With a Viper we are targets for speed enforcement. Let's face it, if an officer has to choose between a Viper and a Camry, you are getting the radar/laser gun pointed at you. I decided to install a concealed radar/laser detector. I got around to the installation of the Escort Passport 8500ci Plus system into my 2002 Viper GTS over a weekend. It took me a while more than anything because of weather and some fab work that I did to mount the receiver/sensor on the front. We got pounded a couple of times over the weekend with some downpours and, even though I setup my little shelter, it slowed me down.

So in order to make this as clear and as easy as possible, I'll detail some things so that you know what you are looking at depending on whether you match what I did, take it down a notch or two, or go way beyond what I did. The whole install took me about 4 hours including the fab work. The majority of what you will read below is the mounting of the sensor itself as this is the most complicated part. Other than that, the rest is easy.

As you will see below, I did not remove the facia to do this. I did however mount the front radar/laser sensor very securely. I'll detail how I did it in the writeup. There are different ways to accomplish what I did, but since I had certain tools in the chest (mostly from a corvette restoration we are in the midst of), I took advantage and used them. Other than the typical hand tools, the only other thing I needed was a pop-riveter and a flexible drill extension to drill too small holes to attach the sensor. Again, the details below will make everything clear.

OK what's in the shot below is what will be going into the car. Clockwise from the top left:

Radar/Laser Sensor

Control Unit

Keypad/Display

GPS Antenna

The kit comes pretty complete in terms of wiring. All the components plug into the control unit with modular plugs so it is easy. Not much cutting or splicing needed except for the power. You also get a bracket to mount the radar/laser sensor, but for the Viper, I found that to be useless. You get an array of screws, two face tape and velcro. In short, you have options and they cover the bases pretty well.

There is also an LED that is included with the kit but to do that properly, in my opinion, you should be drilling into a location and running that through the dash at some point. Someplace that would be visible while driving. Since I did not intend to do that, I left it out. I tend to rely on the warning sounds and display anyway. I am also used to a windwheild mount anyway, so, to me, it's not required.

The first thing I did was to decide where the control unit would be located. Since the unit has the speaker for the audible warnings, I needed it to be in a place where I could hear the warnings. In other words, under the seat or under the console was out of the question because you would muffle the sound too much. I could go with an external speaker (Escort has the option) but I preferred to try it this way first. For me the best place was under the dash on the left side of the foot well. There is a flat empty area tucked up behind the fuse panel that leaves the speaker exposed. So, essentially, I would run the wires to the drivers side behind the fuse box. Once that is chosen, I decided to move onto the most complicated part of the install, the radar/laser sensor.

If this was only a radar sensor (ie: no laser detection) you could mount the sensor behind the platic facia for a true stealth mode. Howver, since they use laser quite a bit in Florida now, I need to get laser detection. I decided to mount the sensor in the middle portion of the front facia, on the passenger side of the crosshairs. The driver's side has the hood release, so the passenger side gets the sensor. You have a good strong place to mount it, the rigid composite material behind the facia.

The rigidity of the mounting point allows me to really cut out vibration so I decided to mount it very well. The built in brackets/wings on the sensor itself do not reach the composite material. You have to add a mount that will drop below the facia. What I decided to do is make my own small brack from a piece of 3/4 square aluminum bar. It is hollow. I basically took the bar and cut a length that was about 2 inches wider that the sensor tabs. I then cut notches on the bar to create the tabs. The rough bracket is below.

I then took the screws from the kit (fine threaded stainless) and I drilled and tapped the bracket to match the sensor tabs. There is enough there to tap and since the sensor is light, the two screws with locktite will be plenty. The tapped bracket:

I then sanded and finished off the bracket with some primer and paint to get a flat black finish that would be lost in the shadow of the facia and radiator area. Note the pilot holes on the tabs. These are there to pop-rivet it in place. That will be the next step. Not too shabby if I do say so myself...

Results 1 to 8 of 8

Thread: Escort Passport 8500ci

-

01-01-2014 #1

Escort Passport 8500ci

Luis V.

