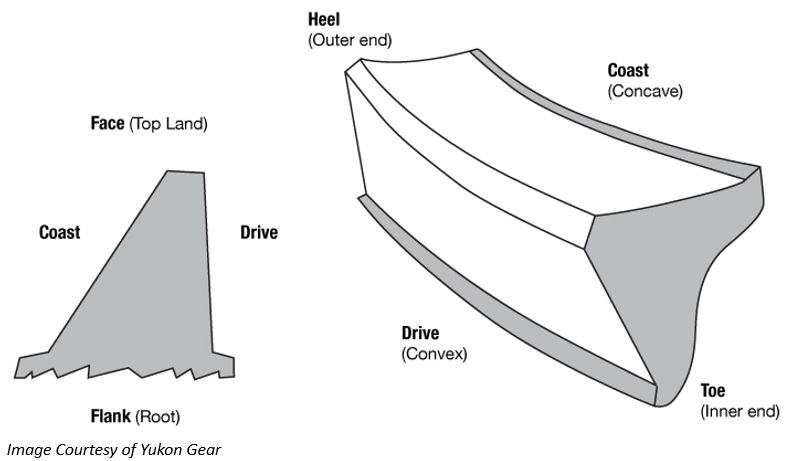

First, a diagram courtesy of Yukon Gear showing the anatomy of a ring gear (source: https://www.yukongear.com/blogs/how-...r-patterns_1):

I’ll end up using terms like heel/toe, drive/coast, etc. later on, so if you get lost, refer back to this diagram.

Here’s what mine looked like:

Coast wear was pretty well centered, slightly favoring the toe (inner) side of the ring gear teeth. The drive side wear was similar, but definitely favored the toe side of the teeth. Overall, no chipped teeth, and nothing to suggest that they got overheated at any point during their life.

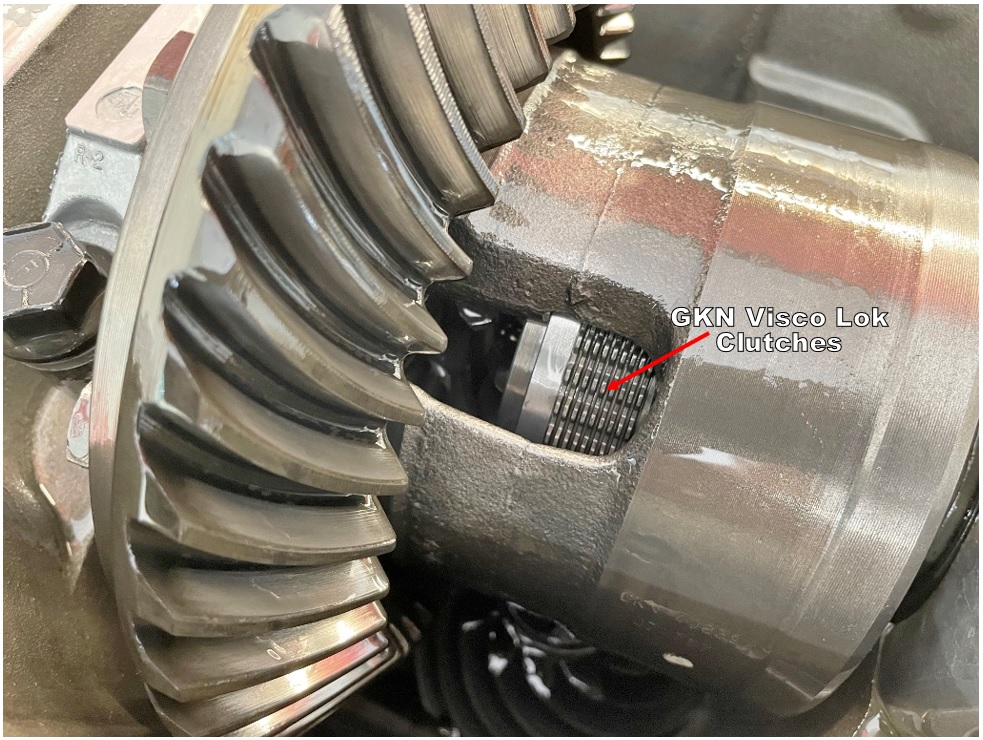

And here’s a shot showing the GKN Visco Lok clutches:

No real point to the picture other than to show you what it looks like, and to serve as a reference if you are trying to figure out what limited slip unit is installed in your housing. That’s what a GKN Visco Lok looks like.

