Results 151 to 175 of 412

-

09-09-2015 #151Enthusiast

- Join Date

- Jan 2015

- Location

- United Arab Emirates - Abu Dhabi

- Posts

- 130

-

09-09-2015 #152Enthusiast

- Join Date

- Oct 2013

- Location

- Houston, TX

- Posts

- 3,005

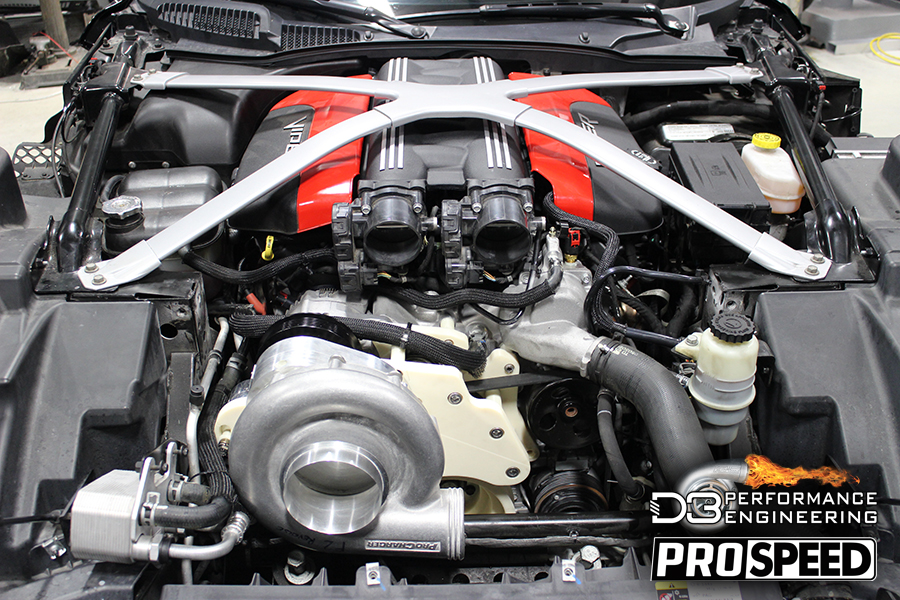

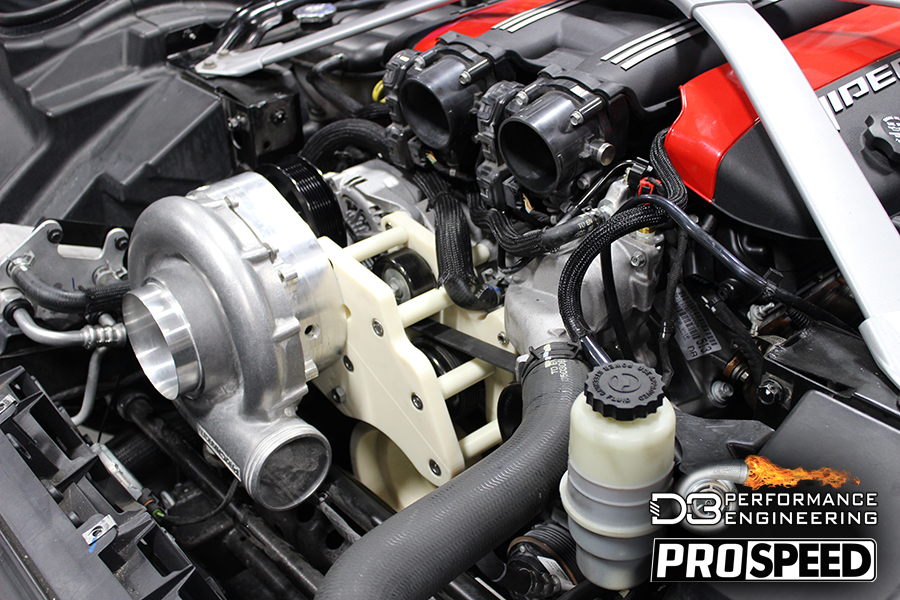

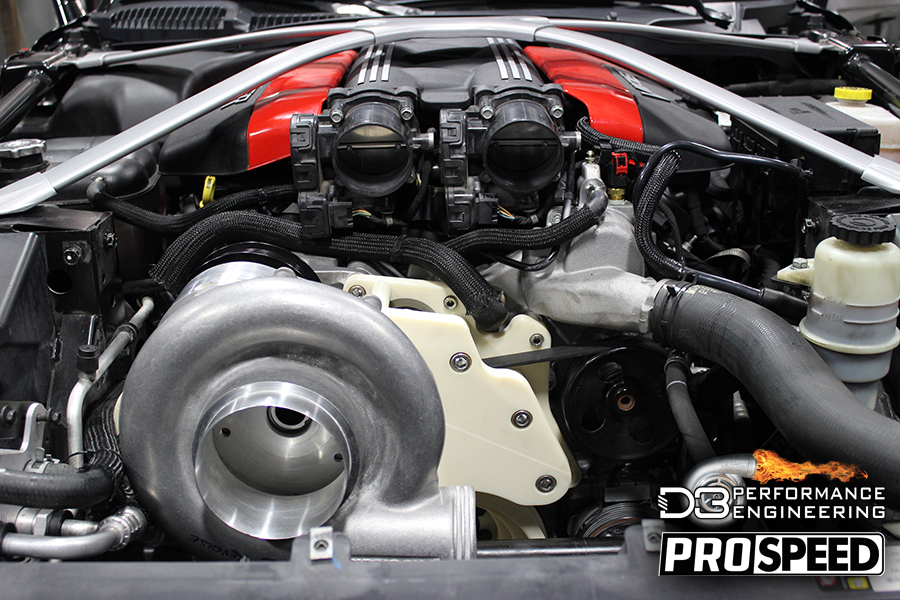

It isn't just a matter of the rib count. Has more to do with the surface area that this belt covers around the blower pulley, and the crank pulley. From the photos, both pulleys are large diameter (good) and the idler/tensioner design has maximum circumference belt-wrap in mind. PSI is also a measure of restriction, not a good relative indicator vs belt friction. Most Gen 3 Paxton cars can achieve 12-14 psi with a simple green Gates belt, and that is on a much smaller blower pulley size. The Viper engine makes 900+ rwhp at those boost levels.

