Results 676 to 700 of 863

-

06-17-2020 #676Enthusiast

- Join Date

- Jun 2016

- Posts

- 256

-

06-17-2020 #677Enthusiast

- Join Date

- Apr 2019

- Posts

- 556

Last edited by ViperNC; 06-17-2020 at 02:15 PM.

-

06-17-2020 #678Enthusiast

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 1,677

Long time indeed, good to see you're still kickin' and got the snake as well. Sorry to see about the motor, misery loves company--pull up a seat. And race? Now you speaking my language!

Valvetrain will be upgraded... stay tuned.

Yup I had an oem lifter fail 3 years ago. Debris got into it and it collapsed.

These were upgraded lifters for the Stage II package--but I was one of the early cars and they have since learned a ton and use Delphi lifters from the TA2 LS trans am series race motors.

I think you guys are blowing my personal anecdote out of proportion, from everything I've seen these are pretty rare failures in our cars. Definitely sucked for me, but I wouldn't worry yourselves over it.

-

06-17-2020 #679Enthusiast

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 1,677

-

06-17-2020 #680Enthusiast

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 1,677

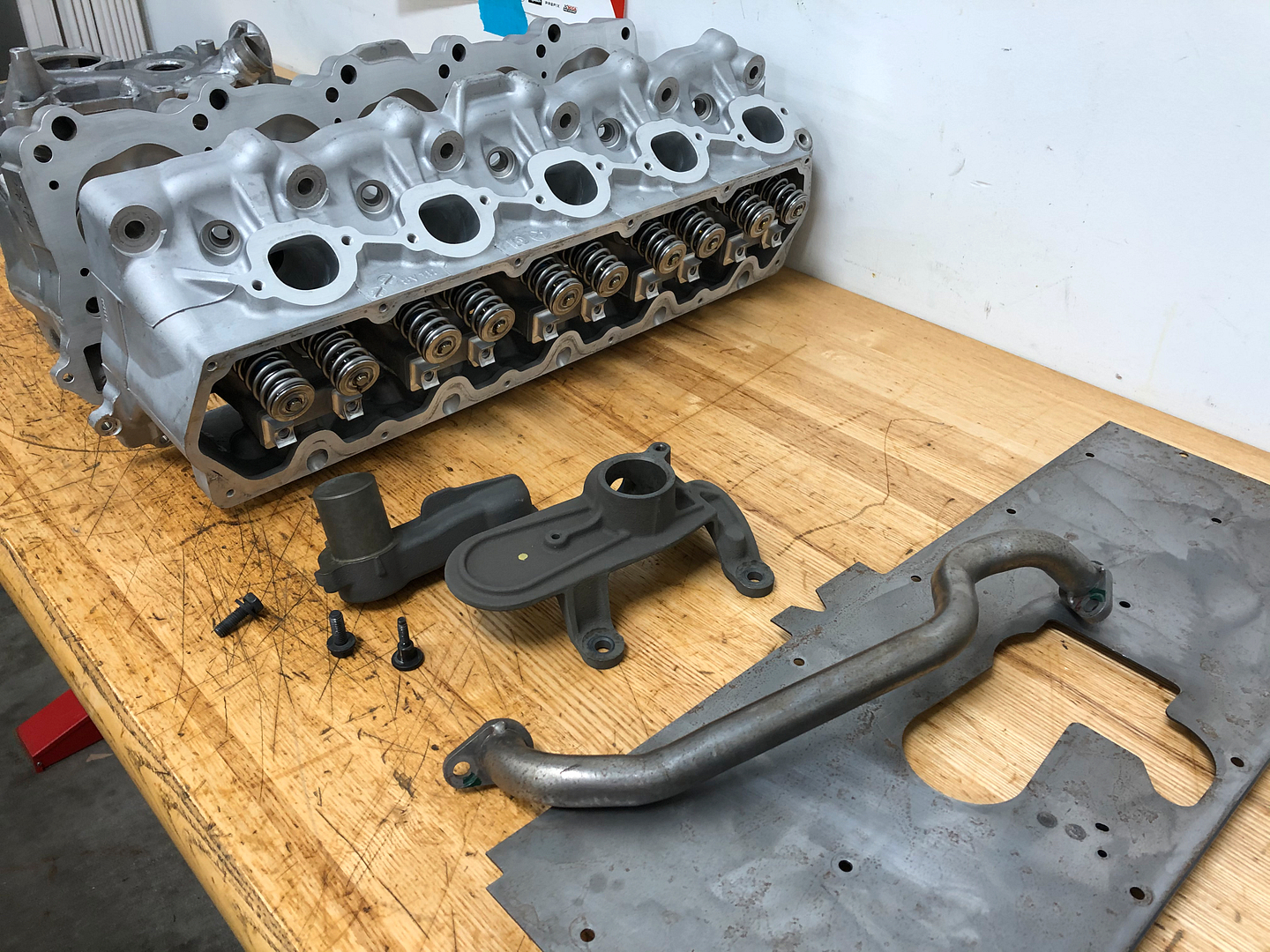

So. I did a lot of soul searching in regards with how to proceed from all of this and about 2 weeks ago finally made a decision. My goal was always to have the ultimate multi-purpose NA street car, so in the back of my head, of course, I always wanted to do the stroker. Now, that being said, I wanted to do it on my terms. I figured some years down the line when the motor needed to be gone through I could plan to do the bottom end. Not quite how it worked out. 2 months into this pandemic while both myself and better half are furloughed from our jobs wasn't exactly the ideal time for me to shell out 30k for an engine build, but, here we are. I was initially very upset about the whole ordeal, moped about for a week or so, and threw myself a little inner-cranial pity party. I soon snapped back into reality and my first world problems, and started to dig in. I figured I'd get quotes to do a stock rebuild (stock bottom end and stage II as it was), and, 9L