Step 5. Measure total bearing preload.

Flip the housing over, but be prepared for the rest of the gear oil to come pouring out. Grab your inch-pound, needle or dial-style torque wrench, your 1-5/16” socket, and a 1/4" to 1/2” socket adapter. Tip: when installing the pinion yoke holding tool (which can be done anytime), put the socket on the pinion nut first – this will allow you to easily center the yoke holding tool before you cinch it down to the yoke. The pinion yoke holding tool will stay in place throughout this process.

To measure the total bearing preload (pinion bearings + carrier bearings), spin the torque wrench around in one direction 3-4 full turns, and while you are still turning, take a reading. This takes a bit of practice since you’ll be trying to eyeball a moving target, but you’ll get the hang of it. What you do not want to do is to measure how much torque it takes to start the pinion moving – this value will be higher than the torque required to keep it rotating. You want the torque to rotate measurement to reflect what it takes to keep it rotating.

The total torque to rotate for mine was about 22 inch-pounds, which was in spec for used bearings. This does not tell you the full story, though. I’ll get to that in a second, but there are a couple more things you need to check first.

Step 6. Measure backlash and ring gear runout.

Flip the housing back over (you’ll be doing this a lot).

Grab your dial indicator and all of the adapters needed to screw it into the differential housing cover bolt holes. As a reminder, all of the stuff needed to do that is listed in the Tools post above.

It’ll look something like this:

I’ll add more details about exactly how to measure backlash and ring gear runout in my next post.

Backlash measured between 0.000 - 0.001”, which was WAY too tight. That explains why the wear favored the toe side of the tooth, and why the gears made so much noise, especially when they got hot. The correct spec is 0.004 - 0.006” according to the service manual.

To be clear, this differential had always made noise from the day I bought it with only 9,500 miles on the clock. So while drag racing didn’t do it any favors, I don’t think it was the cause. I’m guessing this differential somehow passed inspection, but probably shouldn’t have.

Ring gear runout isn’t all that important to note unless you intend to reuse your old gears. Mine measured 0.001”. Max runout spec from the manual is 0.002”, so this was good.

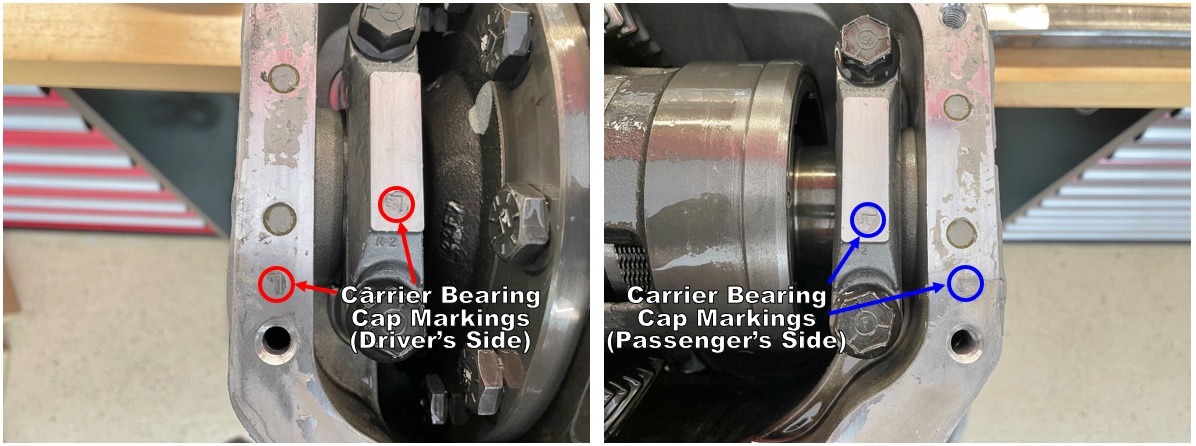

Step 7. Note carrier bearing cap markings.

