So, short recap: AP Titanium exhaust broke at the catalytic converter, both sides. Driver's side broke first, melted/destroyed heat shield on that side only.

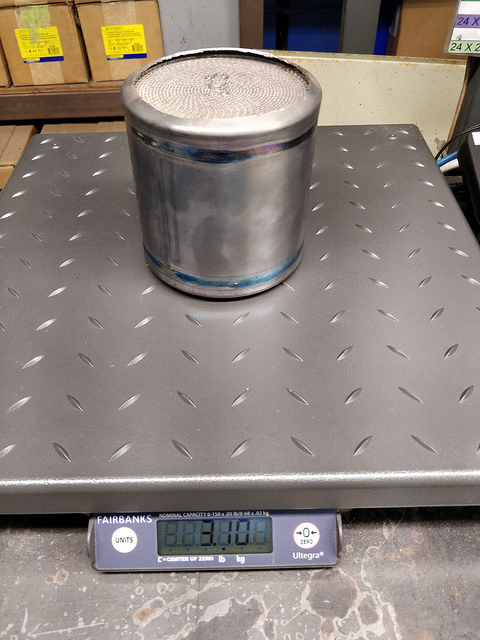

So I hacked the catalyic converter's off... For reference they're 3.1lbs

After a lot of research, I found the exact brand titanium tubing used to make this exhaust, and used the appropriate same brand welding rod to TIG a straight section in place of the cat:

Then I cut the tube in half. Really, the proper way to fix this is with a flex pipe inbetween the two halves, which I may still do. But for now I wanted to get the car back on the road. The cut section leaves a ~1mm gap between the two halves. Using a SS exhaust clamp, I can ensure there is a bit of wiggle room allowed for alignment and minor flexing.

I wrapped the hottest portion of the exhaust and added a bit of fireplace ceramic batting for extra protection. I was going to use the batting on the entire muffler, but I decided that having some airflow past the muffler's outter shell was better than plugging the entire area with the batting.

Regarding the melted driver's side heat shield. I sourced the OEM replacement heat shield, the OEM rivets, and the OEM adhesive (thanks to some help from this forum!)

Done.

Results 1 to 22 of 22

-

10-13-2018 #1Enthusiast

- Join Date

- Sep 2017

- Location

- NJ

- Posts

- 251

Broken AP Ti Exhaust Fix n Picture Heavy

-

10-13-2018 #2Enthusiast

- Join Date

- Apr 2017

- Location

- Miami

- Posts

- 569

I hope I'm wrong but it's more than likely going to crack at your welds again

-

10-13-2018 #3Enthusiast

- Join Date

- Sep 2017

- Location

- NJ

- Posts

- 251

-

10-13-2018 #4Enthusiast

- Join Date

- Feb 2016

- Location

- Bolton, MA

- Posts

- 335

-

10-13-2018 #5Enthusiast

- Join Date

- Oct 2013

- Location

- Washington, IL

- Posts

- 1,739

I thought wrapping the cats promotes premature failure because the heat gets too concentrated?

-

10-13-2018 #6Enthusiast

- Join Date

- Sep 2017

- Location

- NJ

- Posts

- 251

^no cats anymore

If it breaks again, NBD, I can fix with proper flex section next time. It's super easy to work on these things. For now, I'm gonna drive it and enjoy what little good weather we have left up here

-

10-13-2018 #7

-

10-13-2018 #8Enthusiast

- Join Date

- Oct 2013

- Location

- Ohio

- Posts

- 3,889

Let us know how it holds up, good luck.

Last edited by Jack B; 10-14-2018 at 12:44 AM.

-

10-13-2018 #9Enthusiast

- Join Date

- Feb 2015

- Location

- Paradise Valley

- Posts

- 5,481

Great post! Next time though, just go ahead and type out the extra letters Agency Power so everyone knows what you are talking about! LOL

What was the brand of titanium tubing?

-

10-14-2018 #10Enthusiast

- Join Date

- Sep 2017

- Location

- NJ

- Posts

- 251

It's the Quick Jacks 5000 model. -should probably edit your post so it doesn't have all those pictures again. Makes it extra hard for people on mobile to have to scroll thru them all again.

It's Ticon Industries Grade 1 (CP1 or ERTi-1).