extreme from Prefix. Depending on the spread between the two, I'd make up my mind. Quotes came back, and financially, it simply didn't make sense to rebuild back to stock. Add to it, the opportunity cost of going back in some years down the road to do the 9L anyway, and, the fact that at least with some upgrades I had something to look forward to (instead of just being angry about), I made up my mind. Motor would go back from whence it came, Detroit, and return with a little more cubes.

VE packaged up my new block and top end, and shipped everything over to Prefix.

-

06-17-2020 #681Enthusiast

- Join Date

- May 2015

- Location

- Watchung,NJ

- Posts

- 504

I like your choice of plans, good luck with everything.

-

06-17-2020 #682Enthusiast

- Join Date

- Oct 2014

- Posts

- 585

Looking forward to your 9L race videos.

-

06-17-2020 #683Enthusiast

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 1,677

So I've been dealing with Scot from Prefix throughout all of this and things have been smooth sailing. He likes to talk almost as much as I do, I think if him, Jon B, and I, were ever on a conference call we'd probably melt the mouthpieces off the phones

In all seriousness I didn't really know what to expect. I had never dealt with Prefix for anything, ever. I had heard (many years back) some negative chatter from a dis-satisfied customer, but also knew of many local guys that have gone through builds with them in recent times with nothing but good things to say. I was hoping my experience would be the latter, and to this point I have zero regrets. Scot always answered all of my technical questions promptly and was giving me status updates/pics almost every day since the motor got there. The one thing I didn't ask when I agreed to the PO was the build time, which, I felt pretty stupid about after we got off the phone. I think at the time I was still pretty bummed out about the whole thing and had a "it'll be done when it's done" attitude. As you'll see, I would be more than pleasantly surprised in this respect.

All of my junk arrived in Detroit last Tuesday (9th of June) looking like Ace Ventura hand delivered it. Thankfully, everything was in ship shape.