This step is critically important.

The carrier bearing caps are marked to show which side they go on as well as their proper orientation. The caps must go back exactly as you found them during reassembly. This is why you had to remove the RTV from them in Step 3.

To keep them from getting mixed up, the factory stamped letters on both the housing and the caps. For mine, they used the letter “L”. Note where it is marked on the cap, and how the letters are clocked on both sides:

As oriented, the L’s on the driver’s side of the case and driver’s side carrier bearing cap are upside down. The L’s on the passenger’s side have both been rotated 90 degrees counter-clockwise.

Hopefully you can see how they made this idiot-proof – as long as the letters face the right direction on both sides, the caps are in their correct spots and orientations.

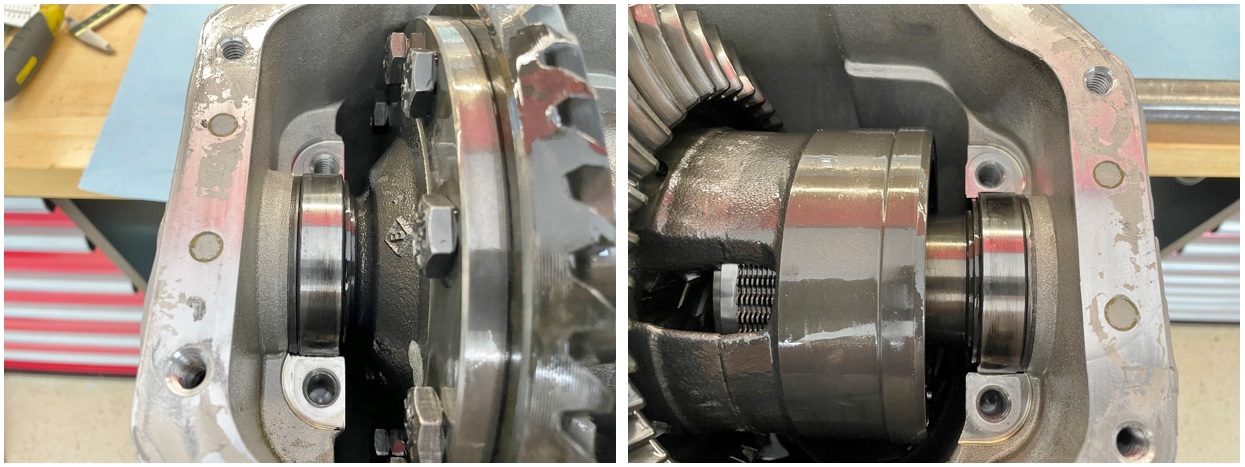

Step 8. Remove the carrier.

Now that you’ve noted the carrier bearing cap markings, you can remove the cap bolts. They take a 19 mm 6-point socket to remove:

Set the caps and bolts aside. Both will be reused.

The carrier + ring gear are wedged in the housing pretty good. If you are going to use a case spreader to help get it out, now is the time to grab it. I opted for the quicker/easier method of using a 3/4" box-end wrench slid on one of the ring gear bolts to act as a pivot against the housing, like this:

All you have to do is rotate the yoke, and the carrier will pop itself up to the point where you can grab on to the ring gear and yank it the rest of the way out. You may need to go at it with a pry bar as well, but it will come out. Tip: the box end wrench and/or pry bar will start making marks in the differential housing after you do this a few times, so put something like a piece of leather between the wrench (or pry bar) and the aluminum case to prevent that from happening. I used part of an old leather belt (not pictured).

Set the carrier aside for now.

Step 9. Measure the carrier bearing shim thicknesses.

The carrier bearing shims just sit in there…during the process of pulling the carrier out, yours might have fallen in to the housing. Do your best to keep track of which one went on which side, as this will be your starting point for setting both the backlash and carrier bearing preload for your new setup.

Pull out your micrometer, measure both, and write them down:

Mine measured:

Driver’s side carrier bearing shim – 0.1305”

Passenger’s side carrier bearing shim – 0.1340”

Step 10. Measure pinion bearing preload.

Flip the housing over, and grab your inch-pound torque wrench and pinion nut socket. You are measuring the preload again, but this time it will obviously only be your pinion bearings.