Miami, Florida

2002 Dodge Viper GTS - FE #298 & 2013 Dodge Viper GTS

-

01-01-2014 #2

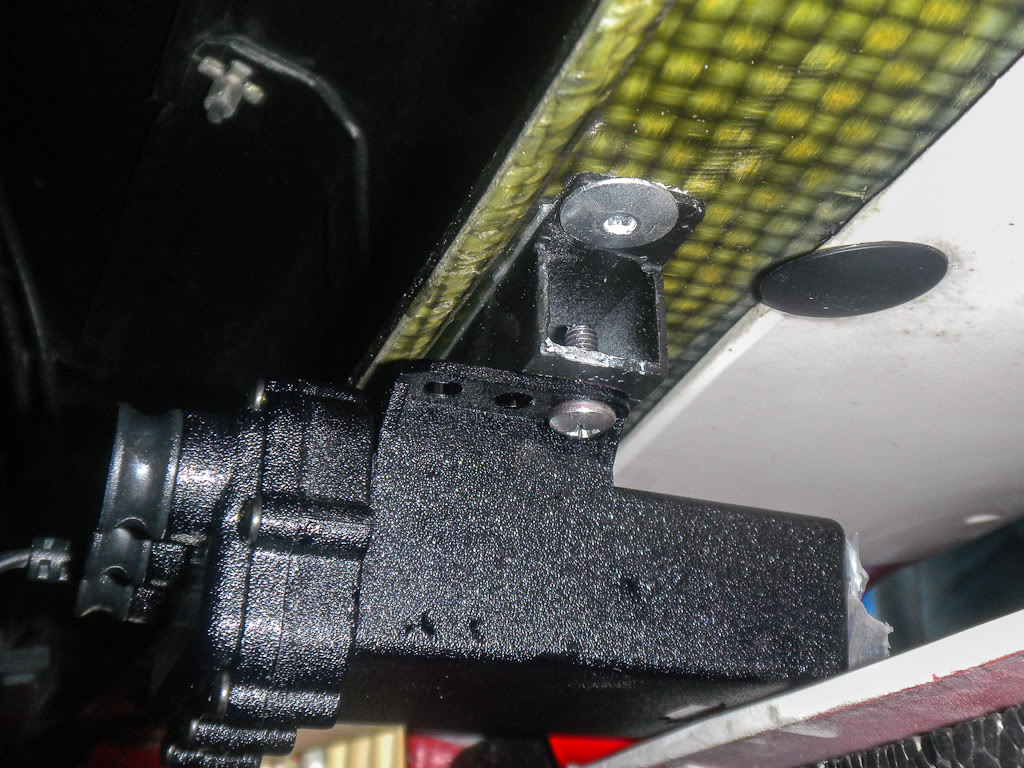

Now to mount the bracket, I used a waterproof, heat resistant, two faced tape from Loctite. I also used pop-rivets to secure it. What I did was apply two face tape to the bracket and I mounted it square to the front of the car. In other words, perpendicular to the motion of the car when on the road. You have some small amount of play in the sensor tabs so that you can perfect the position on the sensor. Once I decide on the position, I mount the bracket with the tape. Now to drill the holes to pop-rivet the bracket in place. That I did using a flex adapter in front of the drill. I have an air drill so it is small enough to get in through the facia. (I wrapped it in a rag to be safe anyway) Once in there I use the pilot holes in the bracket as a guide and drilled to small holes to slide the pop-rivets up into the composite material on the car. Below is the shot with the pop-rivet placed in there. Below that is the hand tool to pull the rivets tight. (I have a air riviter, but no way it fits... so I had to do it by hand.

Here are a shot with the bracket in place and riveted down.