-

09-09-2015 #153Enthusiast

- Join Date

- Nov 2014

- Posts

- 356

-

09-09-2015 #154

-

09-09-2015 #155Enthusiast

- Join Date

- Dec 2014

- Location

- Texas

- Posts

- 285

-

09-09-2015 #156Enthusiast

- Join Date

- Nov 2014

- Posts

- 356

-

09-09-2015 #157Enthusiast

- Join Date

- Dec 2014

- Location

- Texas

- Posts

- 285

-

09-09-2015 #158Enthusiast

- Join Date

- Jan 2014

- Location

- Townsend TN

- Posts

- 269

-

09-10-2015 #159Enthusiast

- Join Date

- Jan 2015

- Location

- United Arab Emirates - Abu Dhabi

- Posts

- 130

-

09-10-2015 #160Enthusiast

- Join Date

- Oct 2013

- Location

- Houston, TX

- Posts

- 3,005

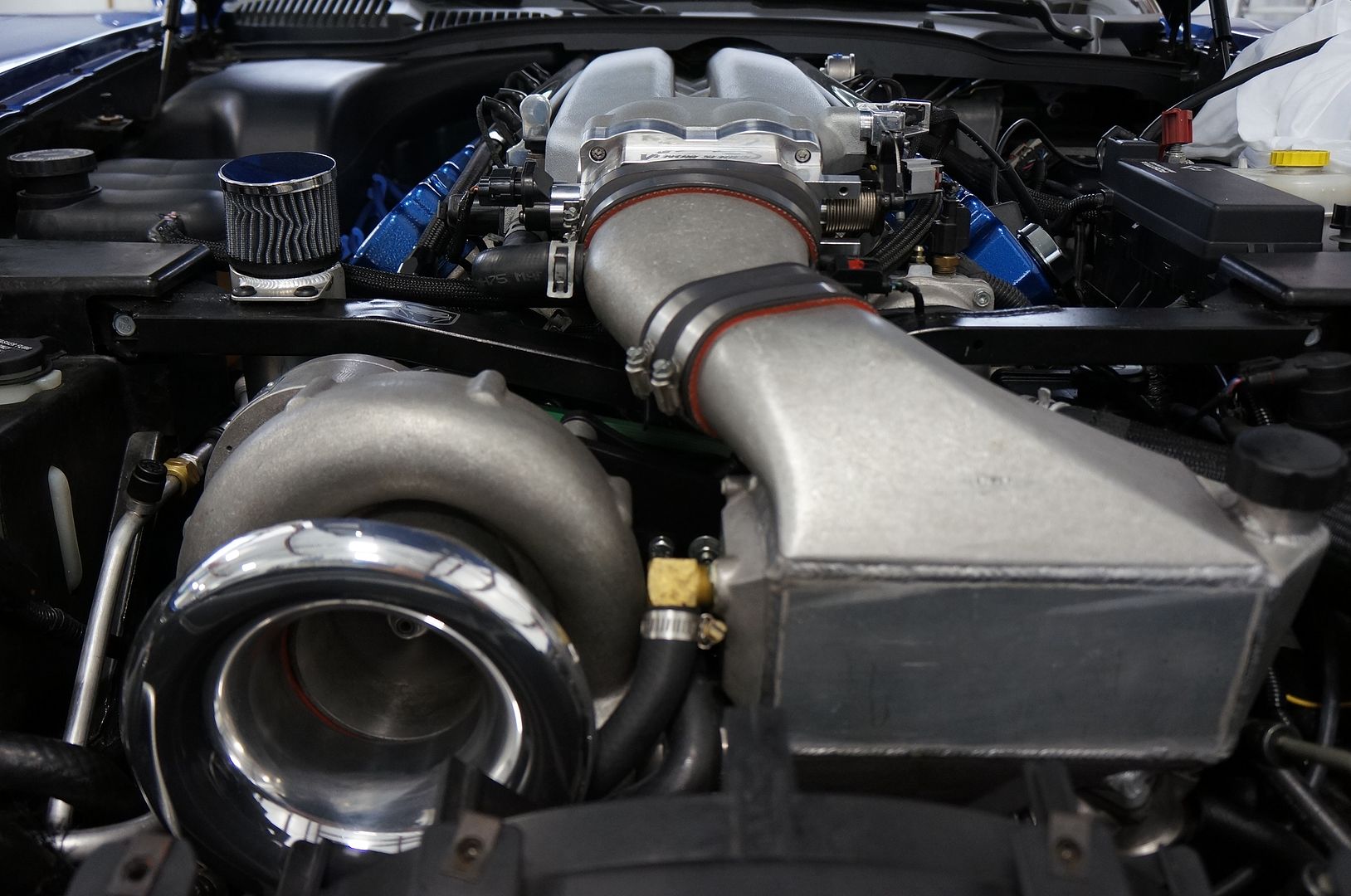

As funky as the Paxton airbox looks, it still flows a lot of air and uses the hood scoop to feed it. I've dyno'd and ran the drag strip with the bellmouth in place, as well as the airbox. No performance difference. The bellmouth just looks cooler, but filtered air is better. haha