Mine, including the pinion seal, measured about 8 inch-pounds.

The pinion seal adds about 3 inch-pounds to the measurement due to friction, so we’ll call the pinion bearing preload about 5 inch-pounds, which is out of spec. The service manual calls for pinion bearing preload of 10-20 inch-pounds of torque to rotate for used bearings.

This also told me something else that was very important – the carrier bearing preload was too tight. If you’ll remember, the total preload measured in Step 5 was around 22 inch-pounds of torque to rotate. 22 minus 8 gives us 14 inch-pounds of carrier bearing preload. At face value, this seems fine, but carrier bearing preload has to take into account the torque multiplication factor of the gears installed.

Since these were 3.07 gears, 14 inch-pounds multiplied by 3.07 gives us 42.98 in-pounds of carrier bearing preload, which is way too high. For 3.07 gears, you’d want the actual value to be between 3 – 6.5 inch-pounds of added torque to rotate (as in, added to the pinion bearing preload number) to be within the factory bearing preload specs of 10-20 inch-pounds of preload. Hopefully that makes sense.

Stated another way, the preload specs should have been between 10-20 inch-pounds for the used pinion bearings by themselves. Total preload (pinion + carrier bearings fully installed) should have been 13-26 inch pounds, plus another 3 inch pounds to account for the pinion seal friction.

The carrier bearings did not appear to be any worse for the wear, so even though they were too tight, they still seemed to look okay with about 15k miles on the clock. I would not have expected them to last for a long time (like 100k+ miles), though.

Step 11. Remove the pinion nut, yoke, seal, oil slinger, and pinion gear.

Time to remove that pinion nut. If you try this by hand, good luck. I used my 1/2" breaker bar plus my custom 3-foot cheater that went on the pinion yoke holding tool, and I was not able to get the nut to budge. My Milwaukee 1/2" impact zipped it right off though. Toss the nut – you won’t be reusing it. Set the old pinion nut washer aside – you won’t use it during final assembly, but you can use it during your initial setups so you can keep your new washer pristine for final assembly.

A couple taps from underneath the pinion yoke holding tool was enough to remove the yoke. Set this aside for now.

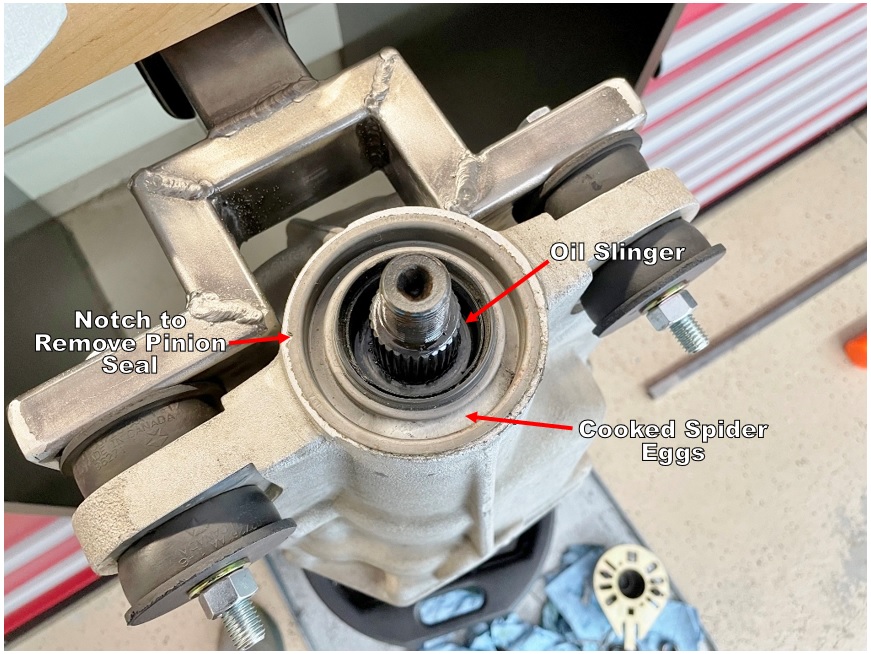

You can remove the pinion seal next. There is a notch in the seal to help with this. See picture below. Note the spider eggs – this also happened to Bryan (cowger’s), which I found amusing. Guess I need to drive the car more to keep spiders from wanting to nest there.