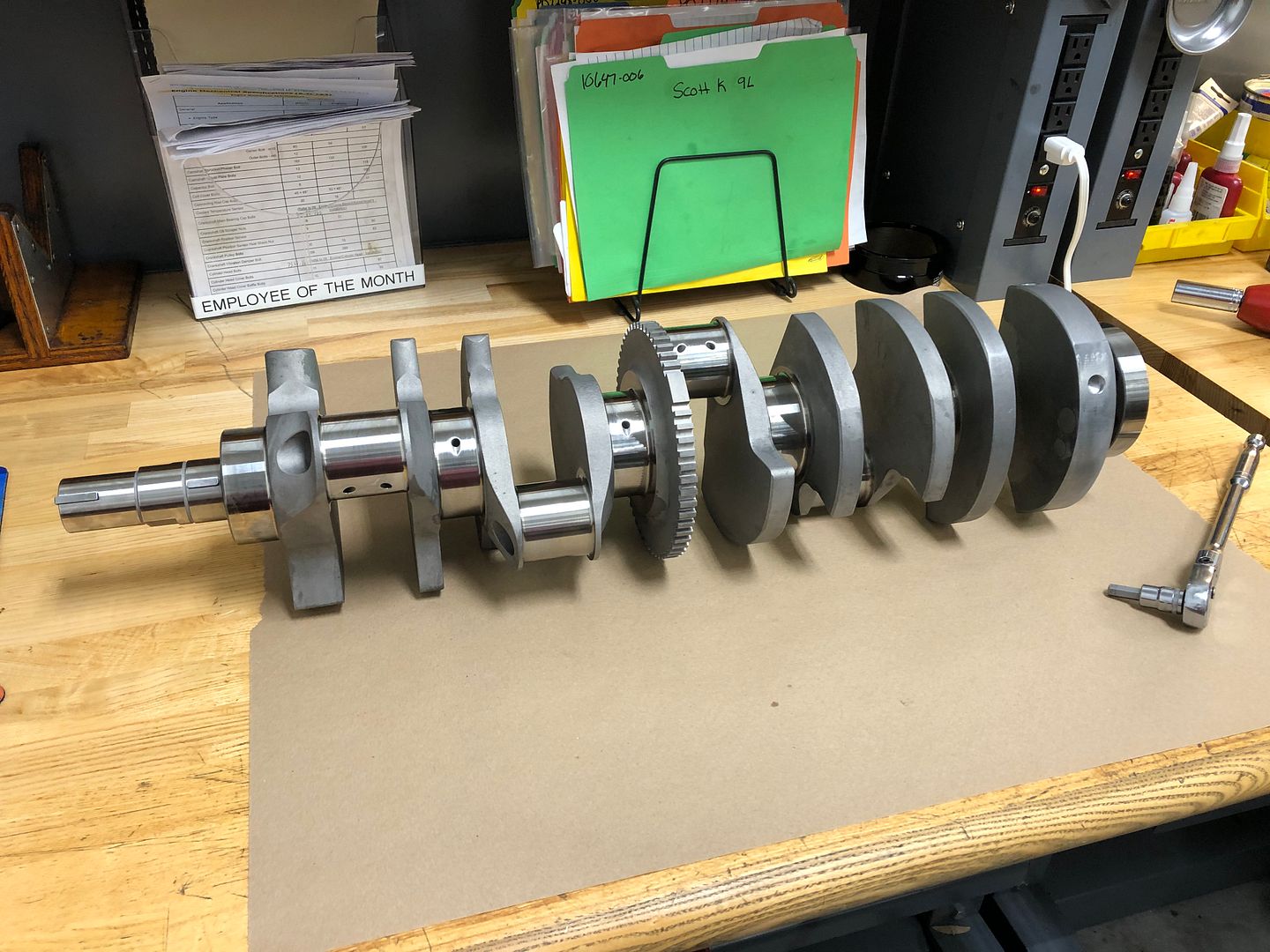

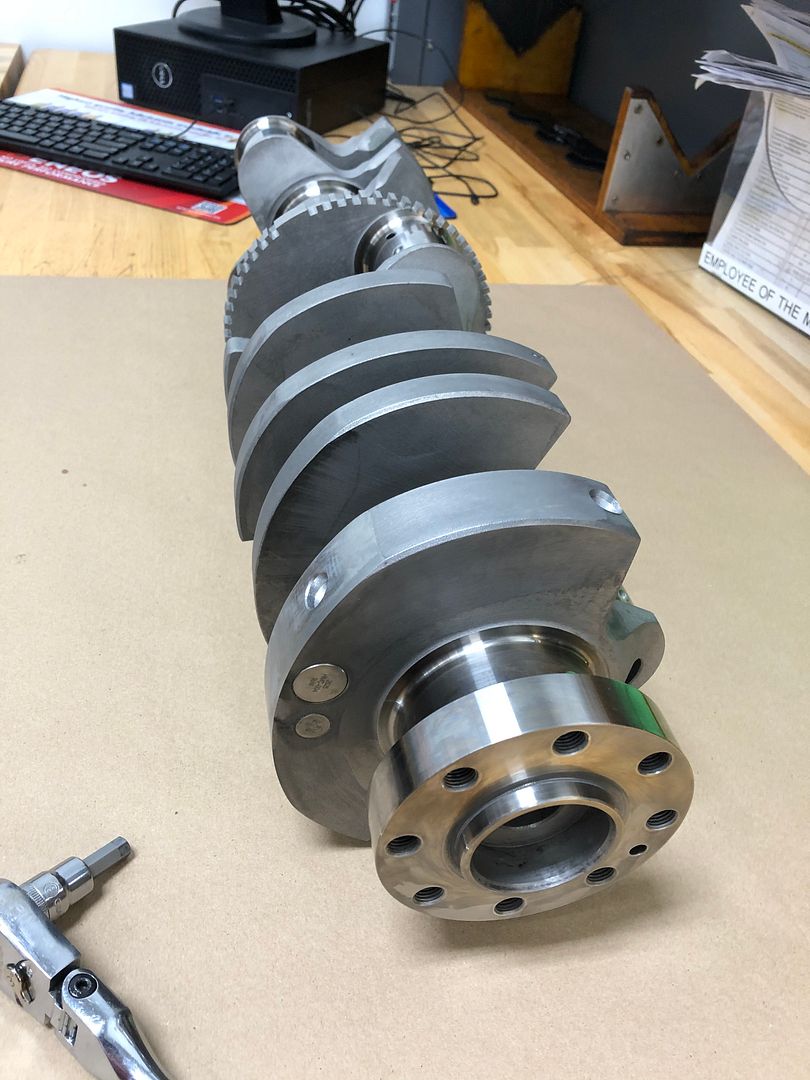