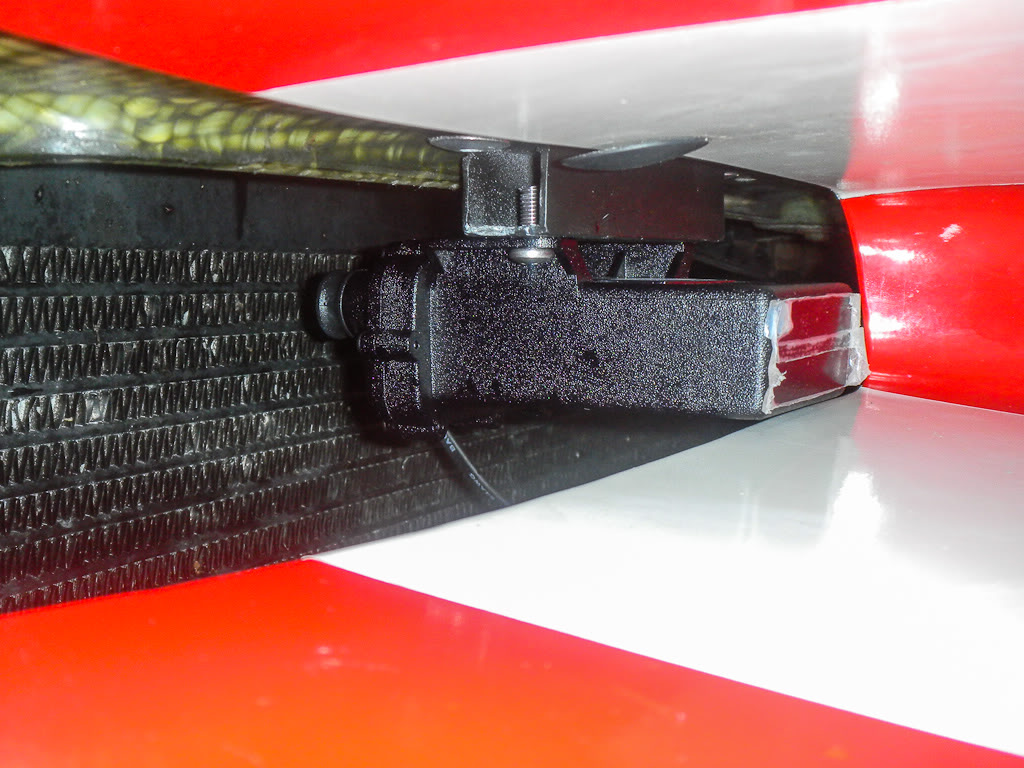

Now it is just a matter of mounting the sensor to the bracket. I used two of the supplied screws and simply mounted the sensor to the tapped holes. I use a couple of drops of red Loctite. (thread lock). This mount is as solid as it can get, as far as I am concerned. A few shots of the unit mounted. The shots are a bit decieving. The facia is not actually touching the sensor. There is a gap there.

Luis V.

Luis V.

Miami, Florida

2002 Dodge Viper GTS - FE #298 & 2013 Dodge Viper GTS

-

01-01-2014 #3

Now the next part is not rocket science... You have to run the cable back to the driver's foot well behind the fusebox. I used a coule of tie down pads at the front to get started. I also put the wire in a loom starting just before I go around the radiator. I seal off the ends with electrical tape to secure the loom to the wire and to keep anything unwanted out of there. (insects, dust, ect).

Looking from above down over the airbox on the car, you can remove the baffle that directs air to the radiator. This is just a plastic plate held in place with four screws. (It is the plastic under the cable in the shot above. Once that is out you have a view of the area to mount the pads and tie wrap the wire.

Around the radiator and under the hood hinge I tie wrapped it down to the wire harness that feeds the headlights. Hard to see in the shot, but you'll get the idea.

Follow the wire harness around the front driver wheel well...

Down the back of the wheel well under the brake booster and booster cable access to the side of the car.

I run the wire under the metal plate (still in the loom) and out just under the booster cable hookup on the driver's side.

Luis V.

Luis V.

Miami, Florida

2002 Dodge Viper GTS - FE #298 & 2013 Dodge Viper GTS

-

01-01-2014 #4

Now the wire should be right at the door hinge (essentially). You have to get in through the firewall. The easiest access I found was the rubber grommet that feeds the wires to the door. It is easily accessed by removing the hinge cover right in front of the door. It is the part that makes up the inner portion of the gill on the side. In the shot above, it is removed. The grommet is just below the hood hinge on the driver's side. It comes off pretty easily so no worries. The shot below is the location of the grommet looking from above. The hinge cover is still in place in the shot below.

I pull off the rubber grommet and simply feed the wire in by hand. The modular plug fits through easily. As you feed it through you should have it end up in the floor in the driver footwell. Real easy! I then put some silicone sealant around the wire and on the bottom edge of the rubber grommet. Don't go nuts with this. You are just putting it in to seal the wire there so no moisture gets in. It should not be a problem. If you overdo it, the grommet can seal in place making it hard to remove if you ever need to run a new wire. For example, when I add the laser shifters one day... LOL...

The shot of the wires and an idea of how much silicone I put on.

I then cut the loom and tape seal this end so that the taping is hidden behind the hinge cover I will be putting back in place. When I put the cover back on, I run the wire through the notch (it was there on my cover as if they expected me to use it...LOL) and you end up with the shot below.

The GPS antenna is next.

Since the car is a non-metallic body, you can mount the GPS antenna under a body panel. No need to show it or have it glued outside. What I did was pull off the rear window weather stripping carefully and that gave me access to the roof liner. If you are careful you can move your hand in there passed the "roll bar" and feel for the first clearing to the body panel. I put it under the passenger side towards the back of the "double bubble". I simply put two face tape on the top (plastic side) of the GPS antenna and taped it to the roof panel. When the roof liner comes back up it, pretty much, pins it in place. The orientation of the antenna has to be right. If you flip it over you will get bad readings. In short, glue the top of the antenna to the underside of the roof panel. You're golden. Signal is as strong as it would be if outside. Best part, nobody will ever know it is there. Since I can't get a camera up there, I shot this to give you the concept.

