So I got my block and crank back from Prefix just before our stay at home order went into effect.

The work performed by Prefix was adding oil relief channels to the upper mains to help improve oil flow to the bearings. I believe this was done to later generations from the factory. On top of that they line honed the mains, line honed the cam bores, and hot tanked and cleaned the block afterwards. As far as the crank was concerned, since I caught everything so early, there was no real damage so a simple crank polish was all it needed. I purchased main bearings and coated rod bearings from them at the same time. As of typing this, I have yet to actually assemble anything because I have been busy prepping the rest of the car, soon though. You can see the extra little channels in the second block picture. From the factory there would only be a single hole in the center.

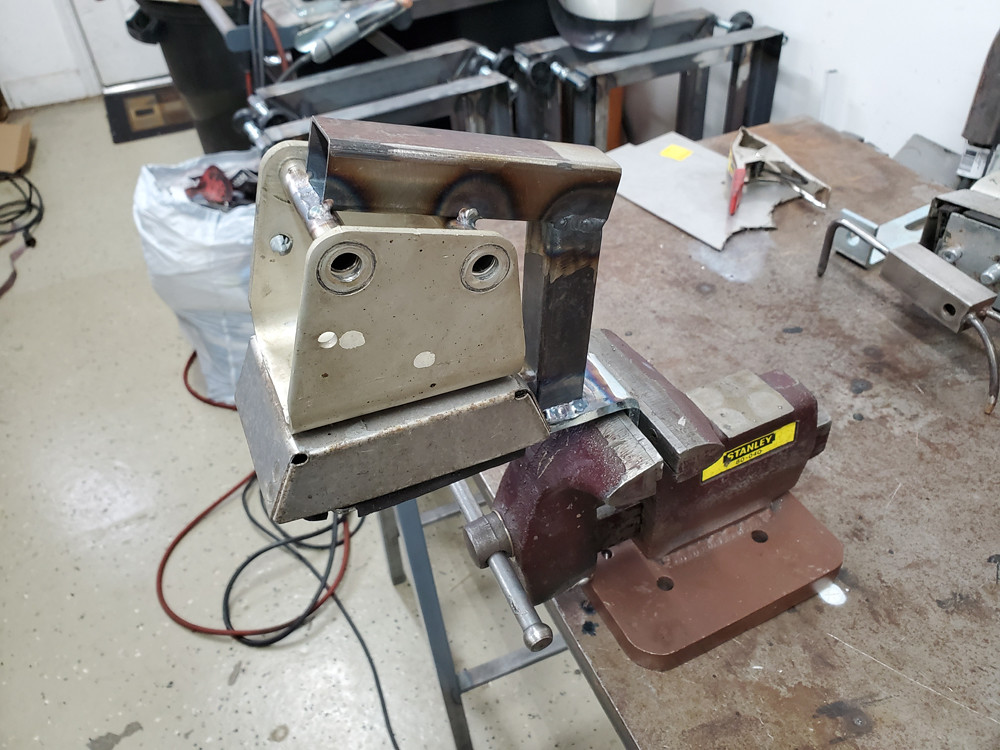

Since I had the engine back I could address one of my other problems that was the broken engine mounts. I decided to go with the tried and true round bushing style used by probably every custom off-roading truck, hot rod, sand rail, etc. Google Custom Polyurethane mounts and you will find thousands of examples on every forum imaginable. I almost bought a set of aftermarket poly Cherokee XJ mounts because they almost looked to be the right size and are super cheap and are of virtually the same design. But instead I decided to make my own. I bought the outer sleeve, bushings, and inner sleeve as a kit for $17 a set and the rest of the parts are just basic steel and aluminum flat stock from Mcmaster-Carr. A simple jig was made to locate everything to tack weld it up. Pretty simple to make and didn't cost remotely what VPUSA charges, and best of all if the polyurethane fails, you can get new bushings for around $10 and change the durometer too if they seem too stiff. Still need to make some basic heat shields. I figure if these break, you might as well write off the whole car, because I have been in a serious accident. Haha

Results 1 to 25 of 80

Thread: Prepping my GTS for the Track

Threaded View

-

04-14-2020 #11Enthusiast

- Join Date

- Jul 2017

- Location

- Michigan

- Posts

- 71

Reply With Quote

Reply With Quote

Bookmarks