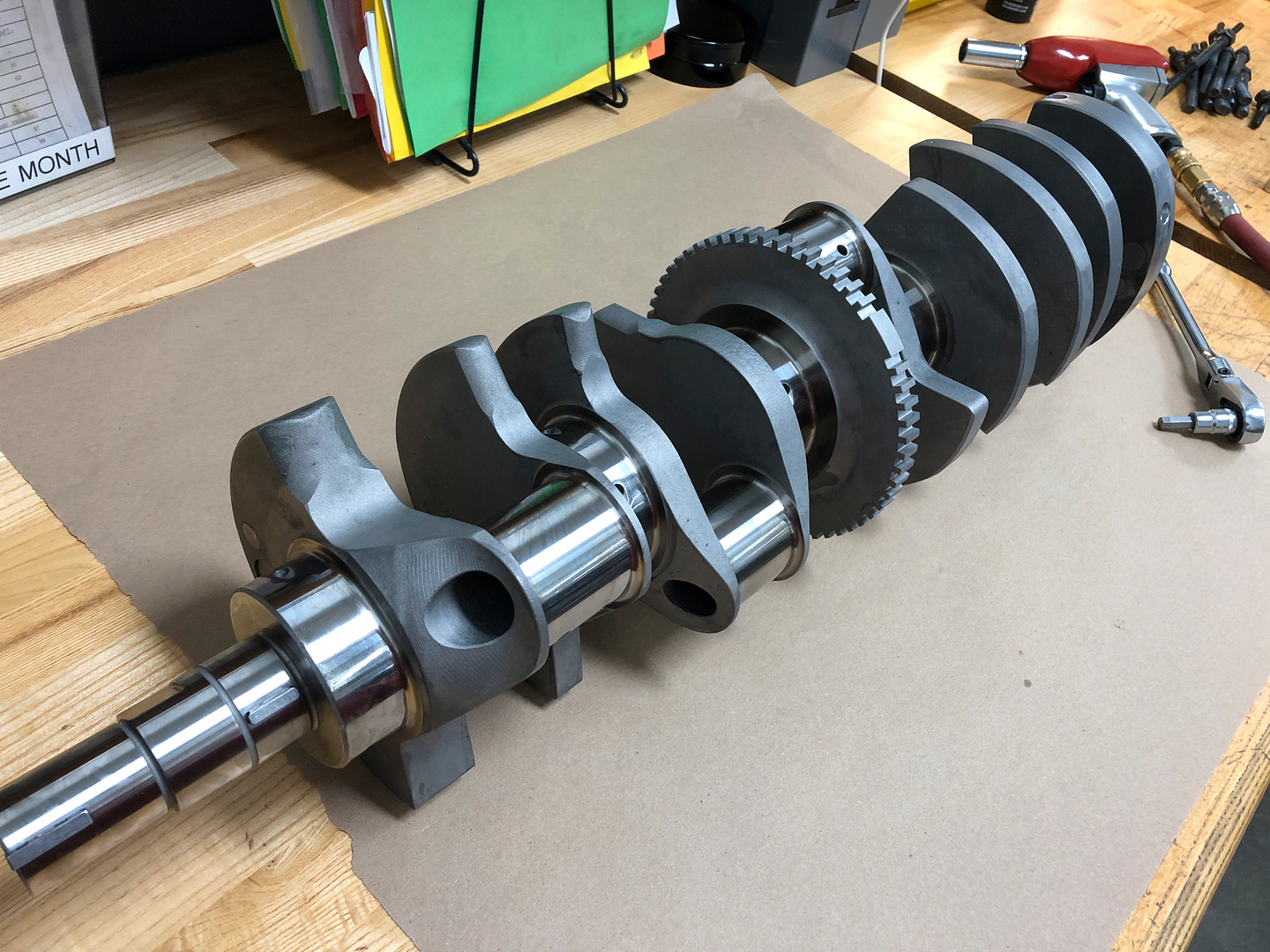

Lets take a look at this engine porn . Fresh gen 4 block;

. Fresh gen 4 block;

Mahle forged pistons, Callies Ultra H-Beam rods;