Using either a flat head screwdriver or a chisel of some sort set in the notch, you can collapse the seal by hammering it in towards the center enough to allow you to get a small pry bar underneath to remove it. Clearly you won’t be reusing this, but take care not to damage the differential housing in the process of getting it out.

Once that is out, you’ll see a large black flat washer – this is the oil slinger. You’ll be reusing this during final assembly, so set it aside, but don’t lose it.

With the differential housing snout still facing up, grab your 4 pound dead blow hammer and get ready to relieve some frustration. With your hand underneath supporting the pinion gear from inside the housing, give the snout a few sharp taps from the outside and the pinion will release from the outer pinion bearing. That’s why you need to support it from the other side…otherwise, it’ll go crashing to the ground (or worse, into your toes). It’s heavier than it looks.

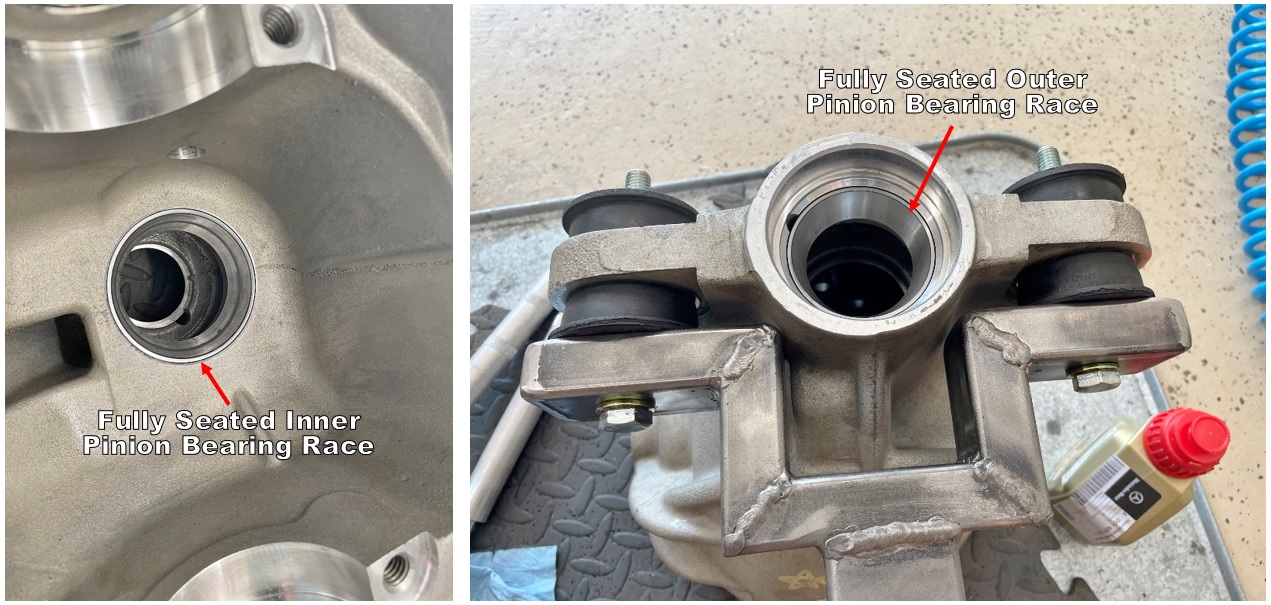

Step 12. Remove the pinion bearing races/cups.

This part of the project is not a delicate operation. In order to remove the inner and outer pinion bearing races/cups that are pressed into the housing, you’ll need two things:

1. A long punch

2. A sledge hammer

I did not have a long enough punch to reach through the inside of the housing to the back side of the outer pinion bearing race, or at least so I thought. After a brief bit of cussing at my lack of foresight, I finally looked at the Lisle 59400 bearing race driver set and realized that a long punch suitable for this task was included in the kit:

This project was humbling to say the least…after I got done feeling like a dumb ass, I got back to work.

