Thinking of swapping the engine mounts in your Gen 4 Viper?

Don't.

Seriously, unless you suspect something is really wrong, or unless you are already doing a header install, it just isn't worth it.

Why? I know others on here have commented about how much of a pain it is, but after looking at it from underneath the car, I couldn't see what the fuss was all about. You can easily access the 3 bolts and one nut you need to get to, so what could possibly be so hard? Well, the answer is because the exhaust is directly in the way of how you need to fish them out from under the engine, and that's on the driver's side where you have tons of room to work. If you are thinking about doing something similar on the passenger's side with even less room to work, you can forget about it.

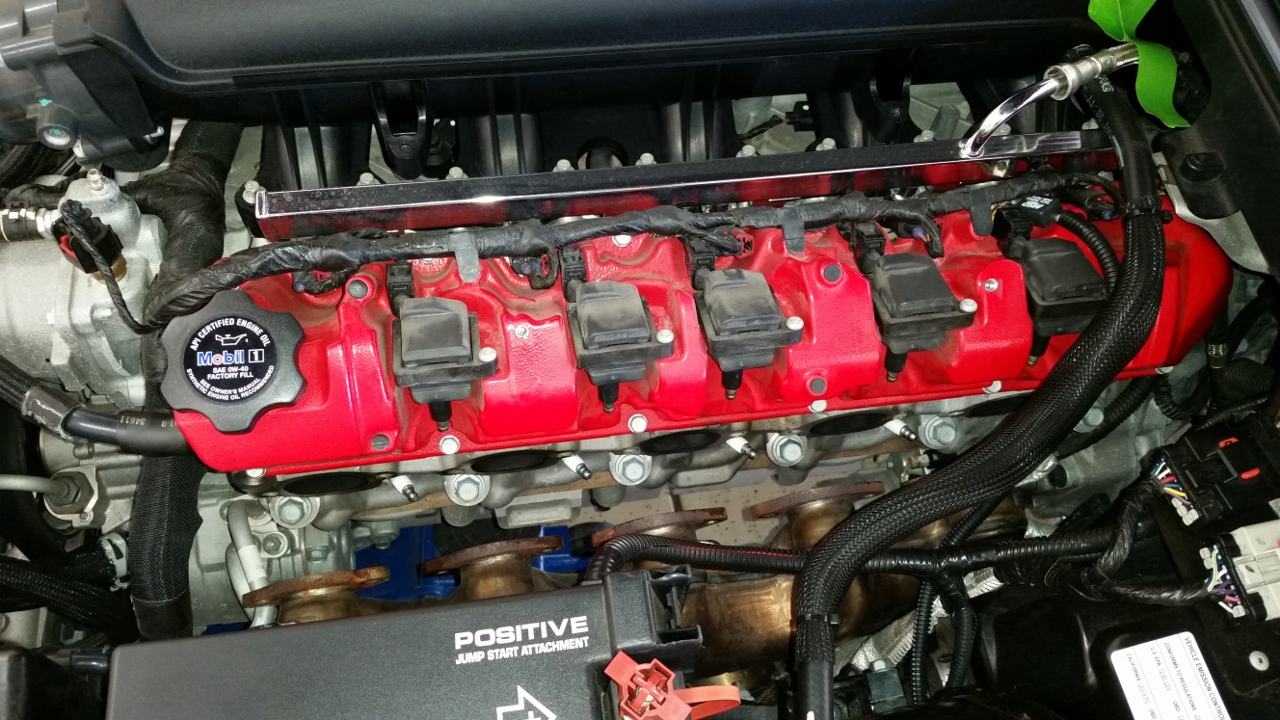

This is the current state of my engine bay:

Wait, aren't those exhaust manifolds supposed to be attached?

Anyone need a good shot of the spark plugs?