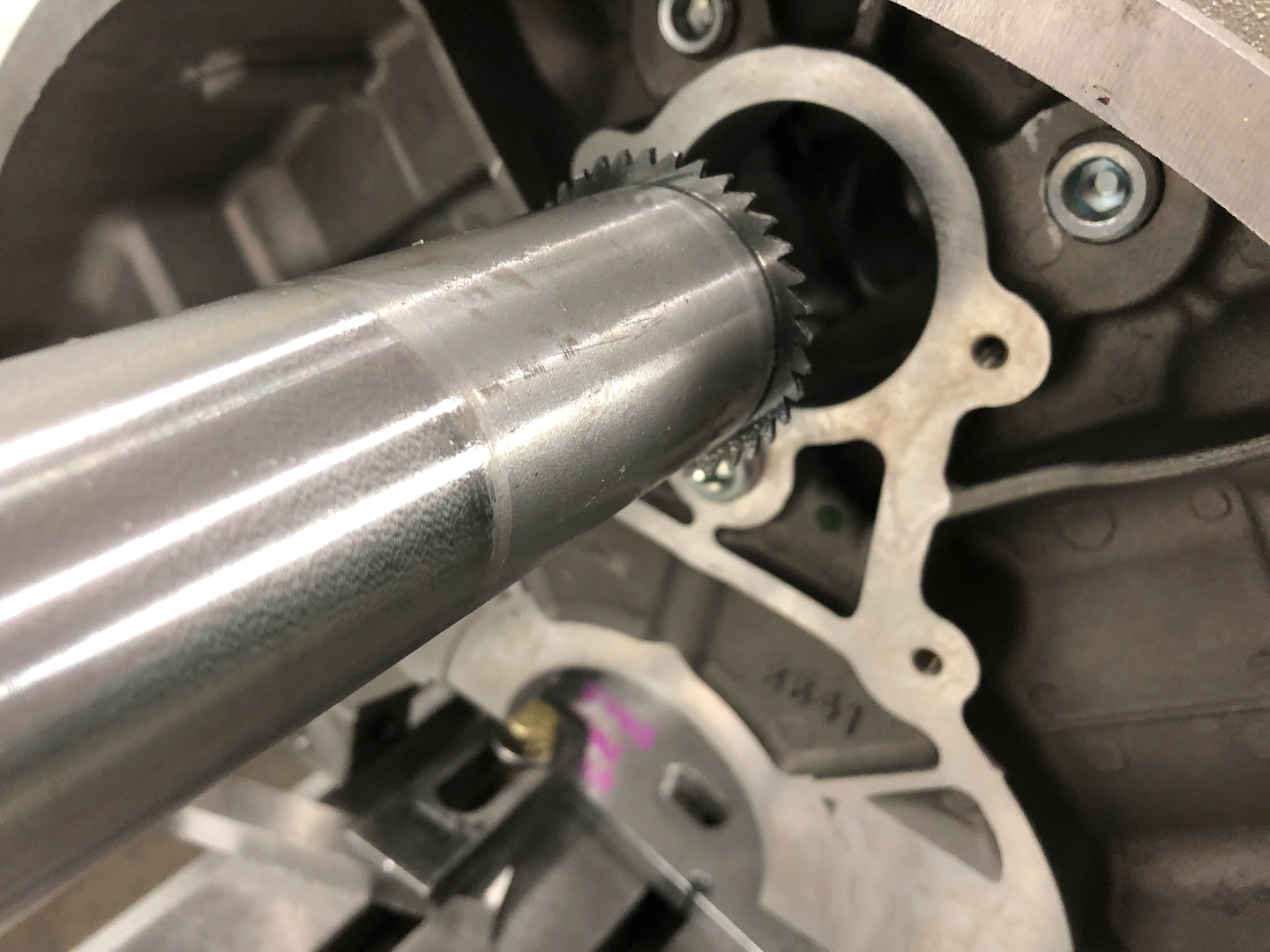

Comp's custom ground "Extreme" cam, new modified crank scraper, and new front timing cover (mine was torn up in the oil rotor housing area and we decided not to attempt a weld repair). The camshaft with its micropolished lobes and the Calico CT-1 journal coating, has to be the prettiest cam I've ever seen in my life;

Last edited by slowhatch; 06-17-2020 at 10:51 PM.

-

06-17-2020 #684Enthusiast

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 1,677

-

06-17-2020 #685Enthusiast

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 1,677

-

06-17-2020 #686Enthusiast

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 1,677

-

06-17-2020 #687Enthusiast

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 1,677

-

06-18-2020 #688Enthusiast

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 1,677

-

06-18-2020 #689Enthusiast

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 1,677

Once bit, twice shy on the valvetrain, or in my case, twice bit, thrice shy. For the new setup, most all 9L builds go with the Delphi hydraulics with ceramic metering ball (left). This is the lifter that is used in the TA2 LS trans am series race engines, it's been proven reliable. There is one step further, and I decided it was worth the money, the Comp short travel link bar style race rollers (right). They are supposed to be the highest stability, highest revving roller hydraulic available. Take a look at the difference in section area above the bushing in both of those lifters, definitely a stress concentrator, and where my overload failure occurred.