That amazingly handsome fellow in the shot is my 5 year old son that loves to check out what I am always doing to the cars. It helps to have him around though... he's the perfect size to get in the foot wells! LOL.... Just kidding...

Once the antenna is up there, we run the wire back to the control unit. Remember that is in the driver's footwell. So the path I chose was to go down the door pillar, under the sill and back up to the fuse box area. Not real hard. The one thing I recommend is that you run a snake (wire hanger) bent a bit over from the driver's side to the center of the rear hatch between the hinges of the glass. Tape the connector to pull it and your done. If you reach up carefully you can tie wrap the wire to the harness that feeds the defroster. Easy way to keep the wire where you want it.

One other note... the GPS antenna wire is insanely long. Long enough to wrap around the entire car. I am not a fan of cutting the length on antenna wires so I simply estimate the length I needed to get to the front of the car and then wrapped up the excess in a long loop (2 feet) and tucked it under the roof liner behind the roll bar. I tie wrapped the loop to make it tight and reattached the roof liner. Perfectly neat and no cuting of the antenna wire.

The path I followed to the driver's side.

You can push the wire up under the carpet in the door jamb up to behind the fuse box easily.

- - - Updated - - -

We're getting there... Since the power source is the fuse box and the controller is right behind it, I cut the power leads to give me about 12 inches of slack. I then soldered an "add-a-circuit" to the positive cable coming from the control box (it has the in-line fuse) and heat shrunk it to cover it well.

The ground got a terminal added to screw it to one of two small screws right under the fuse box.

I run the wires up under the dash to come to the fuse box from behind. I use fuse position 6 to get ACC power. Make certain to use the same fuse you pulled from the fuse 6 location in the "add-a-circuit" and then I add a 5 amp fuse for the power lead going to the control unit. The in-line fuse they have is a 2 amp so the circuit is double fused and plenty safe.

The last item to run is the display unit. I placed it right at the joint between the radio/center bezel and the knee pad (removed in the photo below) so that I did not have to drille through anything. It will sit in front of the shifter and looks very clean there. If I want to go way overboard (quite possible with me) I may make a fiberglass "enclosure" for it and wrap it in vinyl to match the interior and add it to the knee pad. Overkill... but for now, it will be in front of the shifter.

I just noticed I did not have a shot with the display mounted... I'll get one later and add it...

The wire for it runs under the air duct on the knee pad and then follows a wire harness behind the fuse box to the final destination on the side of the footwell.

The last thing was connecting everything (I had tested it while doing the install to make sure it all worked befoer the final mounting) to the control box, tie wrapping all the wires neatly and mounting the box to the side with high strength velcro. The final location with the install complete.

The reason I mounted with velcro is that I wanted to be able to pull it off as needed. The reason is that because of the GPS, the unit has a built in database that can be updated. The database has red light camera locations, speed camera locations, etc that are updated regularly. That is done with a PC and a USB cable. By being able to remove it for a minute, I can update it easily and place it back securely. I preferred this instead of having to run a USB port someplace.

That's it!Luis V.

Miami, Florida

2002 Dodge Viper GTS - FE #298 & 2013 Dodge Viper GTS

-

01-01-2014 #5Banned

- Join Date

- Oct 2013

- Posts

- 621

Best not to speed at all. In a Viper you always look like you are going fast even when parked, so really no need to speed.

Additionally, I have never run into a cop with a radar/laser gun while on the race track or drag strip.

EXCELLENT write up.Last edited by KRATEDISEASE; 01-01-2014 at 03:57 PM.

-

01-01-2014 #6Enthusiast

- Join Date

- Jan 2022

- Posts

- 0

Great write-up, thanks for posting!

I love my GPS-enabled 9500ix. Also love the fact that the CHP still uses a ton of Ka band

-

01-01-2014 #7Enthusiast

- Join Date

- Oct 2013

- Posts

- 170

I always feel like I'm going too slow.. radar is a must..

Good job buddy

-

01-01-2014 #8Enthusiast

- Join Date

- Dec 2013

- Location

- Merritt Island Fl.

- Posts

- 335

Just bought a V1 and love it, it has saved me a couple of times already, going to wire in the power wire and get rid of the coiled cord.

Reply With Quote

Reply With Quote

Bookmarks