I originally wanted to do this because under heavy throttle, my engine twists to the right pretty good, enough so that it can make shifting fast a bit of a chore at the drag strip. My car is 11 years old at this point with ~16,000 miles on the clock, so I figured it was worth at least trying to see if the driver's side engine mount was starting to give up the ghost. At this point, I'm elbow deep in it, so I might as well share my lessons learned so far. And I say "so far" because I have no idea how long it's going to take me to get everything back together, but by golly, I got one whole engine mount out. Not in, just out.

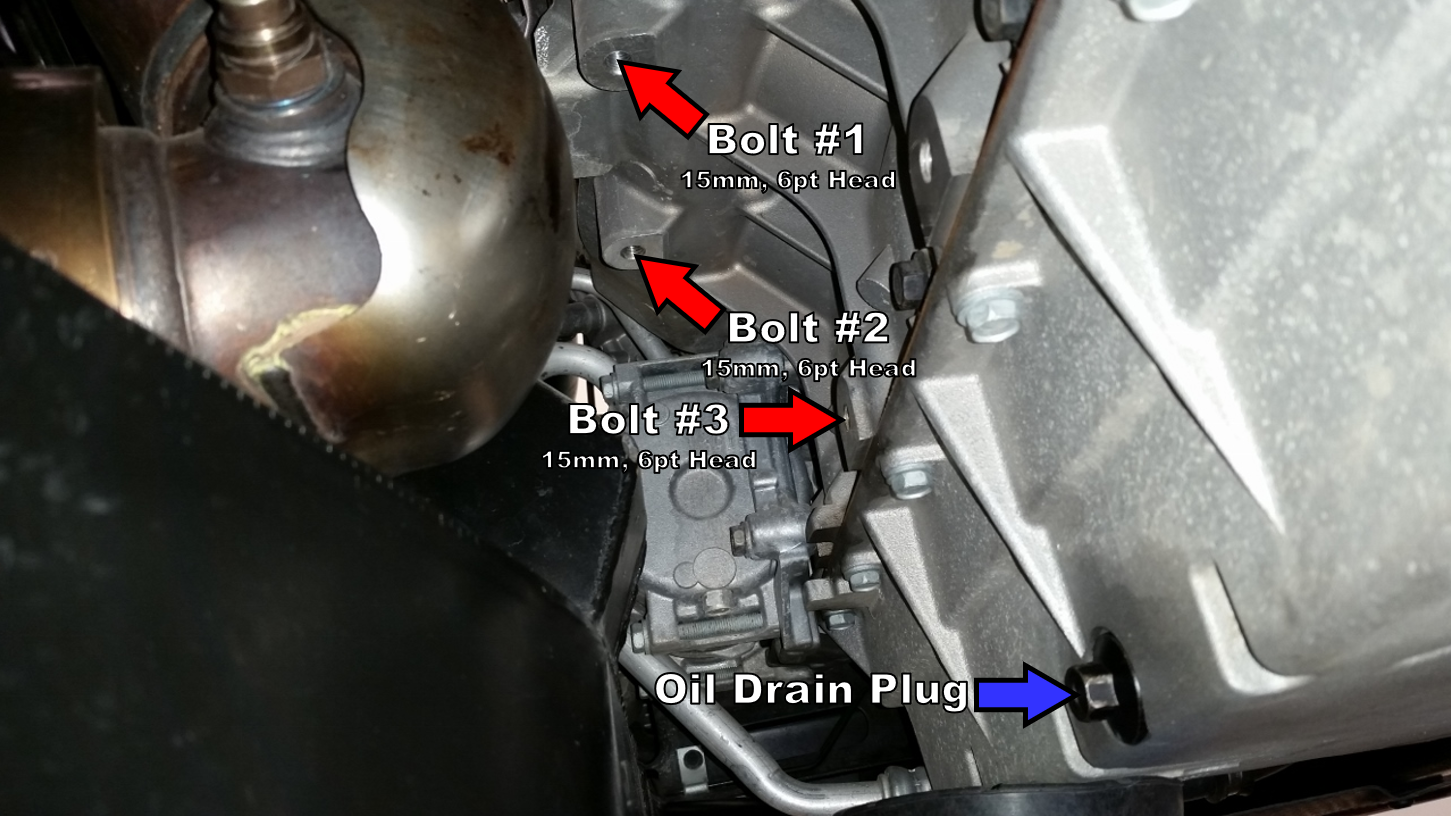

1. It really is as simple as only 3 bolts and one nut holding everything in place. The engine mount to block bolts take a 15mm, 6-point socket to remove, and the nut takes a 19mm, 6-point socket. All are pretty easy to access, and none of them were super tight. See picture below for reference as to where everything is, with an arrow pointing to the oil drain plug to help orient you:

2. Removing the exhaust manifold bolts wouldn't have been a huge deal, but they must have used some sort of anti-seize at the factory during assembly. That would theoretically make them easier to remove, unless you cake it on too much like they did, and then it makes it a royal pain to remove them. 4 out of the 10 bolts had me concerned that I was going to pull the threads in the heads out right along with them - thankfully, I didn't.

3. The nut that holds the rubber engine mount to the aluminum bracket is another 19mm, 6-point head. This one was a royal PITA to remove. I had to take my 1/2" impact to it, and even then, I could only get it out so far with it clamped in my vise before the engine mount started spinning. I ended up having the clamp the mount in place with an additional c-clamp to get the nut the rest of the way off. The culprit? Rust, and lots of it. My car never sees rain or snow, and it only gets washed a few times a year at most. It will be going back in the car with some sort of grease on it to keep that from happening again with the new mount.

Here are some pics of the mounts so you will at least know what you are looking for:

From the bottom, with the new mount sitting to the left of the assembly:

From the side - you can see the heat shield pretty well in this one:

And what it looks like from the top, just prior to me fighting with the nut referenced in lesson learned #3 above:

Everyone can now laugh at my expense. I can assure you, I will not be doing the passenger side mount, especially considering outside of a couple small cracks, the original driver's side mount was still good.

Results 1 to 11 of 11

Hybrid View

-

08-10-2019 #1Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

Gen 4 Engine Mount Word of Warning

-

08-11-2019 #2Enthusiast

- Join Date

- Oct 2013

- Location

- Edmonton

- Posts

- 784

Steve I’ve changed mine 4 times now lol. They are much easier with aftermarket headers in place. I left headers attached, removed the front bar, and unhooked the exhaust at the turnouts. I only removed the mounts them selves and left the brackets in place..

-

08-11-2019 #3Enthusiast

- Join Date

- Dec 2018

- Location

- North Alabama

- Posts

- 774

-

08-11-2019 #4Enthusiast

- Join Date

- Oct 2013

- Location

- Edmonton

- Posts

- 784

-

08-11-2019 #5Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

-

08-11-2019 #6Enthusiast

- Join Date

- Nov 2013

- Location

- Indianapolis

- Posts

- 1,256

Thanks for the info Steve. I bought the OEM motor and transmission mounts thinking the same as you....probably getting old/dried out/rotted. I haven't done mine yet as I was waiting till I did my clutch/FW install. I may pass and just hand them to our skilled Viper tech Tom Sessions during his annual visit to Indy. LOL

-

08-11-2019 #7Enthusiast

- Join Date

- Oct 2013

- Location

- Dayton, OH

- Posts

- 4,803

I would highly recommend that approach.

Holy crap this has turned into a nightmare of a project. I did manage to get the new motor mount in without too much trouble, but it ended up messing up my exhaust tip alignment, so off came the side sills today to fix that little issue. Everything is back together for the moment, but I still have a couple more things to take care of before I put the car back on the ground to see if it did anything worthwhile.

-

08-13-2019 #8Enthusiast

- Join Date

- Nov 2016

- Posts

- 786

Hmmmm. Good stuff.