The failure which cost me a motor...

-

06-18-2020 #690Enthusiast

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 1,677

You can see the difference in construction between the intake/exhaust side rockers on the gen 5. The closed end style with drawn cup (exhaust), and open roller design (intake). The exhaust side are the ones people have experienced failing (myself included), the trunion cap cracks and spills the bearings into the motor. Scot was telling me because of the valvetrain geometry there is some eccentric loading on the exhaust side rocker so they are more prone to failure. You can notice this in the assembled pics below looking at the rocker from above (the rocker tip is off-center from centerline). The intake side loads squarely however, and seem to never have issues. For the new build we went with the CHE bushing upgrade on the exhaust side (eliminating the needle bearings altogether), and left the intake side OEM (though disassembled, inspected, and cleaned).

Last edited by slowhatch; 06-18-2020 at 01:17 AM.

-

06-18-2020 #691Enthusiast

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 1,677

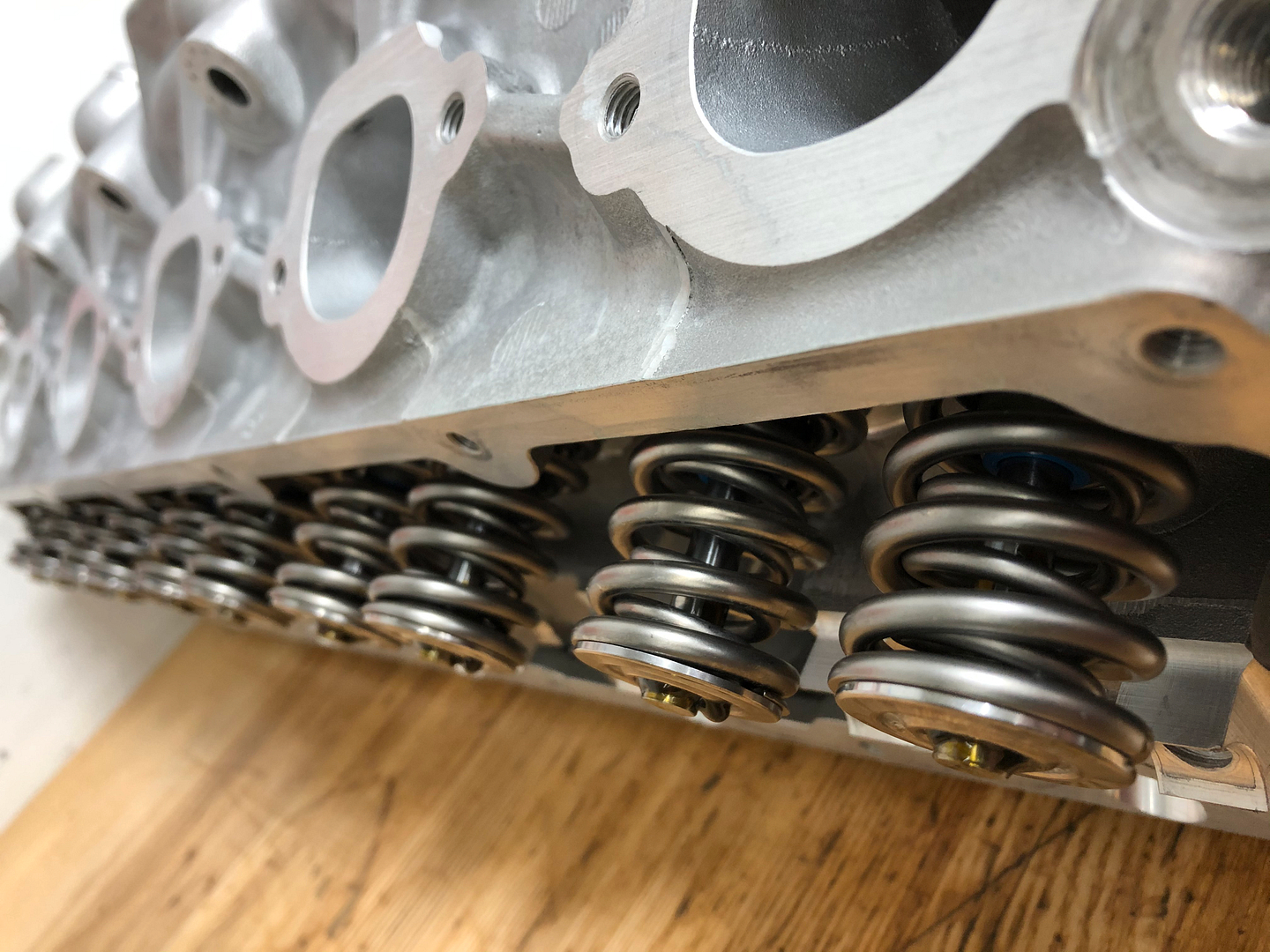

By Monday of this week we had semblance of something that looked like a real motor

Valvetrain is in, lash and preload are set, we are just some small bits away from completion. New water pump was installed (since Morgan noted my old one was weeping slightly during disassembly).

Can clearly see the trunion upgrades on the exhaust rockers here;

Just a few bits left...

-

06-18-2020 #692Enthusiast

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 1,677

-

06-18-2020 #693Enthusiast

- Join Date

- Mar 2015

- Location

- Alberta Canada

- Posts

- 1,686

Wow, that's one hell of a turn around!

And I agree, if I was I your position, I would do the same, try to make a positive out of a negative.