-

09-10-2015 #161Enthusiast

- Join Date

- Nov 2013

- Location

- Clearwater, FL

- Posts

- 1,521

-

09-10-2015 #162Enthusiast

- Join Date

- Nov 2014

- Location

- Bay Area, CA

- Posts

- 1,053

-

09-10-2015 #163Enthusiast

- Join Date

- Nov 2013

- Location

- Clearwater, FL

- Posts

- 1,521

Sorry...I meant 140whp http://driveviper.com/forums/threads...-running-right

-

09-11-2015 #164Enthusiast

- Join Date

- Nov 2014

- Posts

- 356

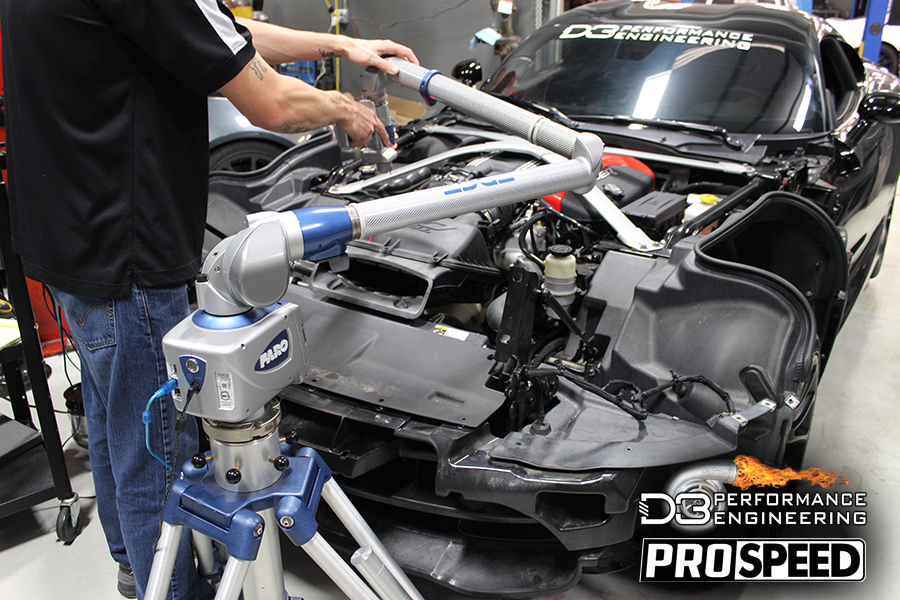

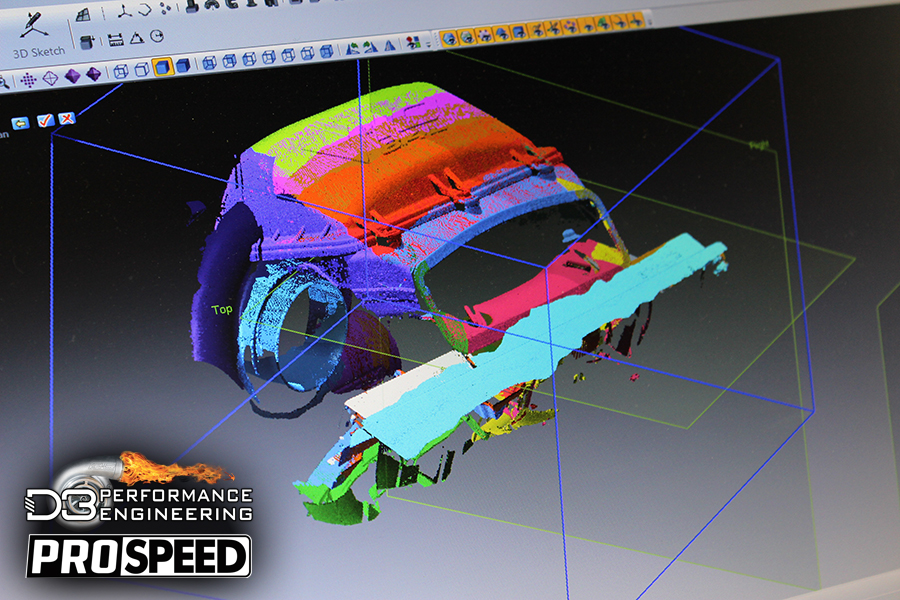

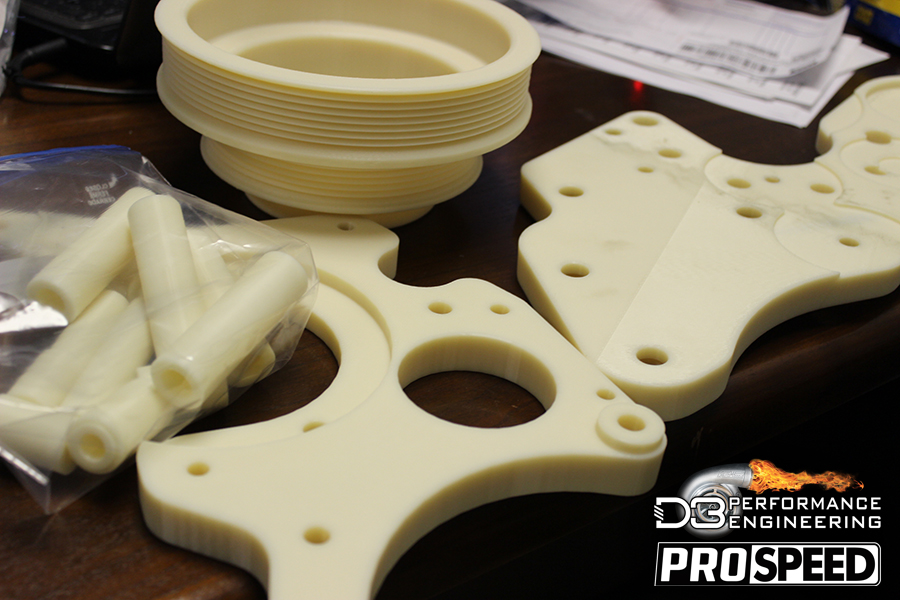

Now that the brackets and pulley are out at the CNC, we started with the intake design. We installed the OEM airbox then scanned it to know our height limitations along with the point which meets the hood. Then we removed it and scanned the inlet of the supercharger for routing and the radiator fans for depth limitations.

-

09-11-2015 #165Enthusiast

- Join Date

- Sep 2015

- Posts

- 73

Pretty awesome that you guys are documenting this!