Getting the races out takes some serious force, and is why I recommend a sledge hammer instead of the non-marring dead blow hammer that I used for everything else.

The process goes something like this: seat the punch on one side of the bearing race, and give it a few hard taps. Move the tap to the opposite side and give it some more taps. Keep moving the punch back and forth to keep the race moving out – if you don’t, it’ll get jammed in there pretty good. It took me a few minutes of hard banging to get each one out.

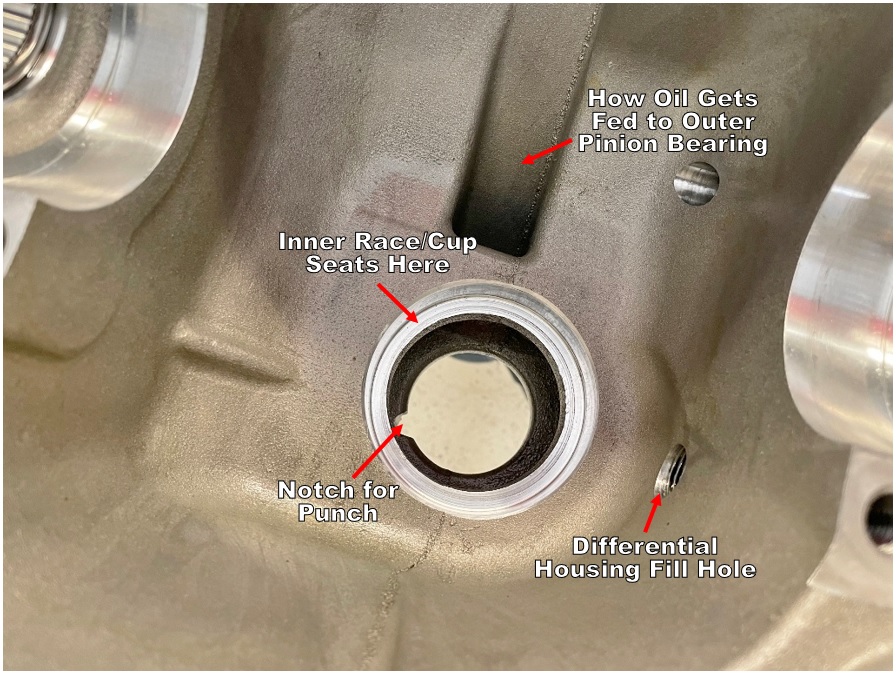

The differential housing where the outer race sits has a notch that you can use to put the punch on one side, as shown in the picture below:

The inner race has no such notch, and there isn’t much of a lip to grab onto with the punch, but just keep moving the punch back and forth on the back side of the race while hitting it and it’ll come out too:

Note the channel cast into the housing – oil gets slung up by the ring gear and into this channel to feed oil to the outer pinion bearing. Clever.

Step 13. Remove the old pinion and carrier bearings.

Just about done here.

All that’s left to do is remove the inner pinion bearing pressed on to the old pinion gear. This is where the clamshell bearing puller comes in really handy. Grab the outer race you just removed from the case, and place it on the bearing cone. Put the bearing puller on top of this assembly, tighten everything down, and zip it off with an impact wrench. The clamshell puller pulls the bearing off by grabbing on to the bearing cage. This is not a very strong part of the bearing, which is why you need the outer race. The clamshell puller will force the cage + rollers up into the lip of the inner race, and the outer race provides support for the rollers from the other side. The even pressure applied by this tool is what keeps the bearing from being damaged during removal, which is a huge plus. The video linked above shows how to use this tool in great detail…watch it all the way through, and then watch it again. I highly, highly recommend this tool, even if this is the only differential you ever rebuild. It was well worth the added expense IMO.

Once that bearing is off, you’ll have access to the pinion bearing shim. Mine measured 0.048”…this will be the starting point for your new setup.

You can also remove the carrier bearings using the same clamshell bearing puller tool. There’s an adapter that allows you to do this already included with the kit. Again, watch the video…it has all the info you need.

The last thing you can do is remove the stub axle seals. I got these out with a small pry bar (not pictured).

-

10-09-2022 #21Enthusiast

- Join Date

- Oct 2013

- Location