-

06-18-2020 #694Enthusiast

- Join Date

- Oct 2014

- Posts

- 585

Wow! Talk about a quick turn around.

-

06-18-2020 #695Enthusiast

- Join Date

- Feb 2019

- Location

- CT

- Posts

- 736

You CAN NOT go wrong with the Callies internals. You get what you pay for. Forged and machined in the US of A. None of this forged in China and machined in USA crap...like all others out there. Good luck!!! We want the videos!!! That 9L package is tempting. You're committed to her now.

Last edited by Gen5snake; 06-18-2020 at 09:07 AM.

-

06-18-2020 #696Enthusiast

- Join Date

- Apr 2019

- Posts

- 556

I track my car, too hence the concern. After reviewing my build sheet from Prefix yesterday, I've got the Delphi lifters they are going to install for your build. Nonetheless, I might make a point to check these periodically. Better safe then sorry. You're going to love the 9.0L from Prefix. I know I do.

-

06-18-2020 #697Enthusiast

- Join Date

- Feb 2019

- Location

- CT

- Posts

- 736

-

06-18-2020 #698Enthusiast

- Join Date

- Apr 2019

- Posts

- 556

-

06-18-2020 #699Enthusiast

- Join Date

- Dec 2018

- Location

- The Front Range

- Posts

- 137

Amazing progress here. Great job documenting too; really enjoy following your threads.

-

06-18-2020 #700Enthusiast

- Join Date

- Feb 2019

- Location

- CT

- Posts

- 736

Good call. The problem here is when you see it, it's too late...it' looks like Alex's engine. Honestly even xray wouldn't find this problem. Usually what happens is the several needle bearings, in the lifter roller, bind at full lift and that force causes the axle to split the lifter body. The best would be to go to a solid bushing...just my opinion. I wouldn't tangle with needle bearings anymore. Failure is too costly.

Reply With Quote

Reply With Quote

Bookmarks