-

09-11-2015 #166Enthusiast

- Join Date

- Feb 2015

- Posts

- 299

You guys Rock!!

-

09-12-2015 #167Enthusiast

- Join Date

- Sep 2015

- Posts

- 566

Very excited to see the outcome... Good job D3

-

09-12-2015 #168Enthusiast

- Join Date

- Oct 2013

- Location

- Houston, TX

- Posts

- 3,005

-

09-13-2015 #169Enthusiast

- Join Date

- Apr 2015

- Posts

- 463

Running around without a filter is a very bad idea

-

09-13-2015 #170Enthusiast

- Join Date

- Feb 2015

- Posts

- 299

-

09-13-2015 #171Enthusiast

- Join Date

- Oct 2013

- Location

- Edmonton

- Posts

- 784

-

09-16-2015 #172Enthusiast

- Join Date

- Nov 2014

- Posts

- 356

Goodies on the way from Nitrous Outlet just for kicks

-

09-16-2015 #173

-

09-17-2015 #174

-

09-18-2015 #175Enthusiast

- Join Date

- Feb 2015

- Posts

- 61

Hey Evan, the intake pipe it will be twin pipe from the intercooler to TB or single pipe from intercooler then Y pipe to TB.

Thanks,

Khaleefa.

Reply With Quote

Reply With Quote

Bookmarks