Something to consider if swap the exhaust again.

Had my mitts down in there once already, so its been known to happen!

-

12-14-2019 #9Enthusiast

- Join Date

- Jan 2018

- Location

- AZ, CA, VA

- Posts

- 351

Bringing this thread back. I am in the process of doing engine and trans mount, I couldn't find a solution for the passenger side mount so I'll post what I did and hopefully it helps someone out.

The driver side came out with no fuss, the mount separated from the bracket with no issues or stuck bolt/nuts.

Then there's the passenger side... There is no way and I mean no f#$king way to get it out the bottom as one piece. So unless you can access the top nut to separate the bracket from the mount, you have one option. Bring the whole thing out the top, which is possible but a PITA. I removed the dipstick guide to make it easier. Then wiggled, twisted and pushed the assembly forward to an open space. Then Rubix cubed that bitch through the top past the coolant and AC lines.

Of this process the hardest part is wiggling the assembly forward and getting into the open space. Once that was done it only took me about 30 min to get the unit up and out. If you remove the relevant coolant lines it'd be a lot easier. Prior to getting it out I was able to rotate the assembly so the 'mount to bracket' nut was available and tried hitting the nut with an impact while it was in the open space and it didn't move so it had to come out. Side note I put CLR on it to try to loosen it, nope. Once the assembly was out I had to deal with the ONLY stock piece of hardware in this whole process. Hit it with a ratchet, no cheater bar because I've seen too many broken threads. Then back to the impact, after 5 minutes of back and forth of this, plus more CLR, the nut came off.

I haven't gotten it back in yet but the plan is to put the bracket and mount into that empty space as individual pieces and then reassemble it in the open space. Wiggle the assemble back to where it needs to be, button everything up and then start on the trans.

-

12-16-2019 #10Enthusiast

- Join Date

- Oct 2013

- Location

- Tampa / Kuwait

- Posts

- 836

I think I removed the oil pan to get the passenger side out.

-

12-18-2019 #11Enthusiast

- Join Date

- Jan 2018

- Location

- AZ, CA, VA

- Posts

- 351

Update, on getting the passenger side back in.

Everything was going according to plan, set pieces down into the cavity and reassembled. Went back into place super easy with aftermarket mounts. Then came the process of lining up the bolts. Since the new mounts are ploy and everything was stiff I couldn't get bolts to lineup... at all. I flipped and swapped everything imaginable and nothing would work.

Driver side: The ISSUE; bottom part of bracket was not close enough to motor to seat bolt.

The SOLUTION; Set top two bolts and frame nut in place, leaving the bottom bolt out as it would not line up. Turned just enough threads to keep everything secure, then placed a bottle jack directly under the bracket to push it into place. SUCCESS.

Passenger side: The ISSUE; The opposing bolt head would fall too low to seat on frame when the engine was lowered.

The SOLUTION: Seat bracket with 3 bolts, then place a low profile scissor jack on driver side between frame and motor, very easy fit almost like it was designed to go there. Apply just enough pressure to push the motor towards the passenger side as you lower the engine in place. SUCCESS.

Trans mount was comically easy, used Energy suspension mount.

There is some vibration with poly mounts, however I feel like it's more of a reassuring vibration then an alarming vibration. Such that, hey everything in my car is tight and in place just where it should be, not flopping around under the hood.

Side note, I read somewhere that a Viper guy changed his mounts and thought it made his car faster. I thought it was complete crap until I changed mine and can account there is certainly more torque making it to the wheels than with the broken mount, mind you my drive side was completely separated. But I couldn't be happier with how everything turned out. Also checked my brake pads, rears are good, parking brake is not rubbing, and changed out the front for low dust EBC Redstuff.

Driver Side Mount

20191213_110113.jpgLast edited by Fatman2006; 12-18-2019 at 11:29 PM.

Reply With Quote

Reply With Quote

Bookmarks