-

10-14-2018 #11Enthusiast

- Join Date

- Oct 2013

- Location

- Newmarket, Ontario

- Posts

- 160

Something to consider, most exhaust manufacturers delete the front hanger on the exhaust. Just keep the one near the exhaust tip. The engine moves, you can’t have a solidly mounted front pipe.

-

10-14-2018 #12Enthusiast

- Join Date

- Mar 2016

- Location

- Flower Mound, TX

- Posts

- 799

-

10-14-2018 #13

It cracked up near the header, correct? If so, primarily because the engine will twist(torque) while the supporting rod is trying to hold it in place(front of catback). Remove that front supporting rod and it won't break again. There is too much torque under acceleration for something not to give. The catback will stay in place with out that rod if everything else is tight.

09 ACR With all the goodies

99 ACR TT 99 red RT/10 Roe S/C

97 B/W RT/10 TT 94 RT/10 TT

-

10-14-2018 #14Enthusiast

- Join Date

- Sep 2017

- Location

- NJ

- Posts

- 251

I haven't sourced a Ti flex pipe yet. If I need to replace, I was going to band clamp a SS 3" flex pipe to the Ti tubes.

I haven't heard about not using the front hanger completely. I'm not sure I'm willing to risk something else breaking and having the 400* pipe drop onto the very expensive side sill and roasting that. I haven't looked at other systems, is that what they do - delete using the front hanger?

-

10-14-2018 #15Enthusiast

- Join Date

- Jan 2017

- Location

- Iowa

- Posts

- 592

Needed to purge weld the pipe. The pictures show that the pipe was not purged with shield gas exposing the weld to oxygen from the inside. It may hold up, but the next time the pipe should be purged.

I used to do a lot of walking the cup on stainless food grade tubing earlier in my career.

-

10-15-2018 #16Enthusiast

- Join Date

- Oct 2013

- Location

- Deadmonton, Albertastan, Canada

- Posts

- 1,524

titanium exhaust sounds like a cool idea and all that jazz, but some places have stopped building exhaust, pipes and headers out of titanium due to it just not holding up.

-

10-17-2018 #17Enthusiast

- Join Date

- Jan 2017

- Location

- Iowa

- Posts

- 592

From looking all over the web I’m able to take a guess on keeping the front hanger vs ditching it. If you have the flex pipes between the motor and the front most hanger then use the hanger. If you have headers/ non flex pipe adapter to manifold then don’t use the front hanger. From what I was able to see regarding the titanium AP exhaust systems is that they use no flex pipe and both hangers. I assume this was an oversight on their part and probably doesn’t come up much due to a lot of these vipers not getting driven enough or just not a significant amount of vipers running this exhaust.

Titanium is a great material and really should hold up just as good as stainless. I think a stainless system would run into the same issues if there isn’t room to flex.

Whom ever noticed the front hanger no flex joint is likely on to the root cause. Good catch.

edit: garron and 99RT10Last edited by SilverACR; 10-17-2018 at 10:05 PM.

-

10-18-2018 #18Enthusiast

- Join Date

- Oct 2013

- Location

- Ohio

- Posts

- 3,889

Last edited by Jack B; 10-18-2018 at 12:42 AM.

-

10-18-2018 #19Enthusiast

- Join Date

- Apr 2015

- Location

- Silver Springs FL

- Posts

- 2,399

I always thought it a dumb thing to no have flex sections in an exhaust system. I have been considering cutting a piece of my Belangers out and welding in a flex section.

Glad you fixed it though.

-

10-18-2018 #20Enthusiast

- Join Date

- Oct 2013

- Location

- Ohio

- Posts

- 3,889

-

10-18-2018 #21Enthusiast

- Join Date

- Jan 2017

- Location

- Iowa

- Posts

- 592

All I have seen have the front hanger ditched which would help in regards to flexing and failure. I have heard of collector gaskets failing prematurely which could be either a bad installment or flexing.

In any case poor engineering or installation will lead to undesirable results with any material. Obviously the AP titanium exhaust in this thread met an early demise which falls into one of the aforementioned reasons.

-

10-18-2018 #22Enthusiast

- Join Date

- Oct 2013

- Location

- Ohio

- Posts

- 3,889

The Belanger's are machined flanges which supposedly do not require a gasket, that is wishful thinking, as you said, they tend to leak. I do not think it is flexing just an install issue, I have had the best luck with Belanger's when using a soft copper gasket at the collector flanges, which means two per side.

Reply With Quote

Reply With Quote

Bookmarks